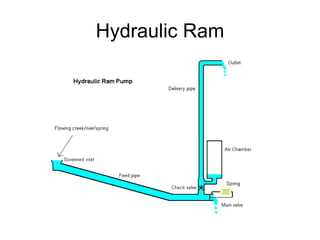

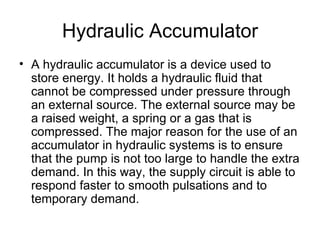

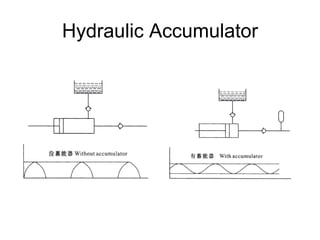

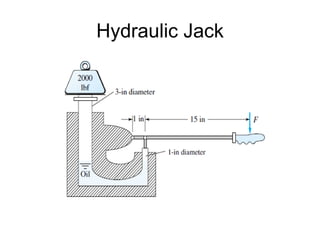

This document outlines various hydraulic devices: hydraulic couplings transfer power between shafts using oil; torque converters multiply torque using guide vanes; hydraulic rams use water hammer to pump water to higher elevations; accumulators store hydraulic fluid under pressure to smooth demand; and jacks lift heavy objects using hydraulic force.