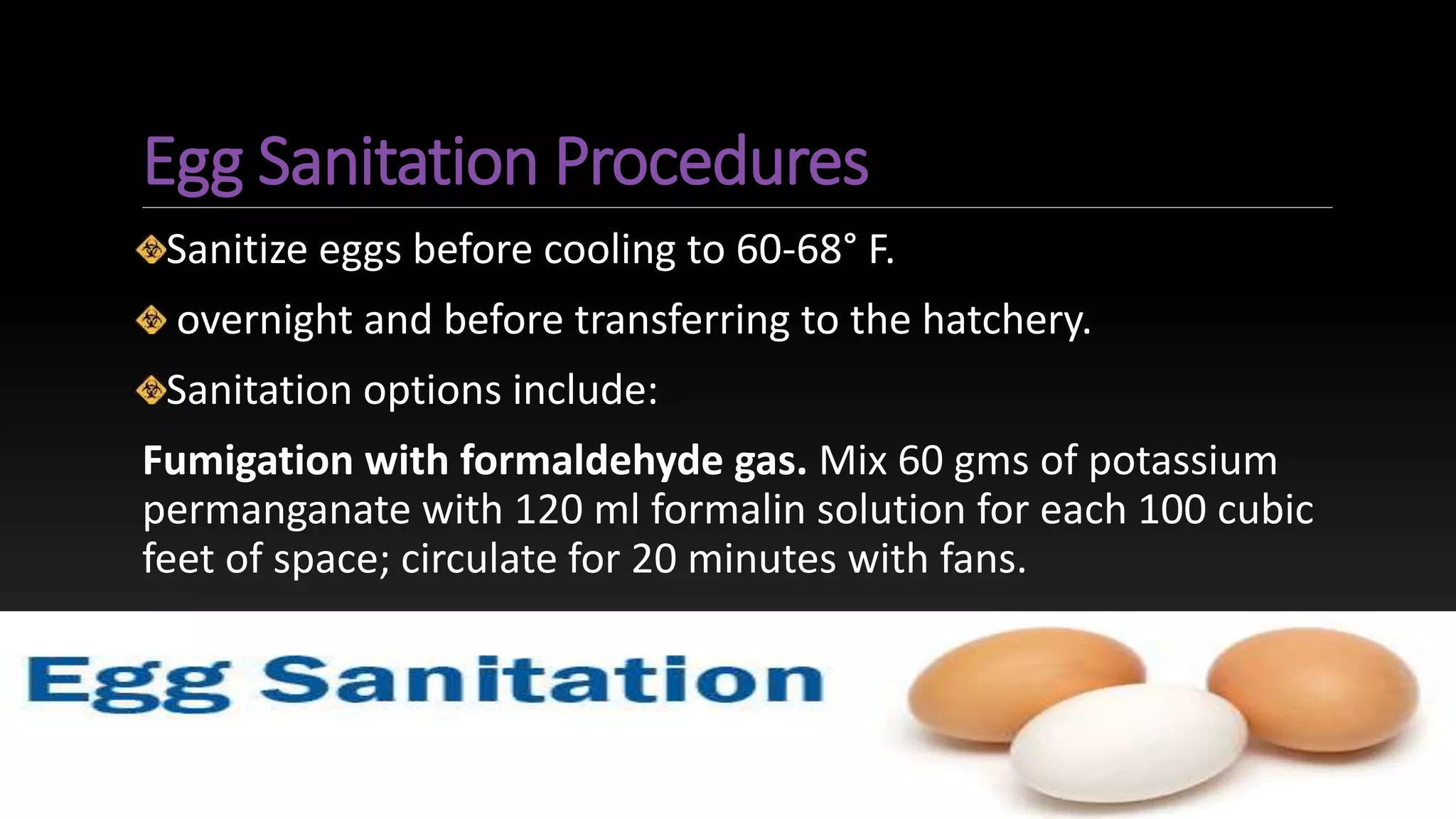

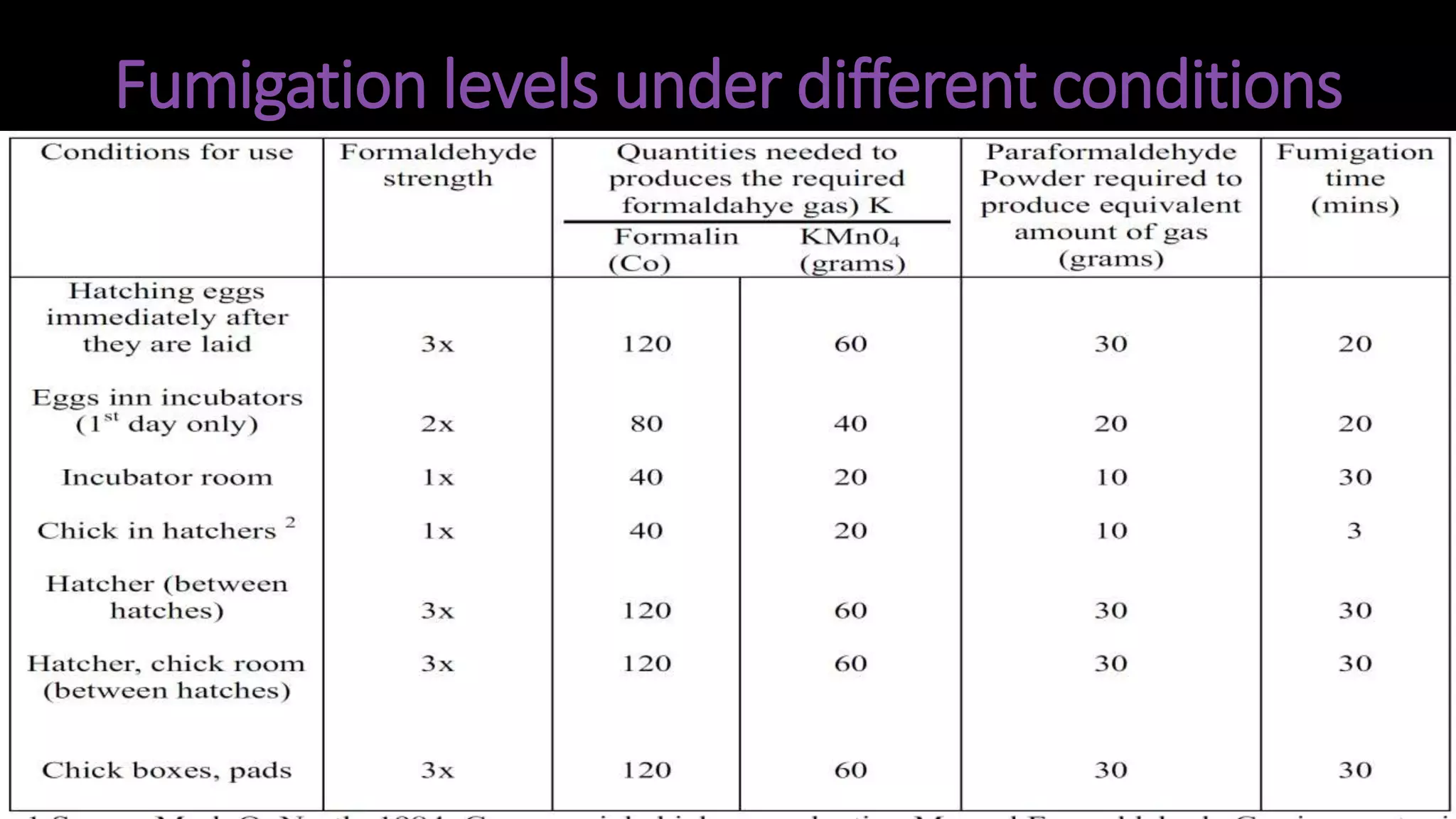

This document discusses biosecurity practices for hatcheries. It outlines four types of biosecurity: conceptual, structural, operational, and functional. The three major components of biosecurity are isolation, traffic control, and sanitation. It provides detailed guidelines for handling hatching eggs, vehicles/equipment, pests, facilities, employees/visitors, and sanitation programs. Regular cleaning and disinfection of equipment, rooms, and surfaces is emphasized along with employee training and documentation to maintain disease-free chicks through effective biosecurity measures.