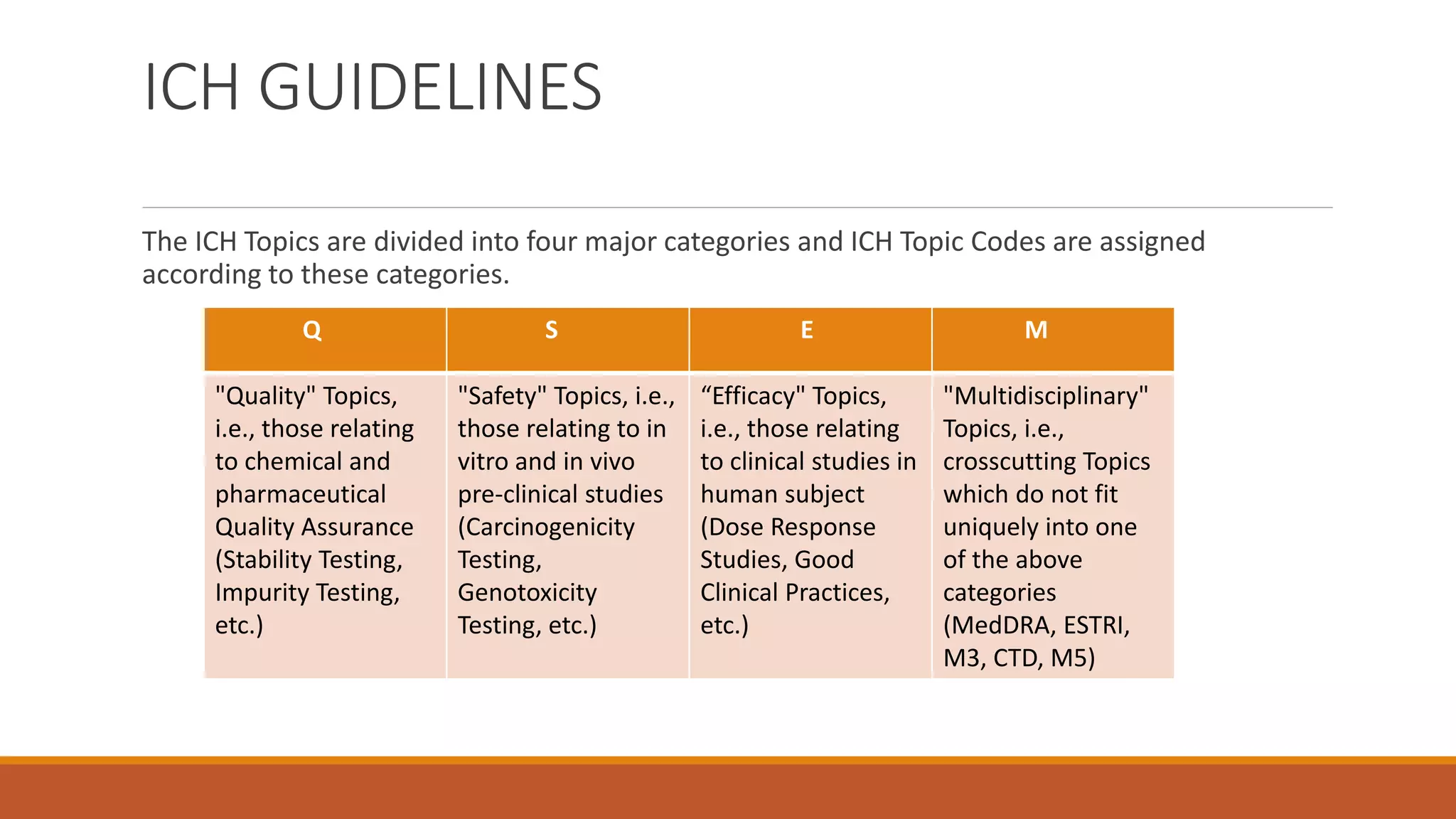

The document summarizes the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) guidelines. The ICH was established in 1990 and brings together regulatory authorities and the pharmaceutical industry from Europe, Japan, and the United States to discuss product registration and improve efficiency. The ICH has developed over 50 harmonized guidelines on quality, safety, efficacy, and other topics to eliminate duplication in the drug development and approval process. The guidelines cover areas like stability testing, analytical validation methods, impurities, biotechnological products, and good manufacturing practices.