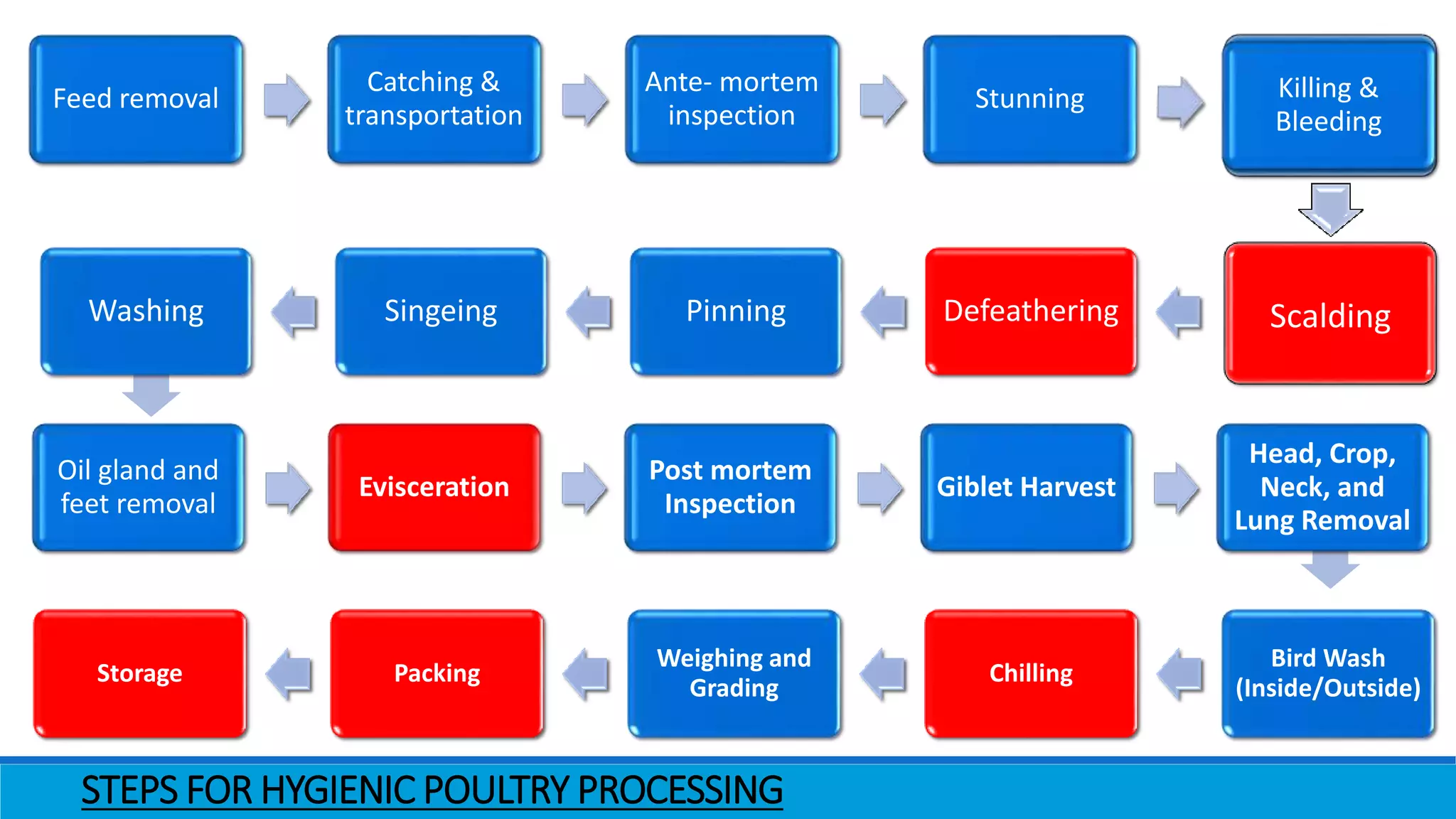

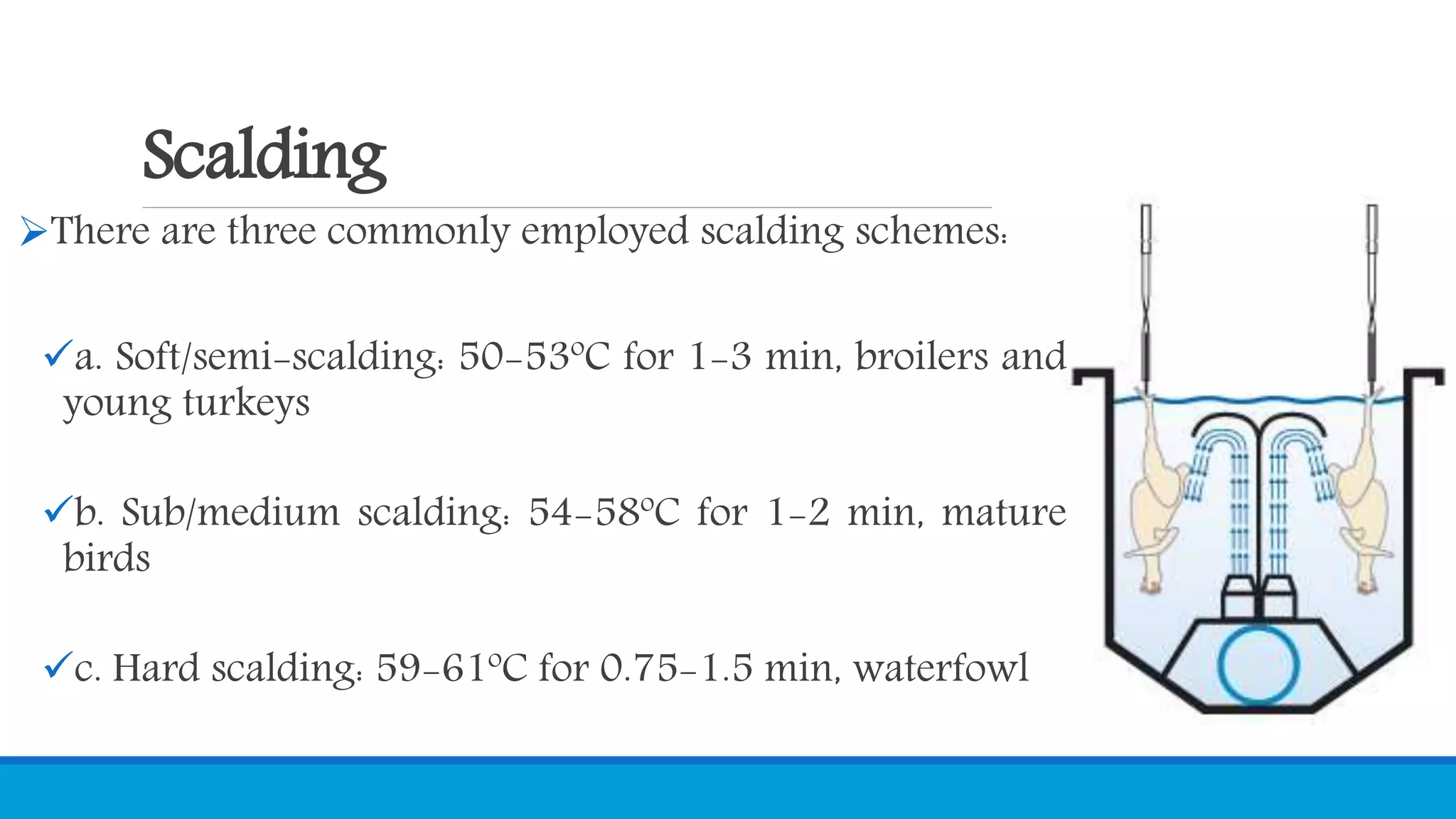

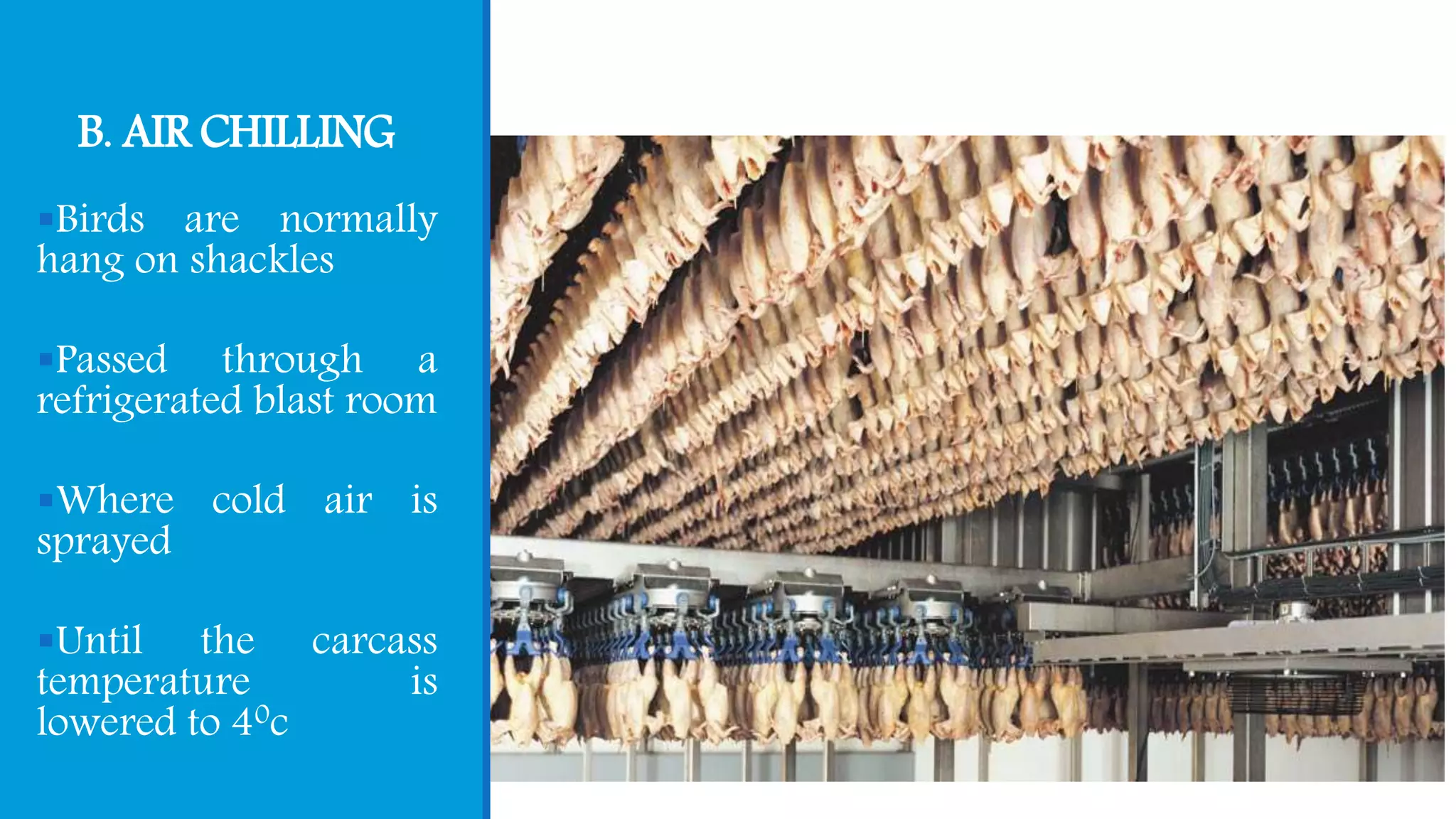

The document discusses hygienic practices for poultry processing. It begins by noting the importance of hygiene in processing to increase meat quality and shelf life. It then outlines the key steps in processing, including feed removal, catching and transporting live birds, ante-mortem inspection, stunning, bleeding, scalding, defeathering, evisceration, washing, chilling, grading and packing. Maintaining hygiene throughout processing helps prevent the spread of disease and ensures meat is fit for human consumption.