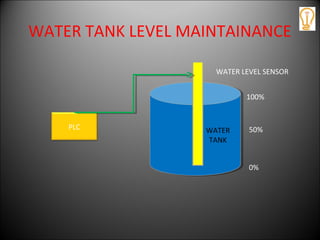

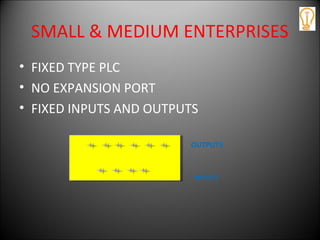

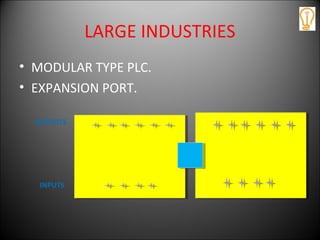

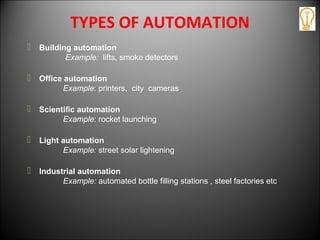

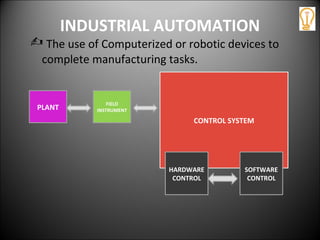

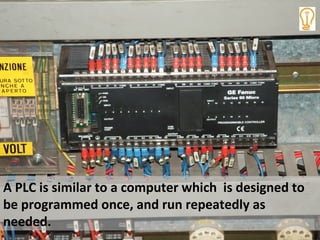

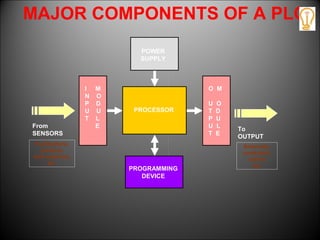

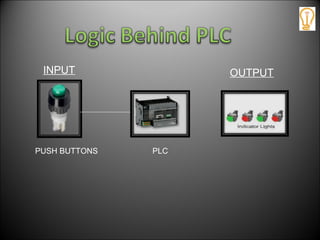

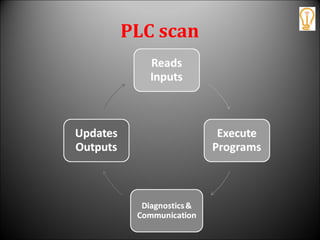

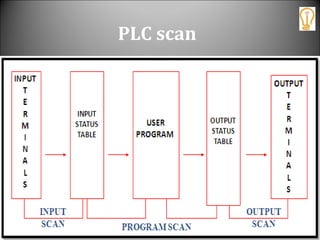

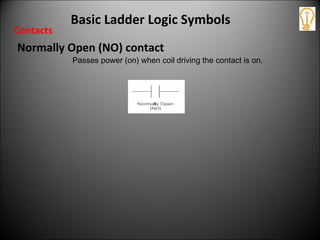

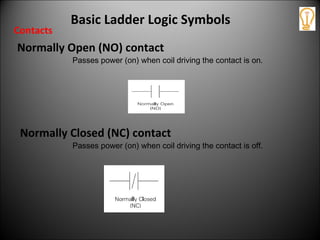

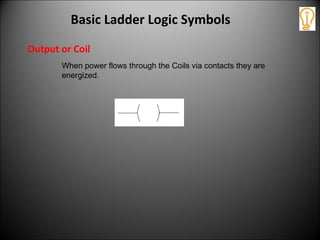

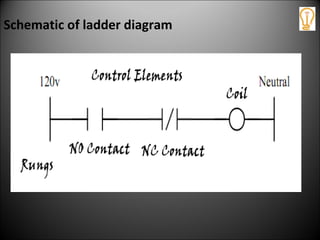

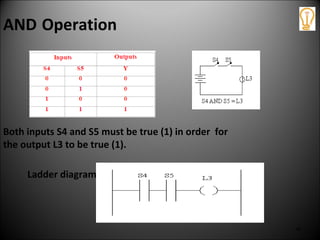

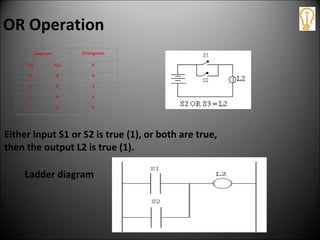

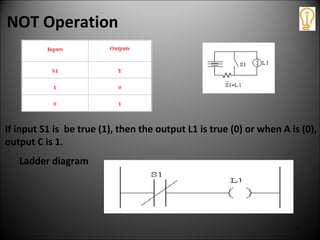

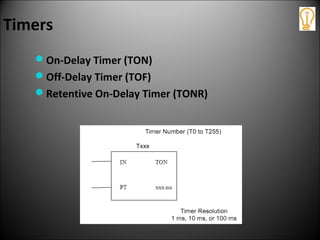

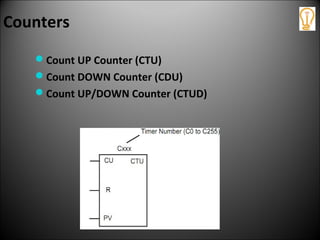

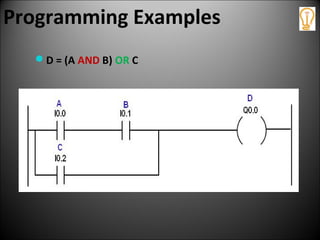

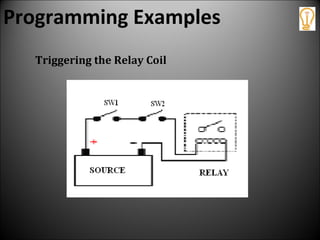

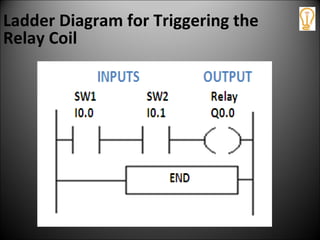

This document presents an introduction to Programmable Logic Controllers (PLCs) and their programming using ladder logic, emphasizing the automation of processes with minimal human intervention. It outlines the advantages of automation, types of PLCs for different industries, and the components that make up a PLC system. Additionally, it explains basic ladder logic programming, including common symbols and programming functions like timers and counters.