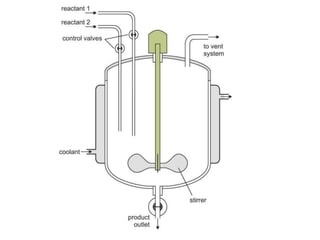

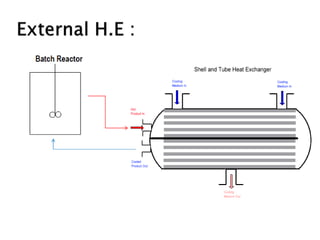

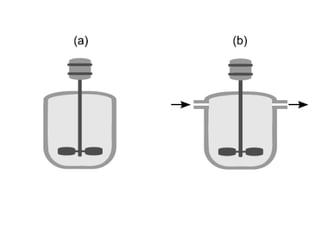

A batch reactor undergoes a controlled chemical reaction within a contained vessel. Reactants are added at the start and nothing is added or removed until the reaction is complete. Semi-batch reactors are similar but allow reactants or products to be continuously added or removed during the reaction. Batch reactors are useful for small scale or specialized productions like pharmaceuticals due to their flexibility, but they have higher operating costs than continuous reactors.