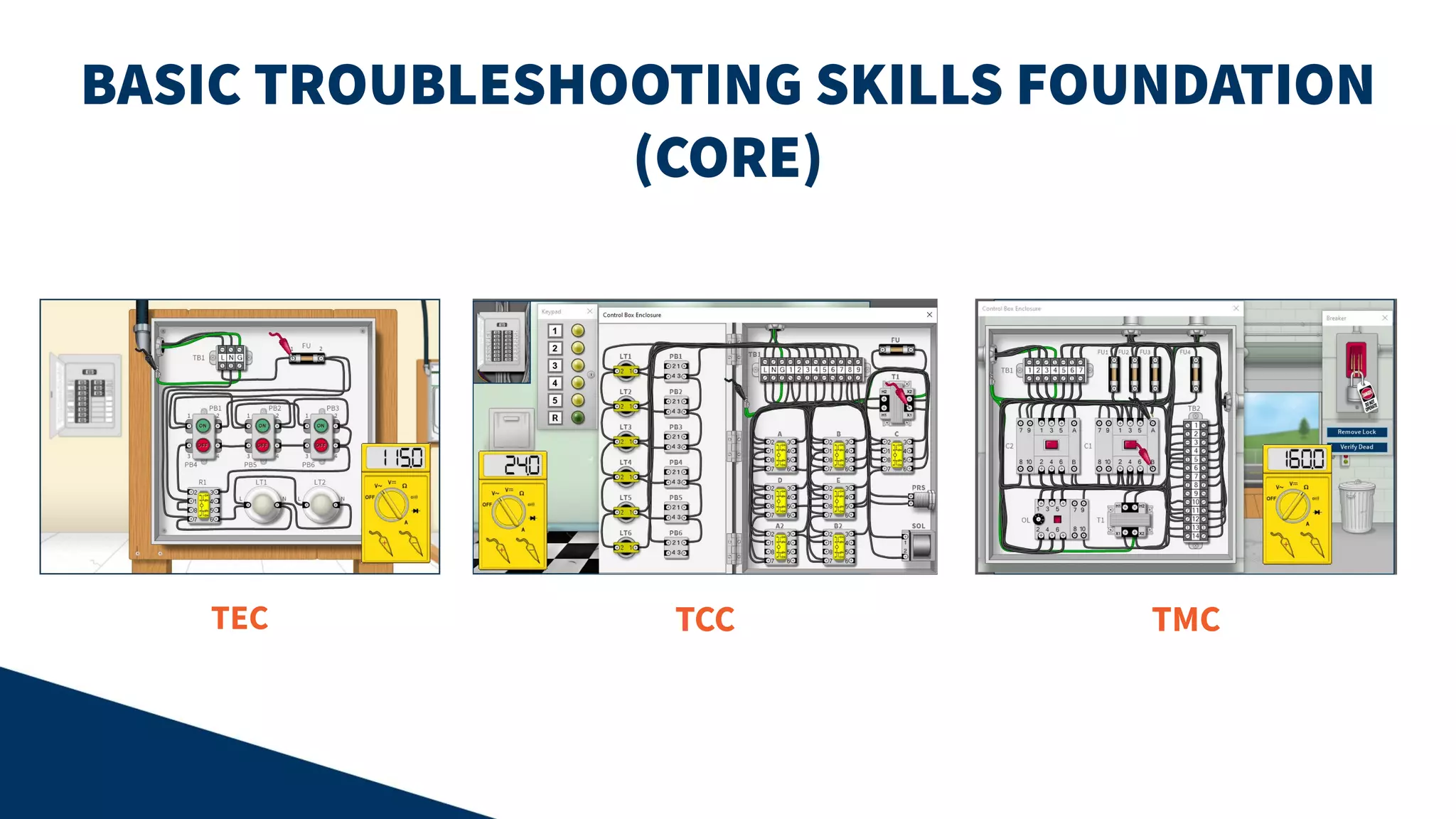

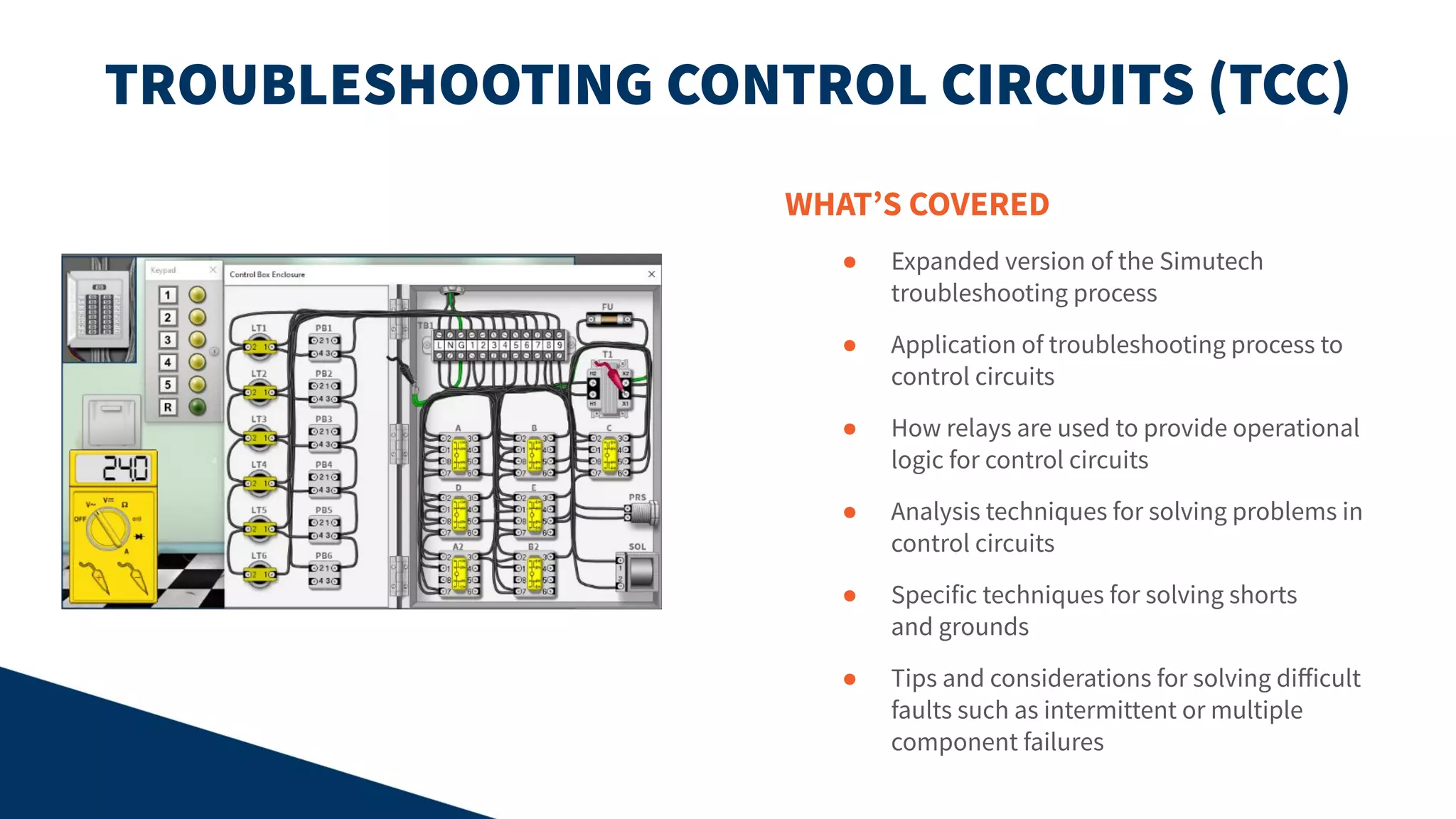

This document describes the Simutech Training System, which provides troubleshooting simulations for various electrical, motor, control, sensor, and PLC circuits. It is structured in 5 levels to build competency in industrial troubleshooting. Level 1 covers basic skills, level 2 adds intermediate faults, level 3 introduces PLCs and advanced systems, level 4 requires completing all extra and genius faults, and level 5 involves refining skills with a recommended schedule. The system uses learning labs and simulations at basic through genius levels of difficulty to train troubleshooting skills for electromechanical and automated industrial control systems.