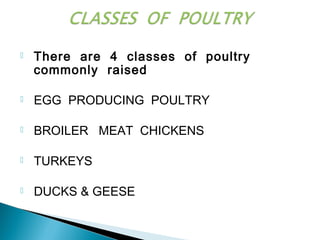

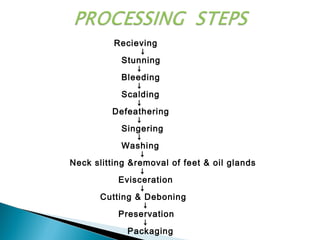

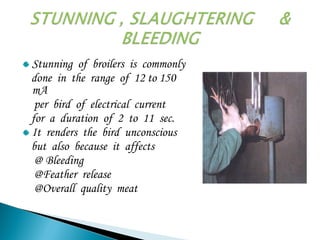

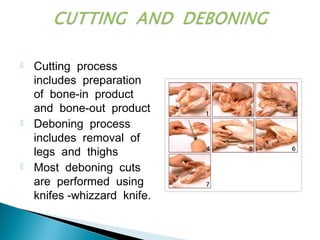

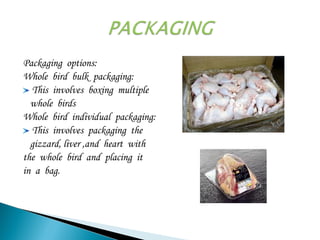

This document discusses the processing of chicken and broilers for meat. It begins by defining poultry and identifying the four main classes raised - egg producing, broilers, turkeys, and ducks/geese. It then outlines the key steps in broiler processing from receiving the live birds to packaging the finished product. These steps include stunning, bleeding, scalding, defeathering, evisceration, cutting/deboning, and preservation methods like refrigeration, smoking, and packaging. Preservation methods help extend shelf life and ensure food safety.