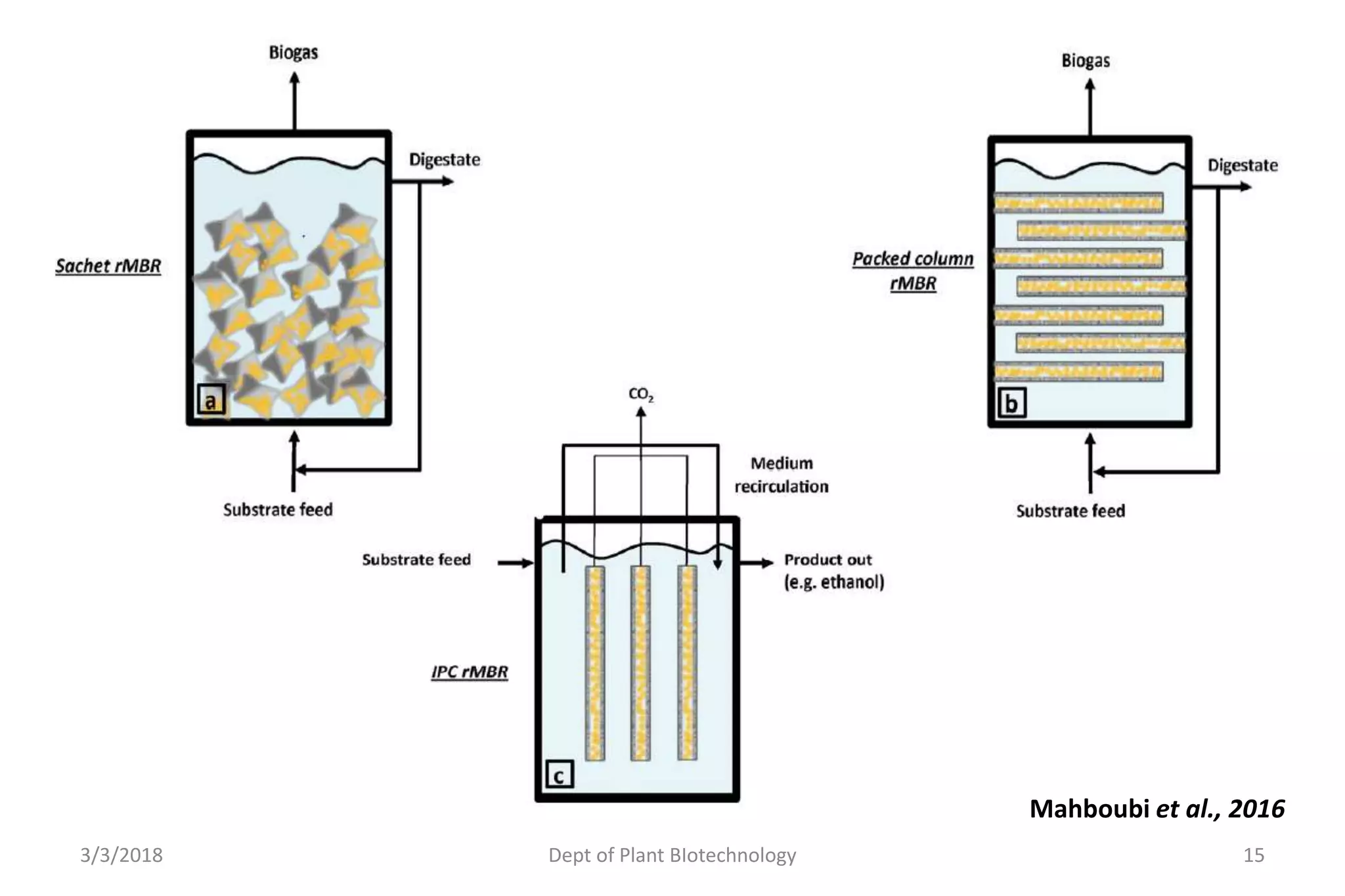

This document introduces reverse membrane bioreactors (rMBRs) as a new technology for biofuel production. rMBRs use diffusion instead of pressure to retain cells inside membrane modules placed in bioreactors. A case study is presented where an rMBR using a flat sheet membrane successfully facilitated simultaneous glucose and xylose consumption from synthetic media and pretreated wheat straw hydrolysate by yeast cells. The rMBR also enabled in situ detoxification of inhibitors. Testing confirmed the rMBR facilitated the required cell agglomeration for co-utilization of sugars and was effective for prolonged fermentation without contamination.