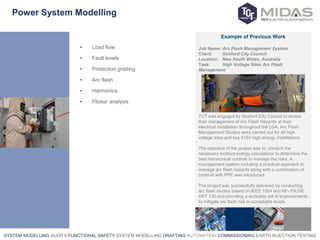

TCT Electrical Engineering provides electrical engineering solutions such as power system engineering, automation and control, project management, occupational health and safety management systems, and earth resistance and injection testing. It has expertise in areas including power systems engineering and design, electrical procedures and compliance, power system modelling, electrical audits and reviews, electrical project management, electrical drafting, automation and control engineering, and OH&S management. TCT Electrical Engineering has offices in New South Wales, Western Australia and Victoria and works on projects across industries such as energy, mining, oil and gas, building, and commercial.