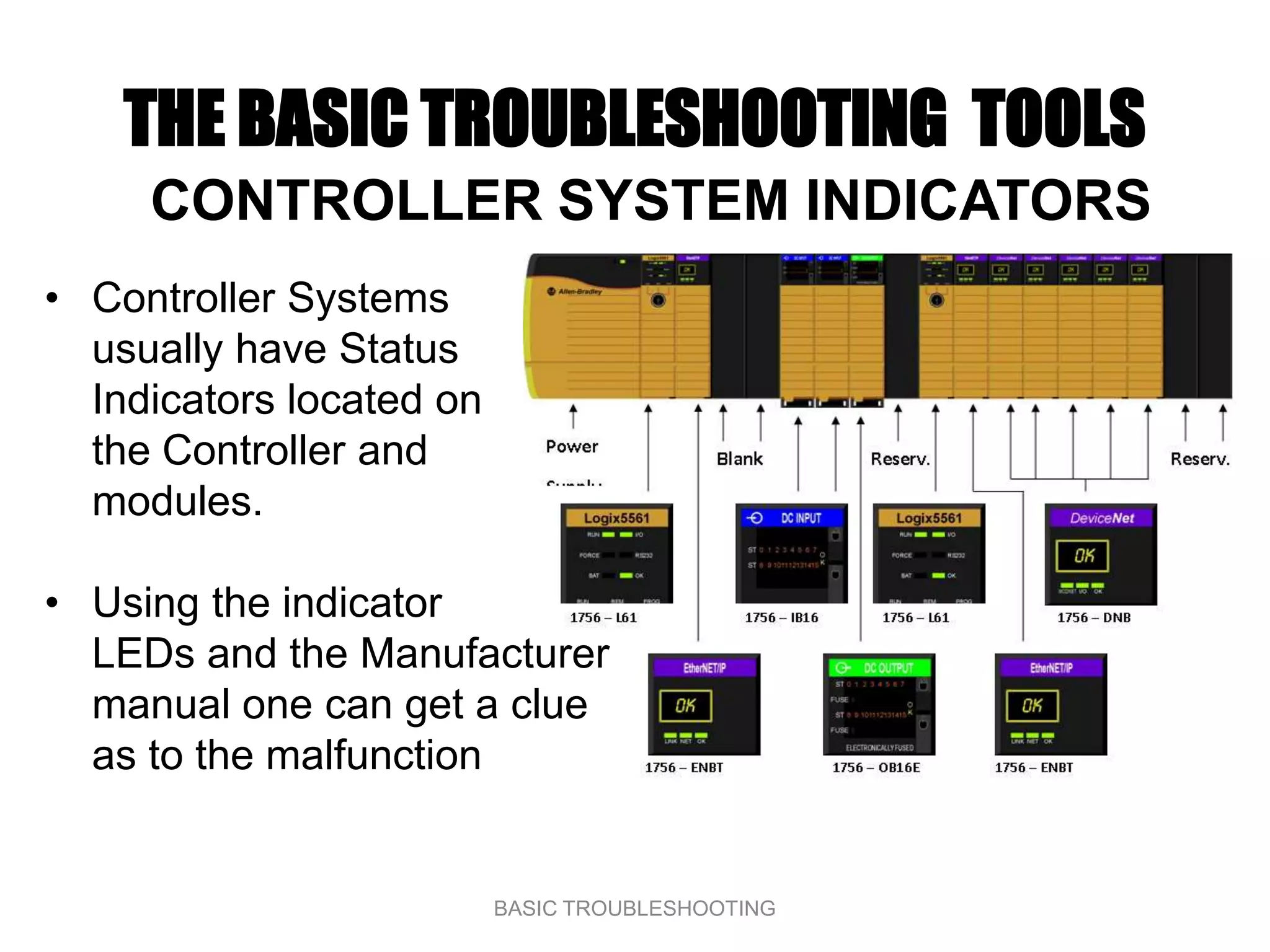

This document outlines a basic troubleshooting course that teaches a functional search strategy using sensory input, filtering, action, and documentation to systematically identify the root cause of malfunctions in industrial processes, with the goal of improving troubleshooting effectiveness and reducing downtime.