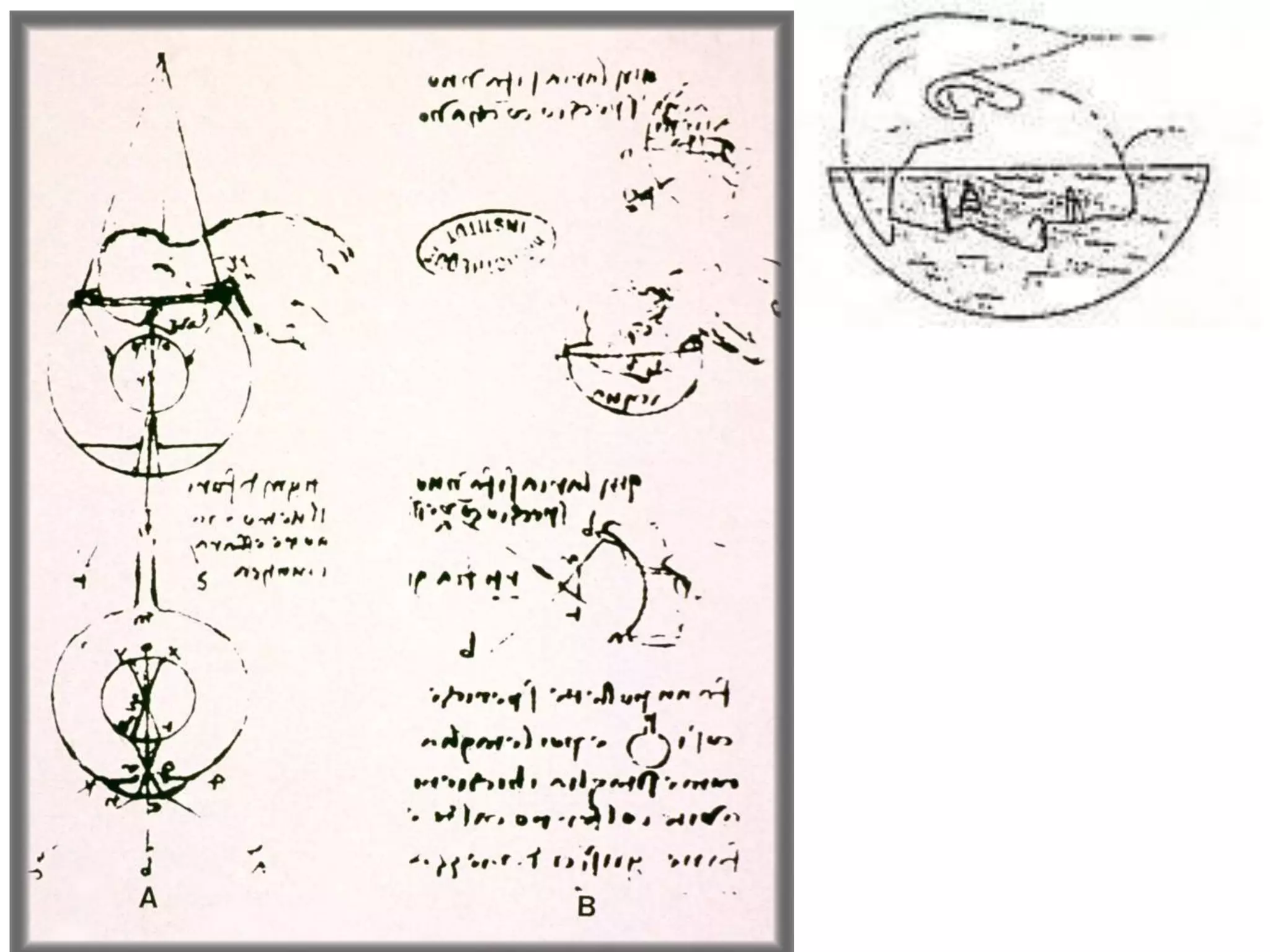

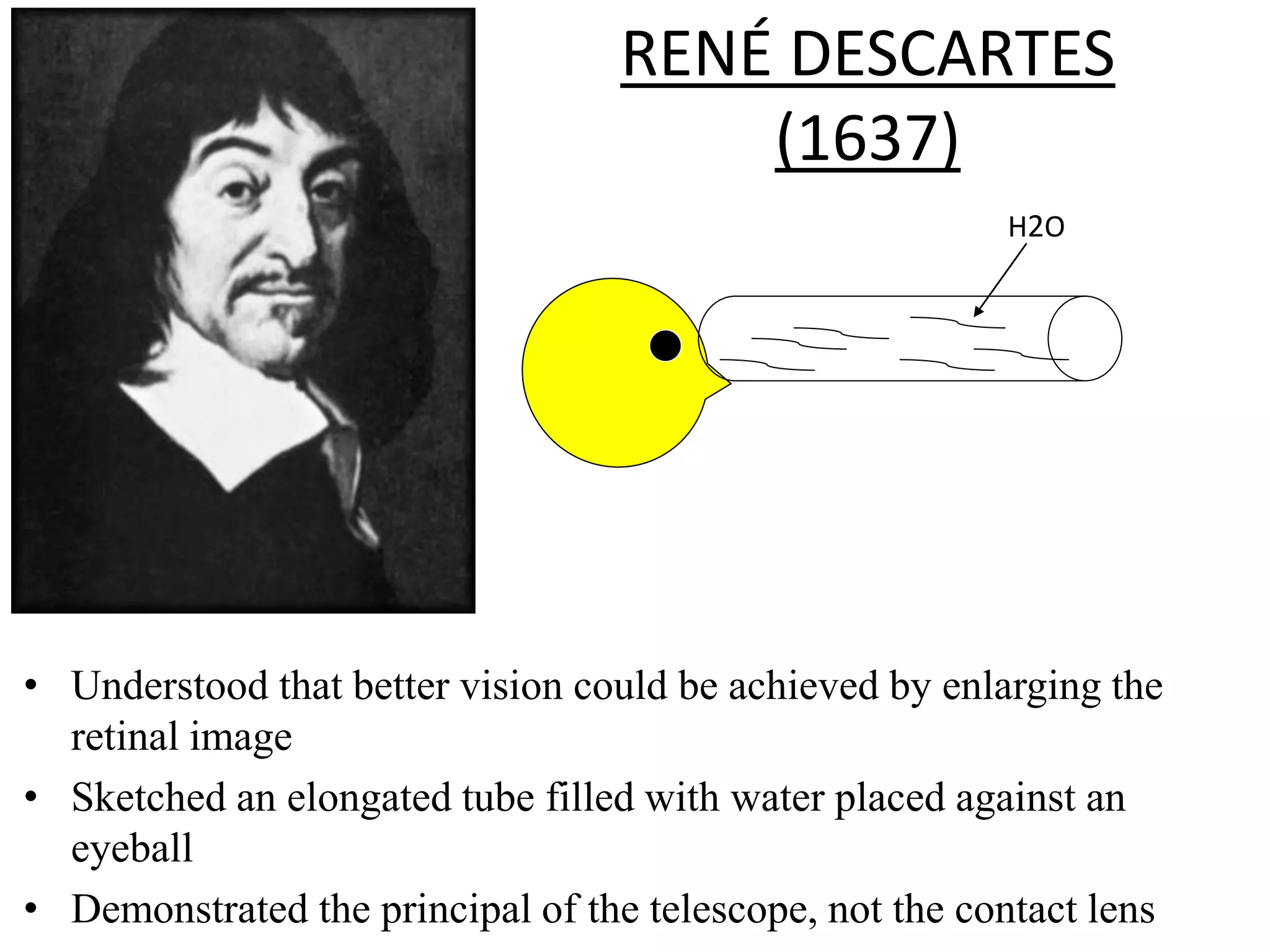

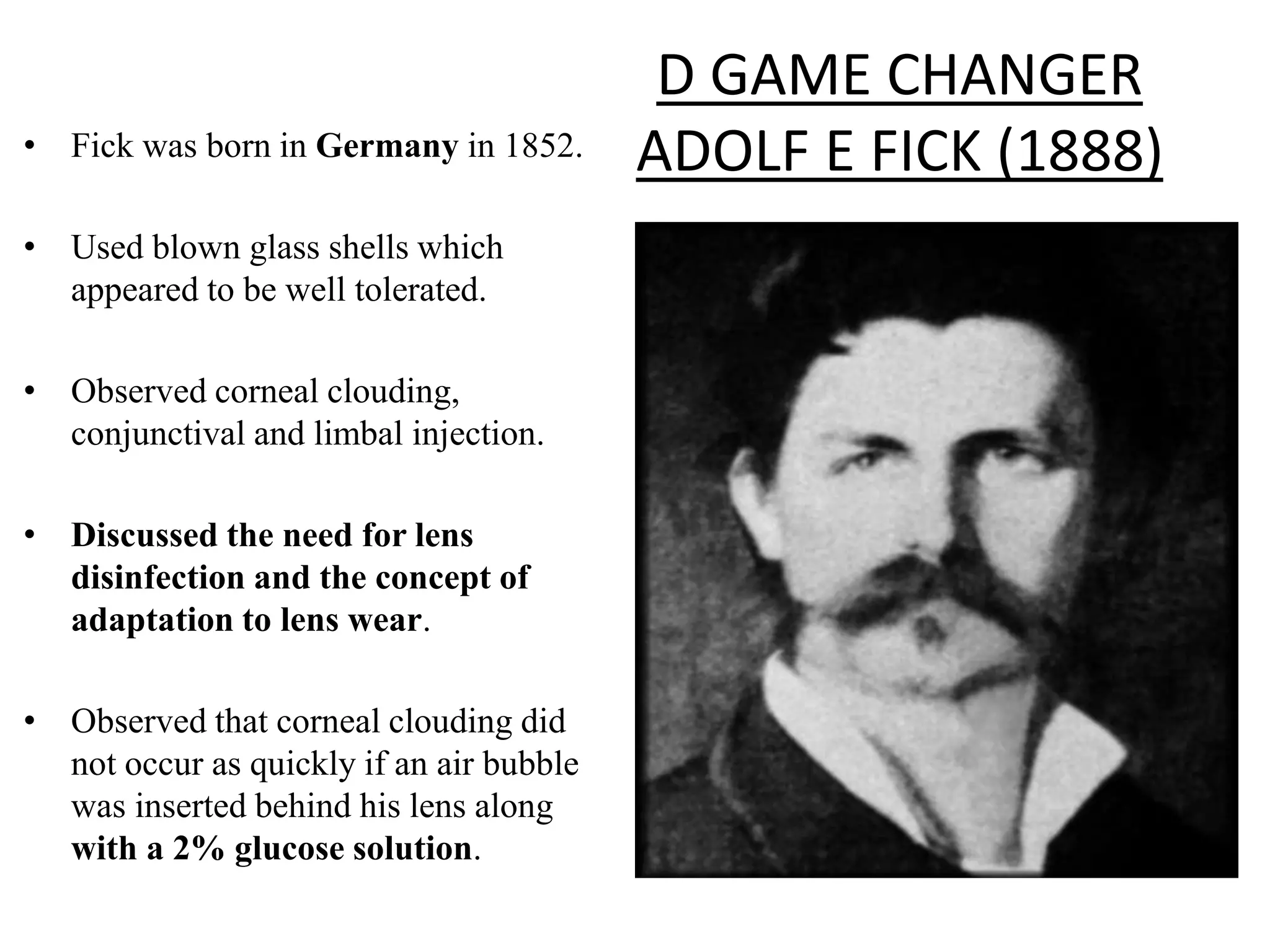

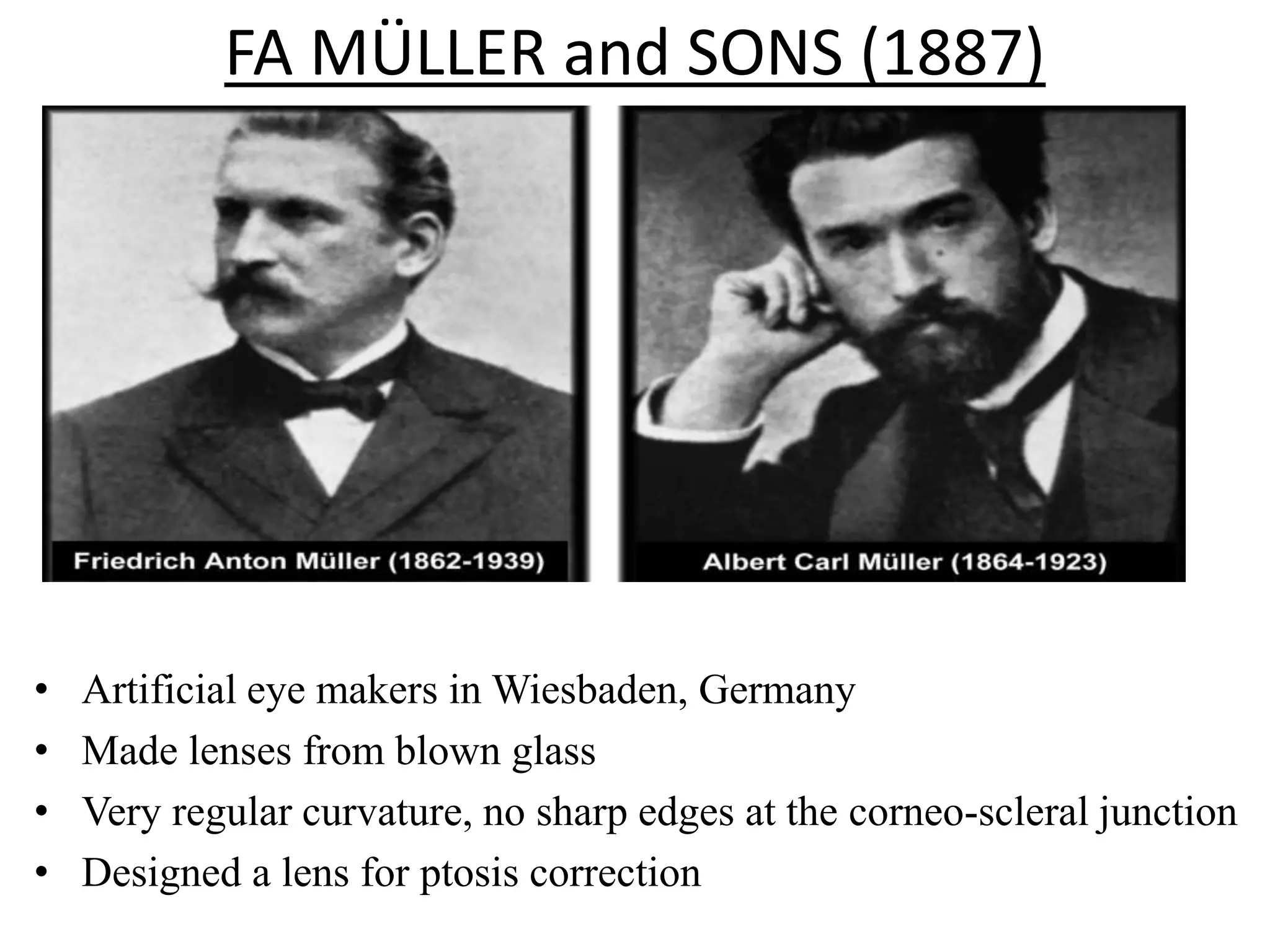

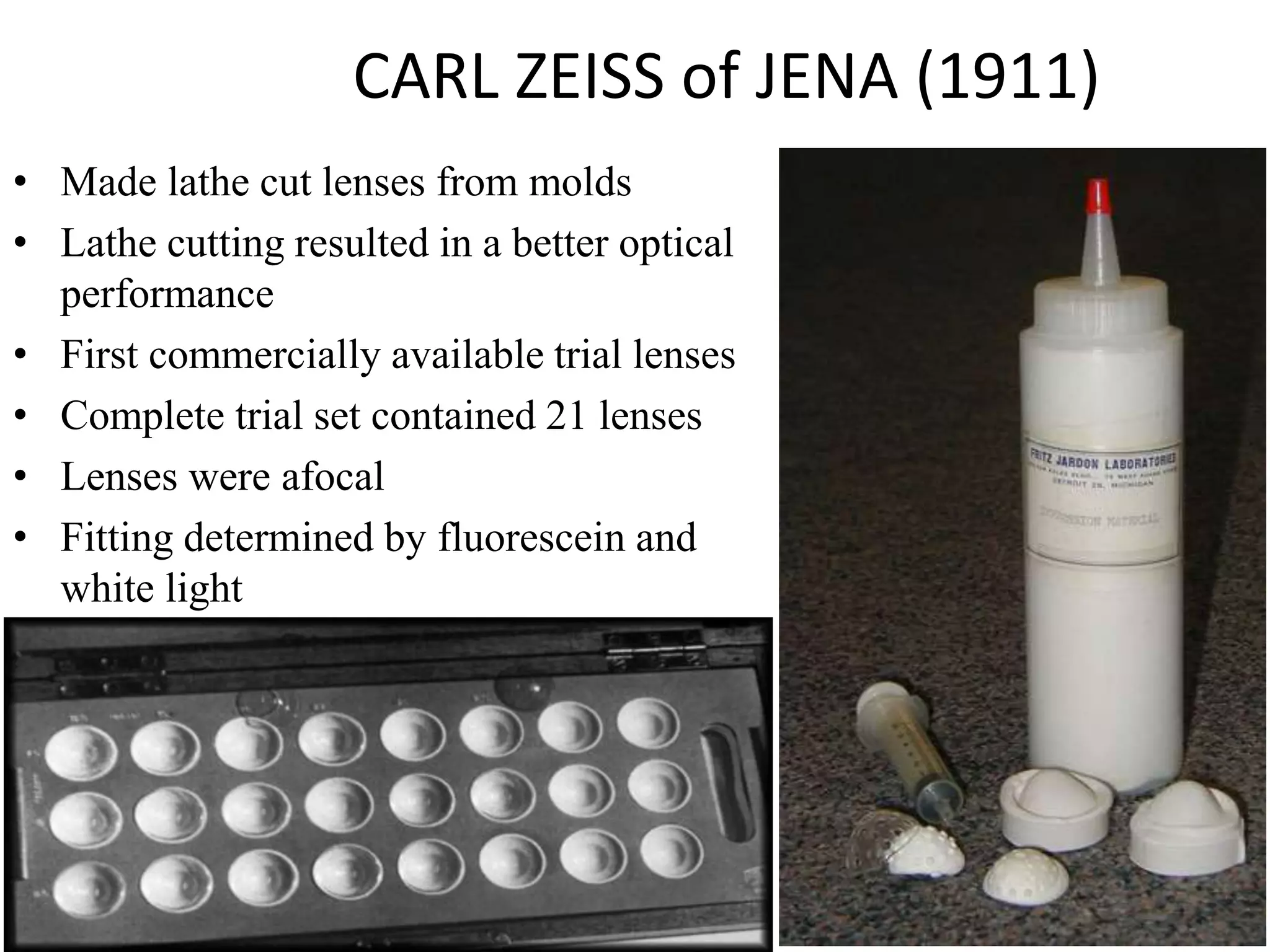

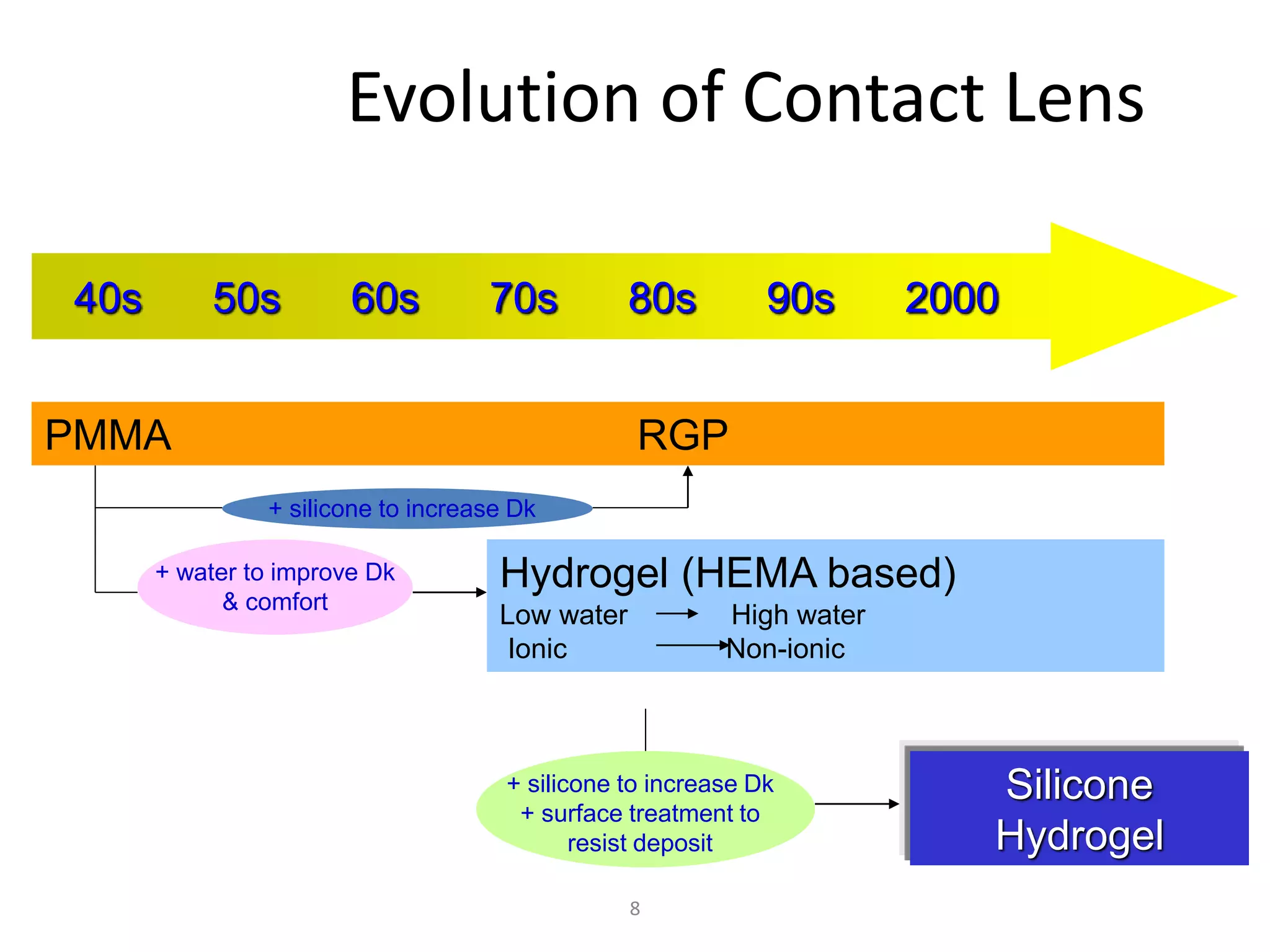

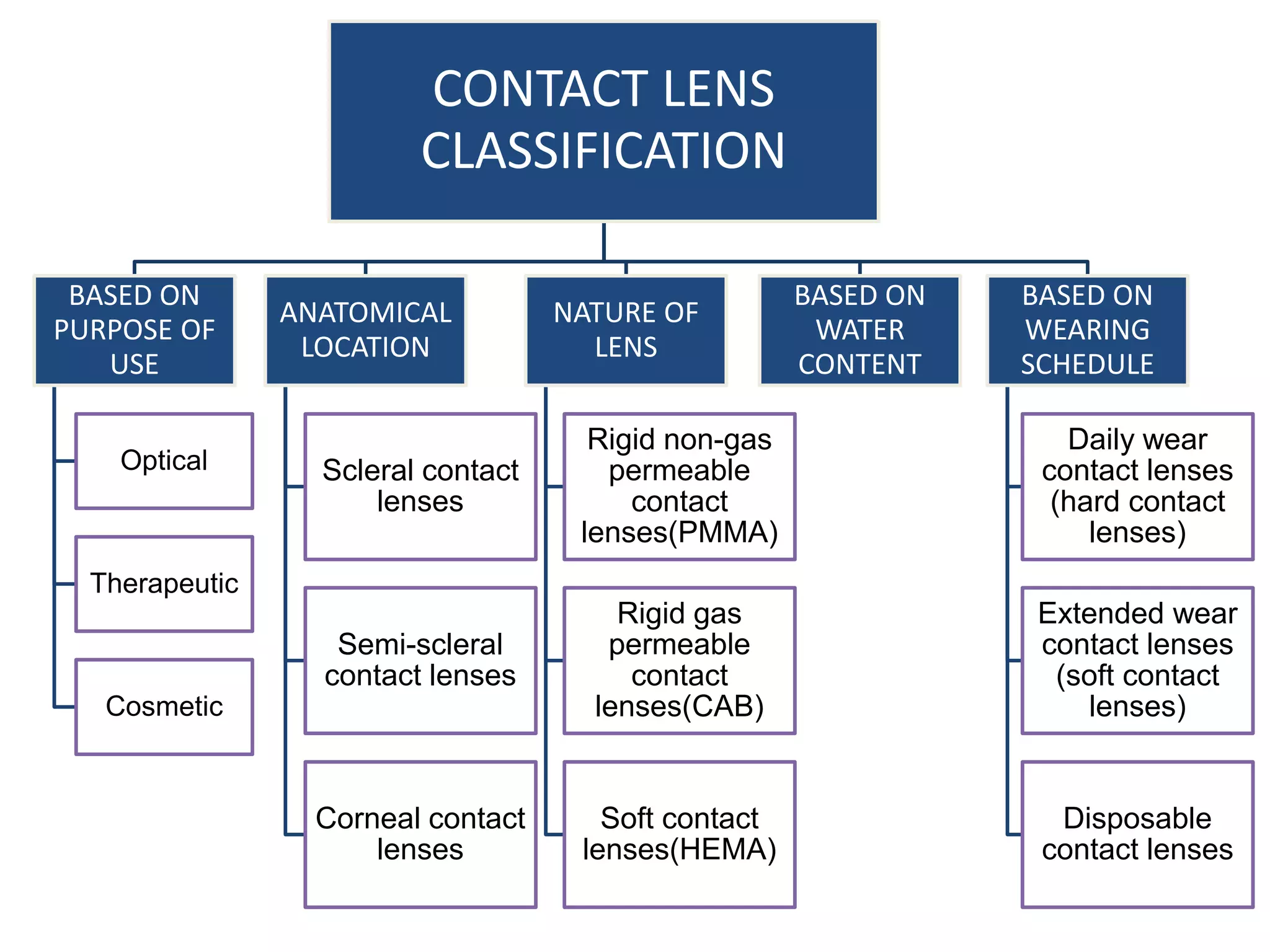

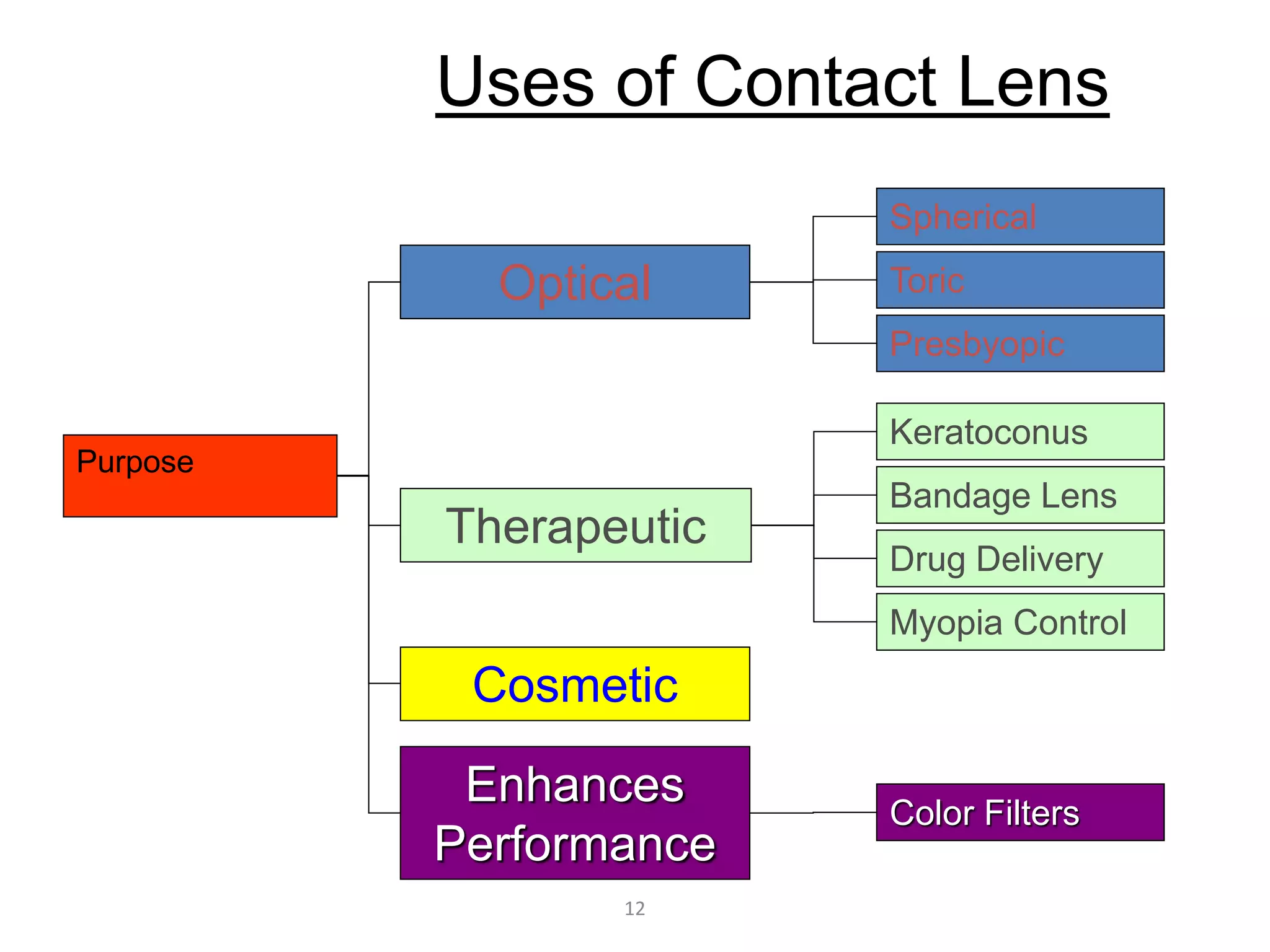

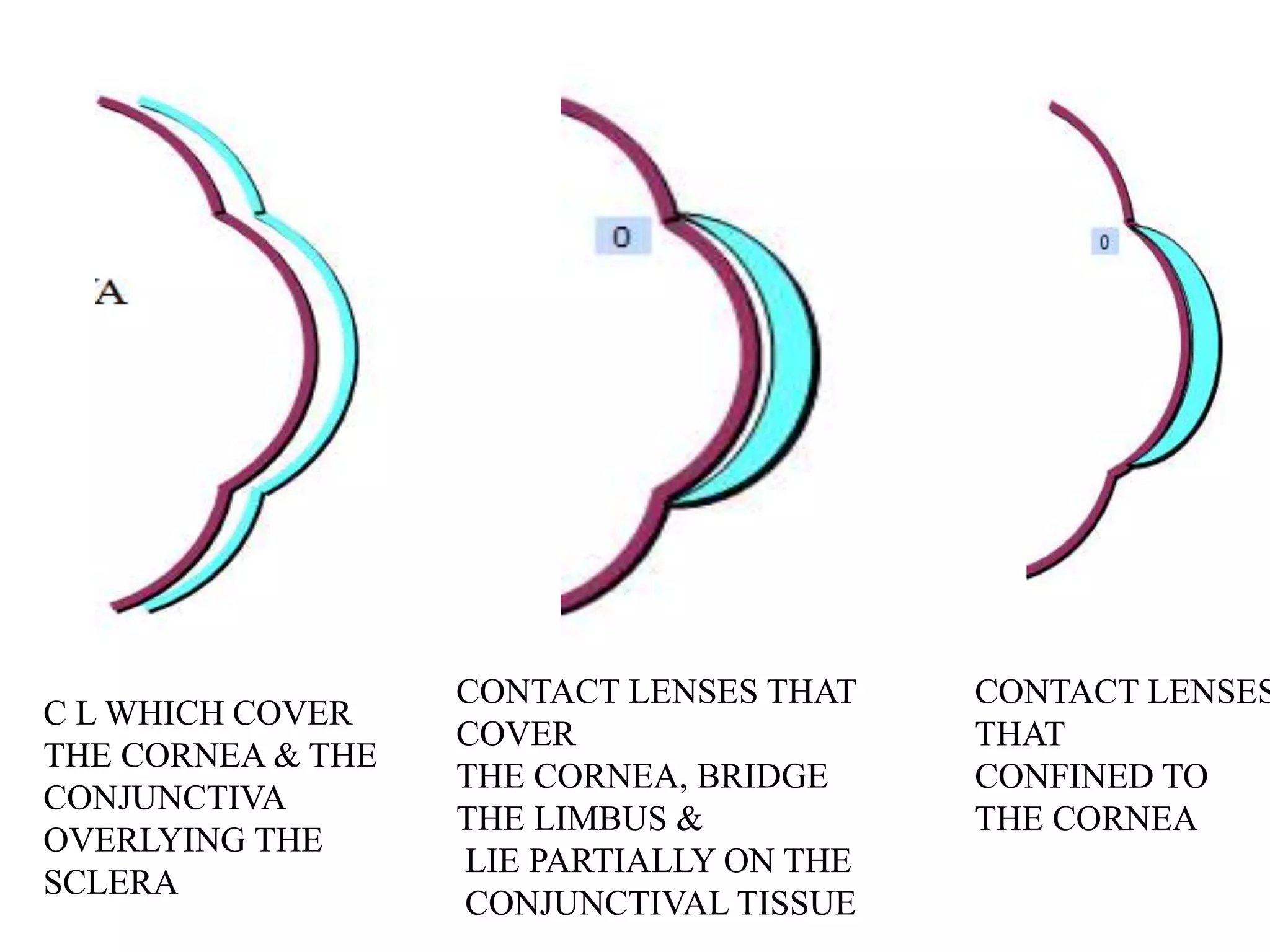

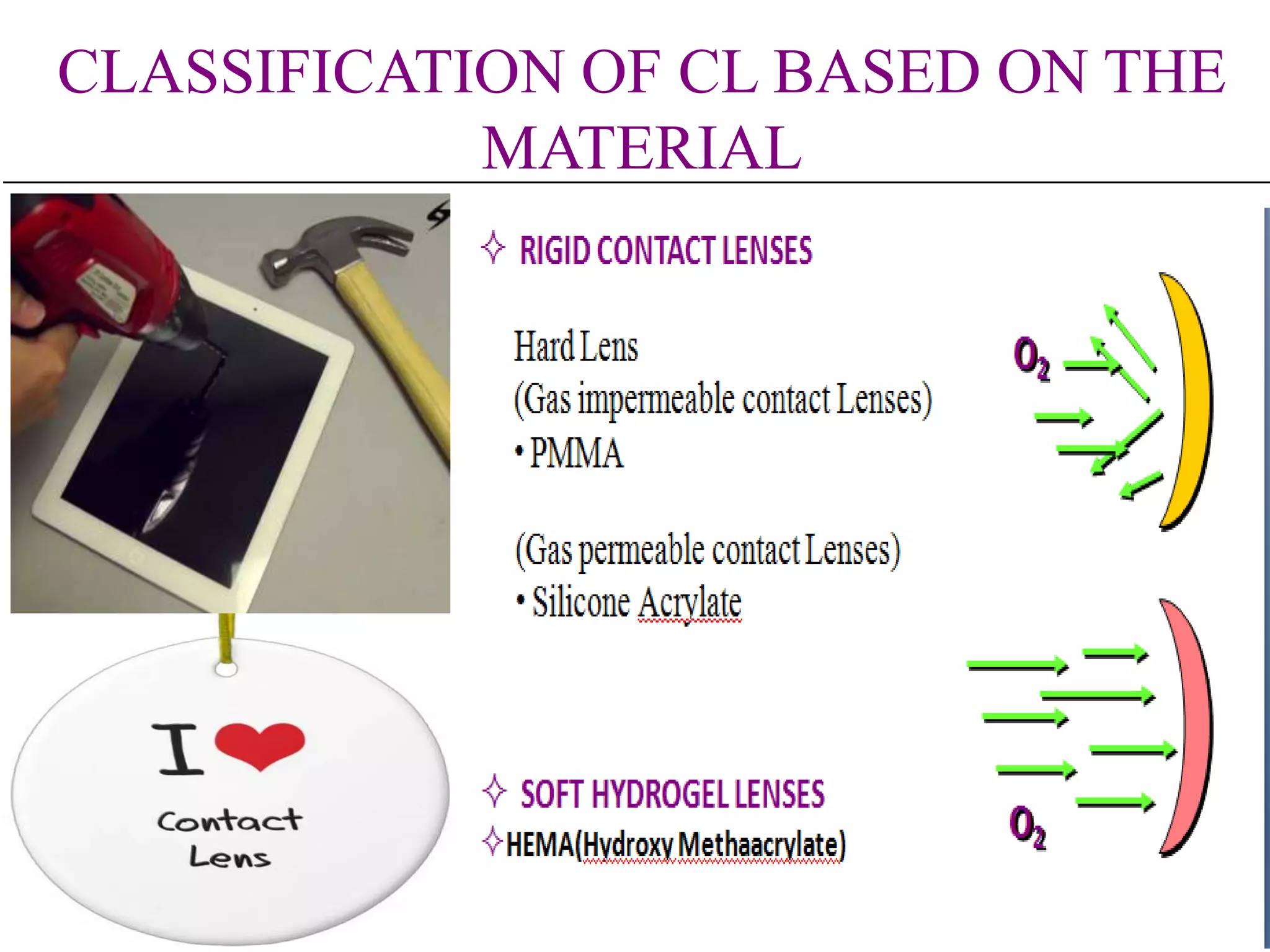

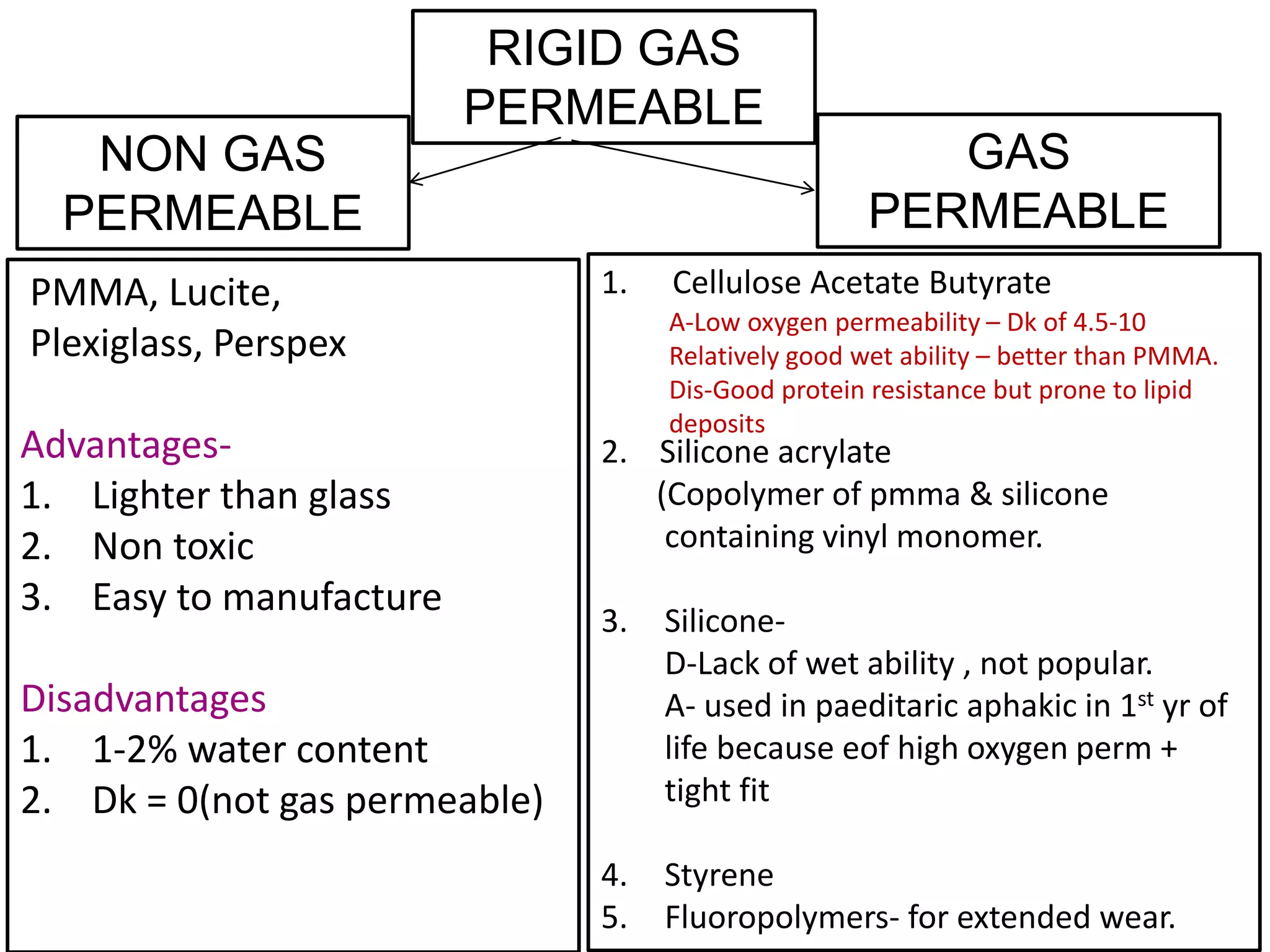

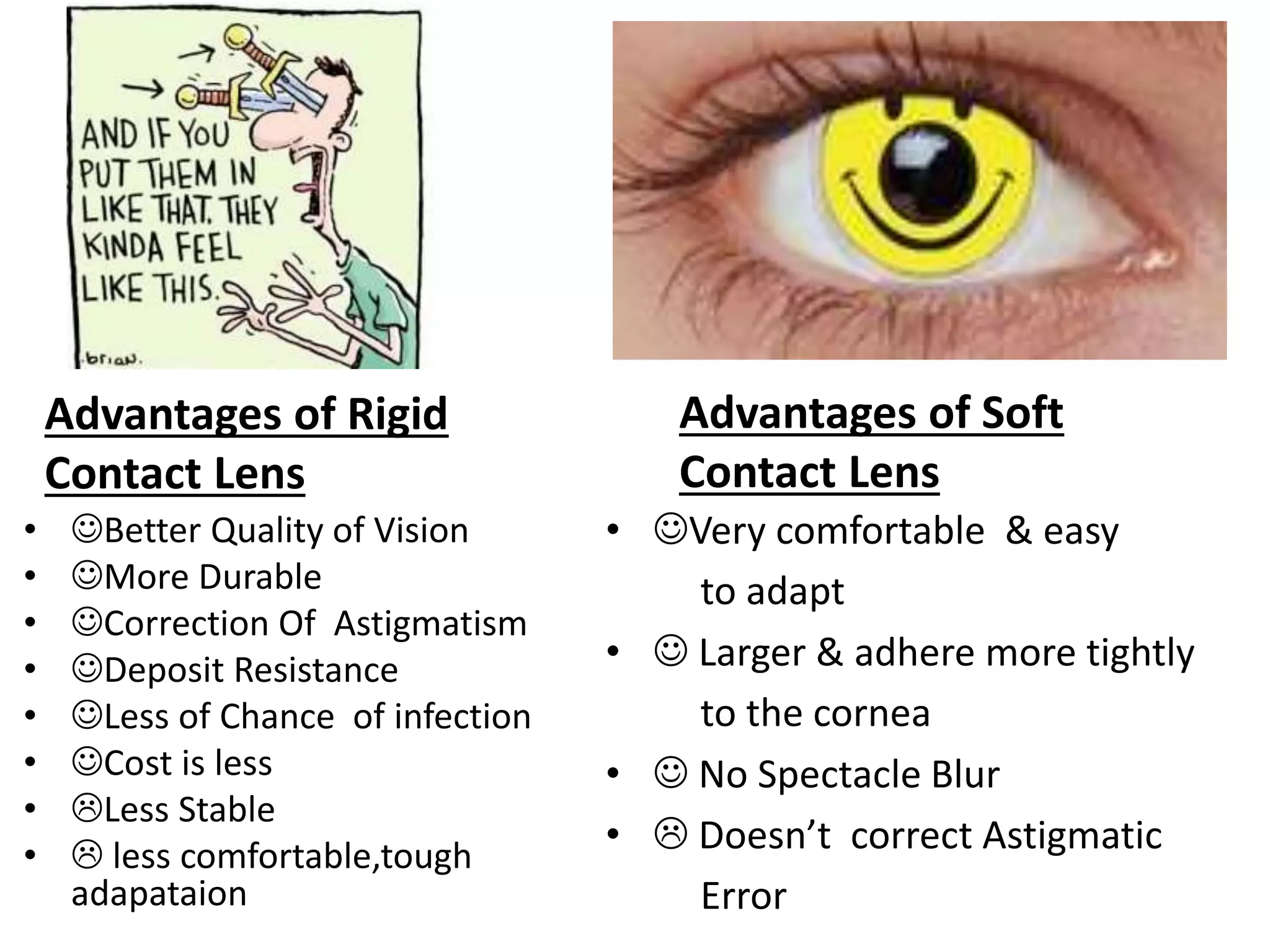

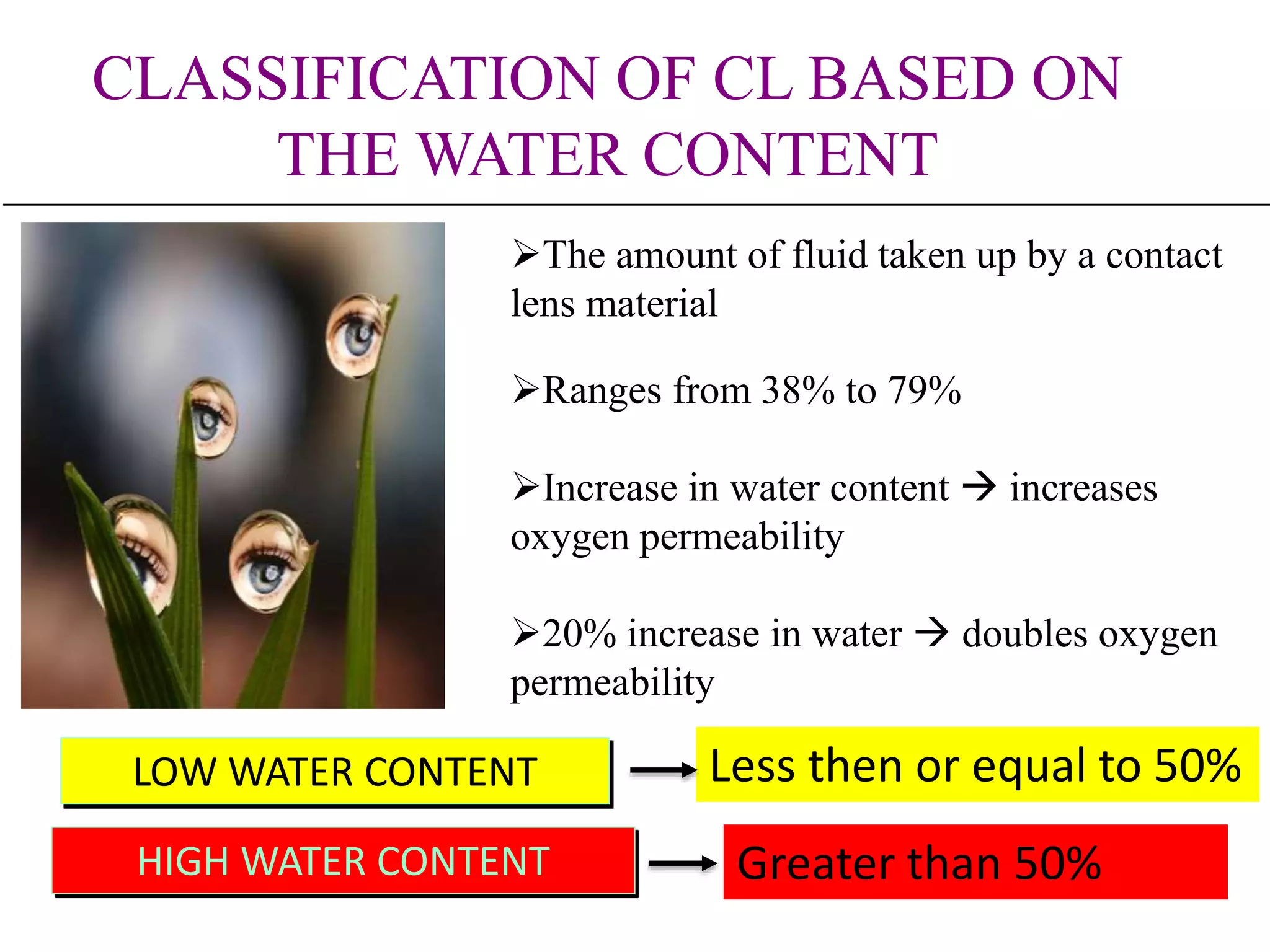

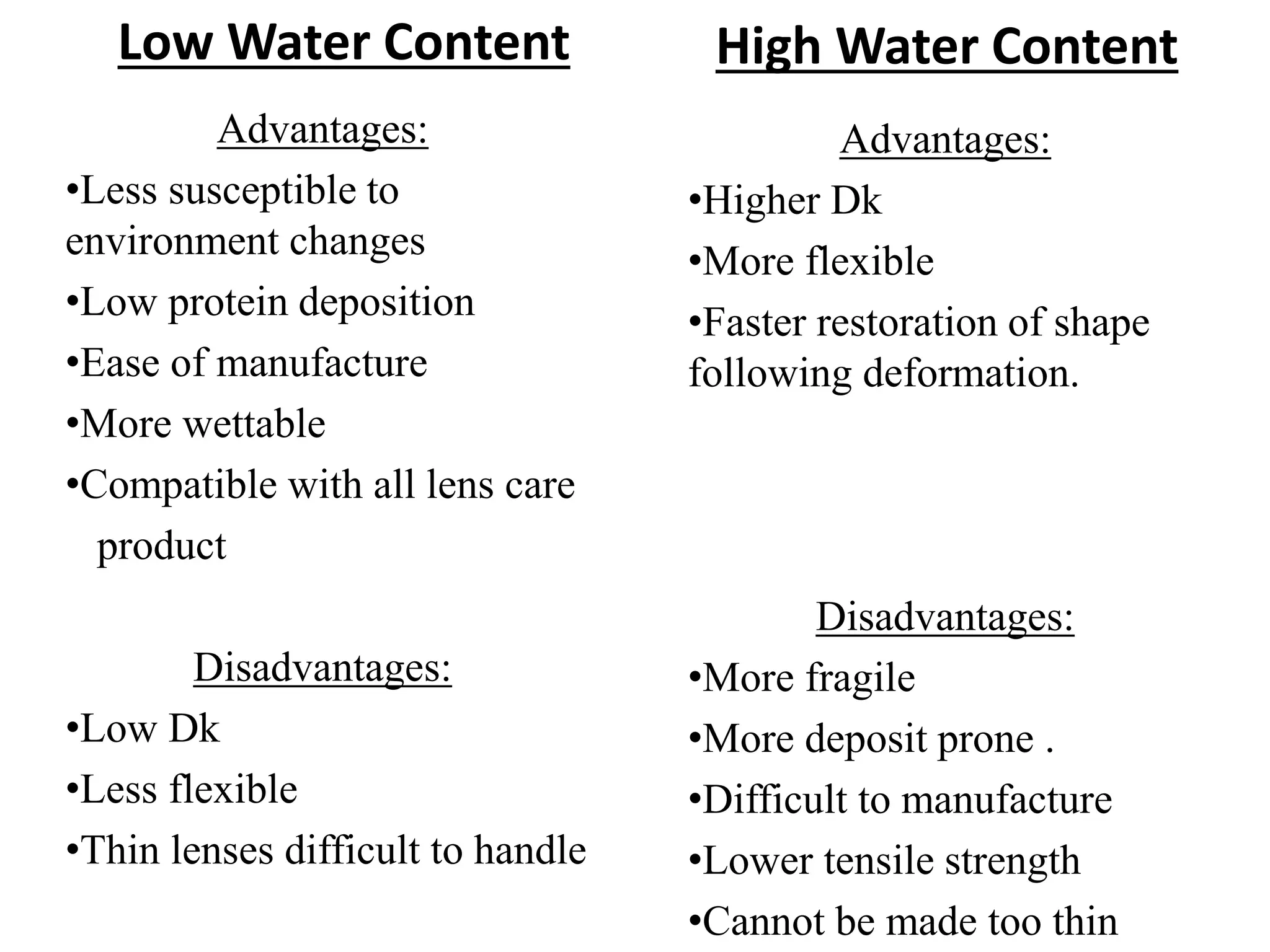

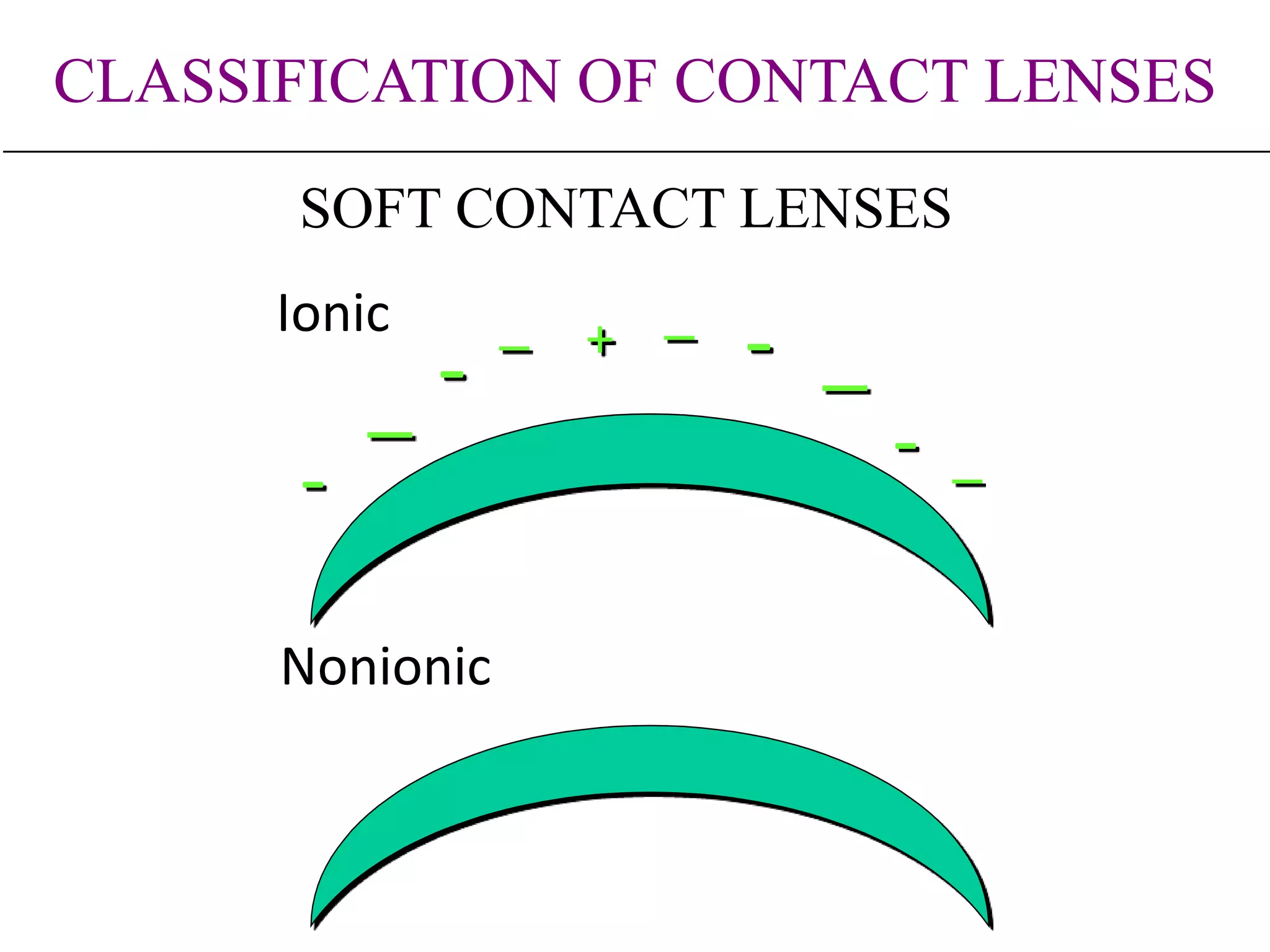

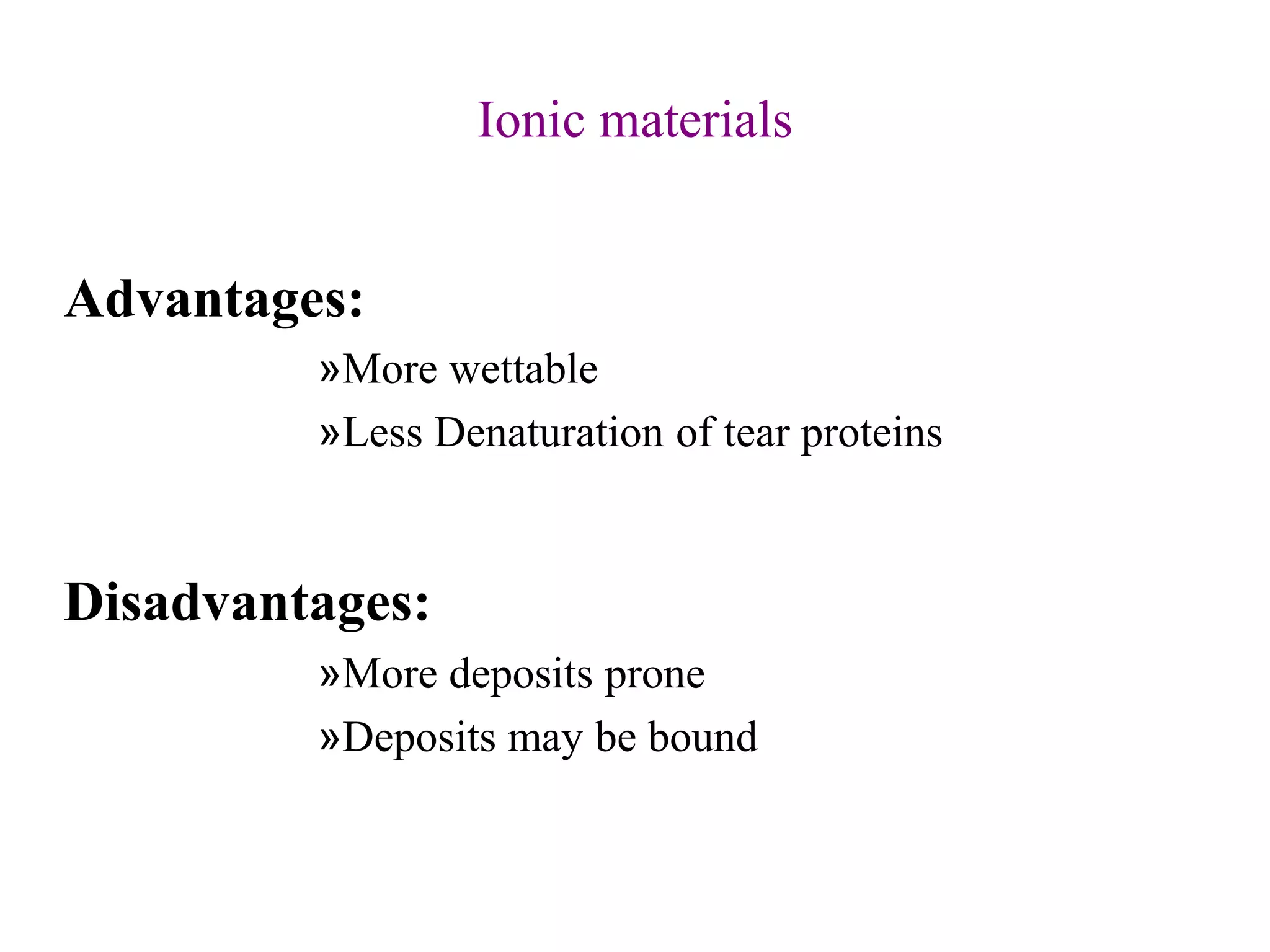

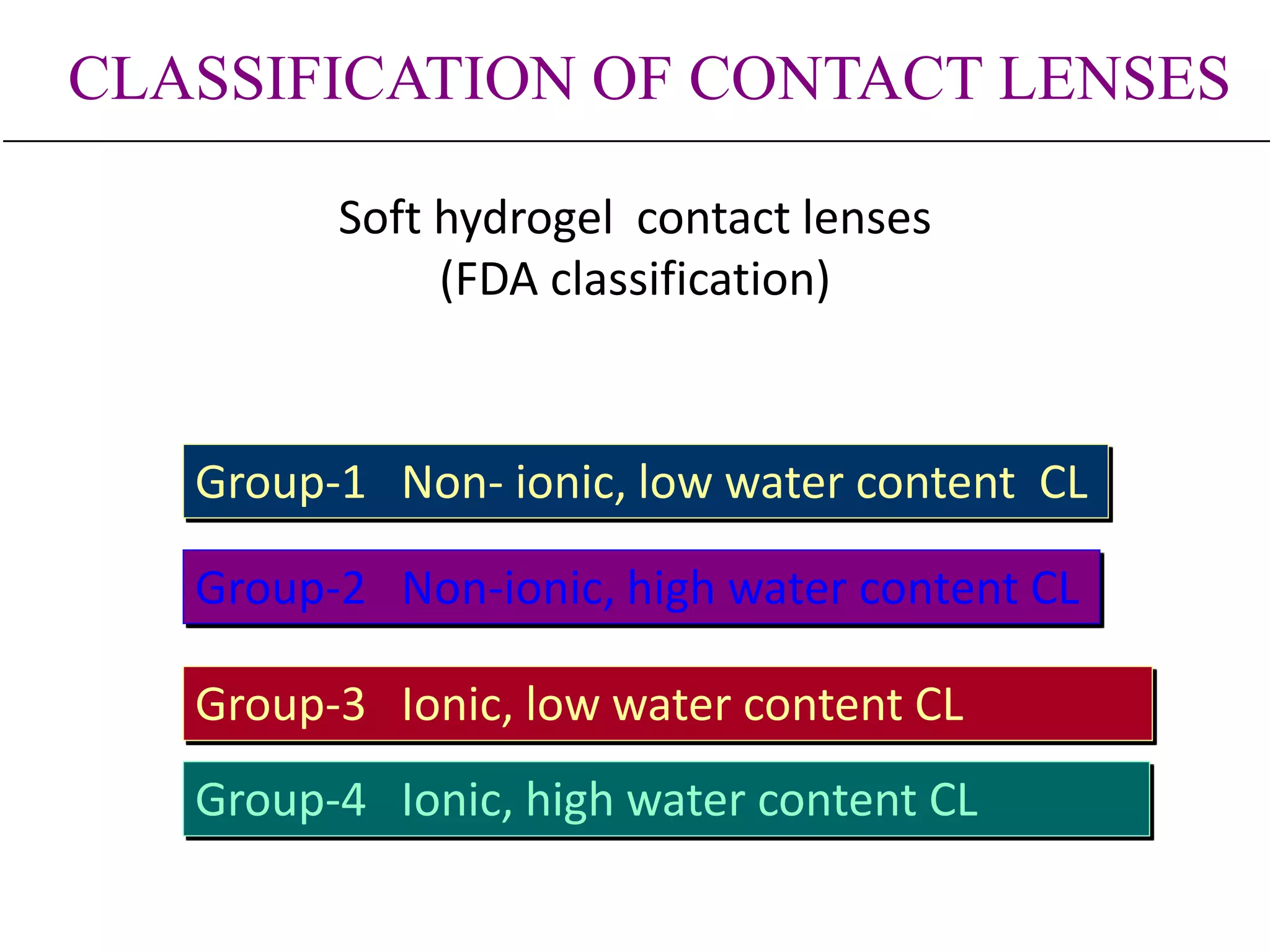

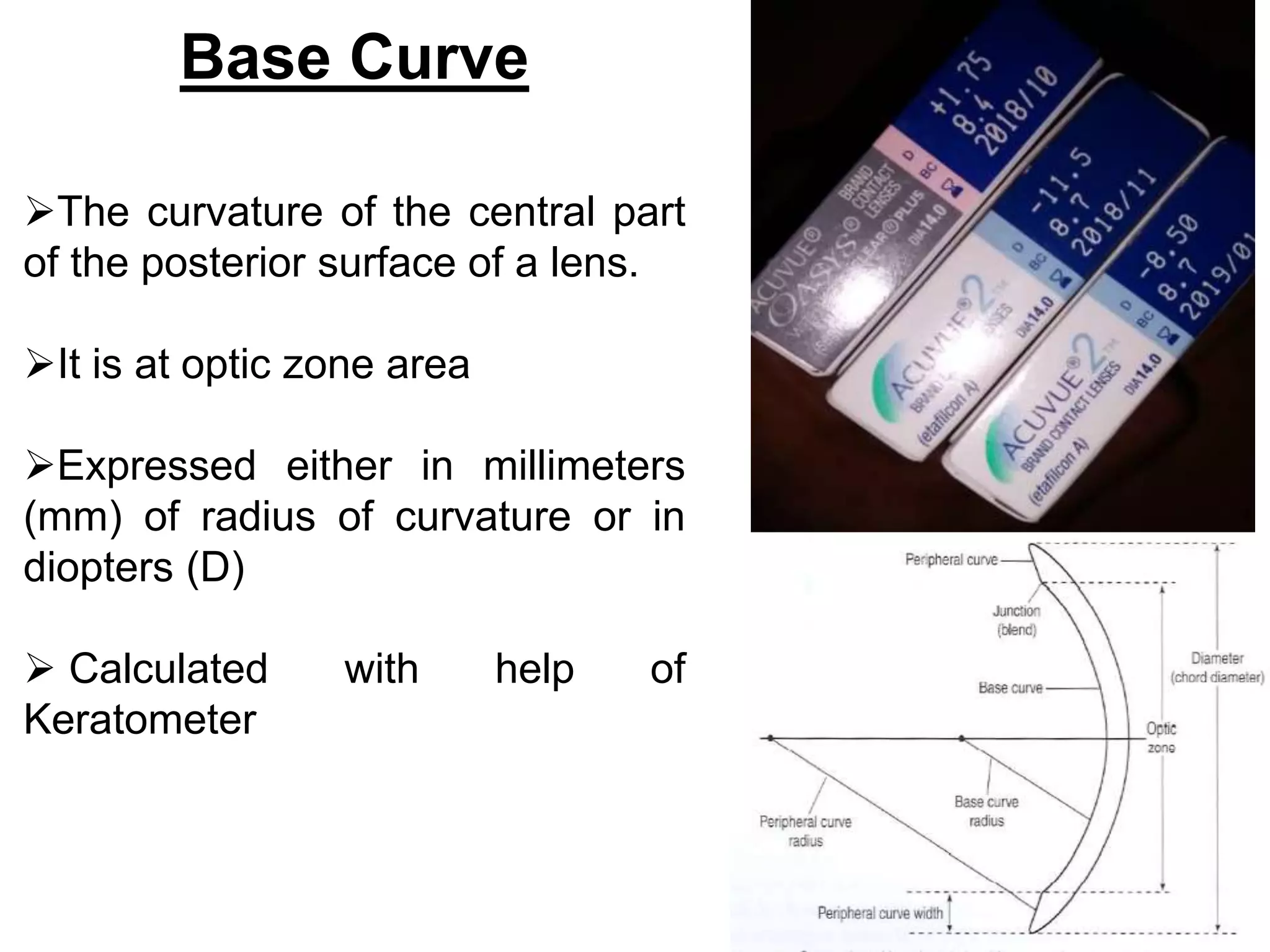

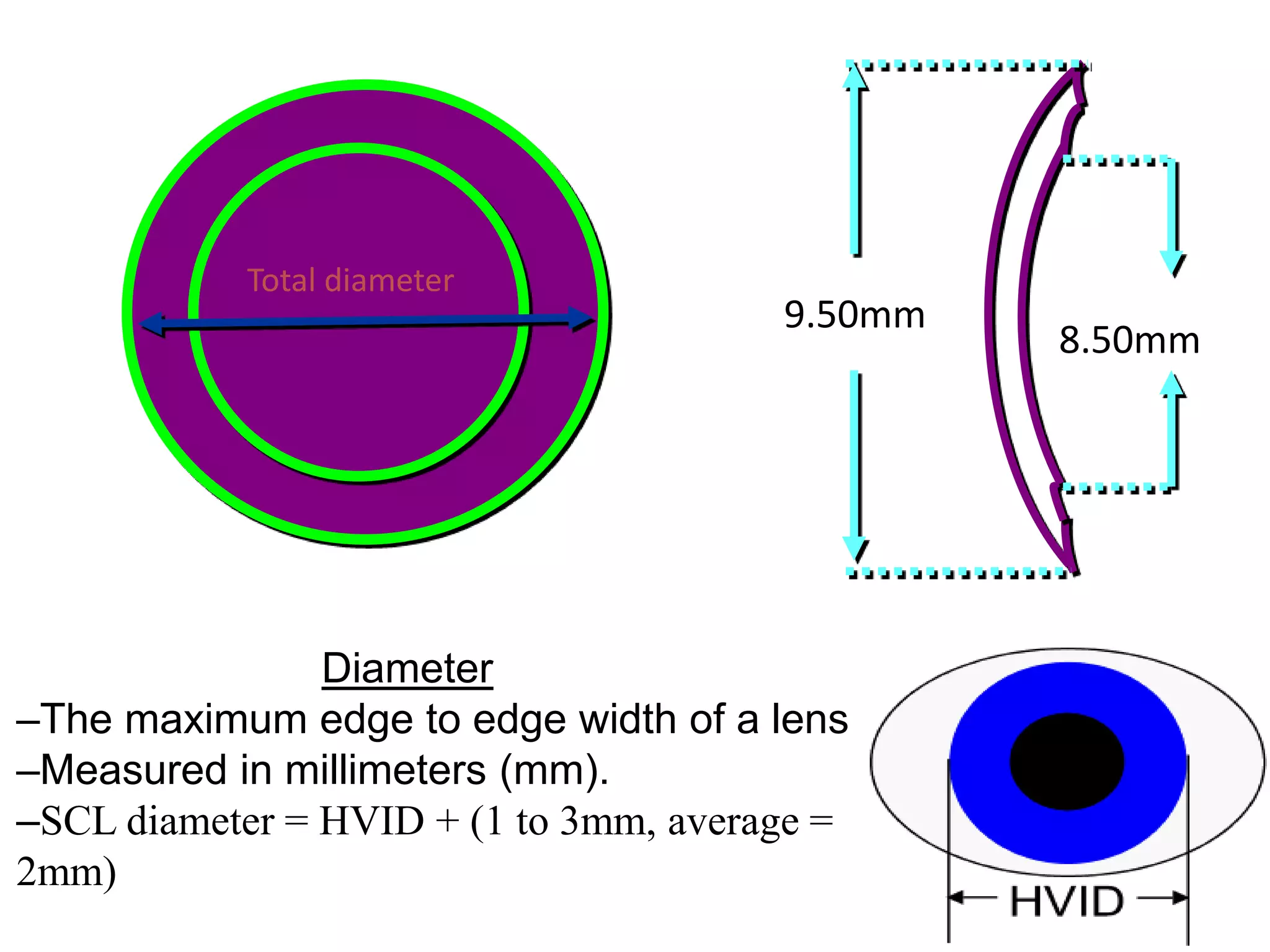

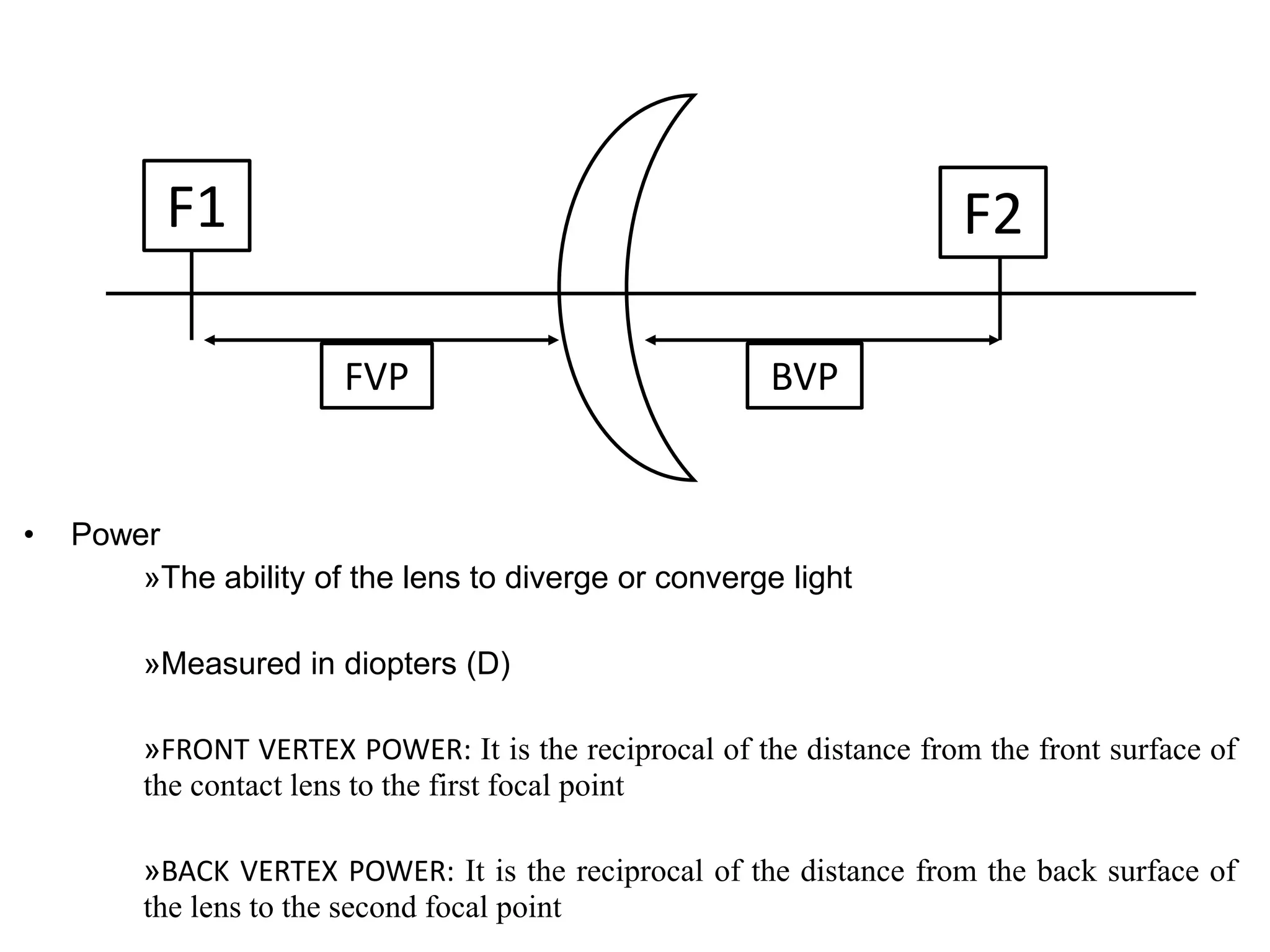

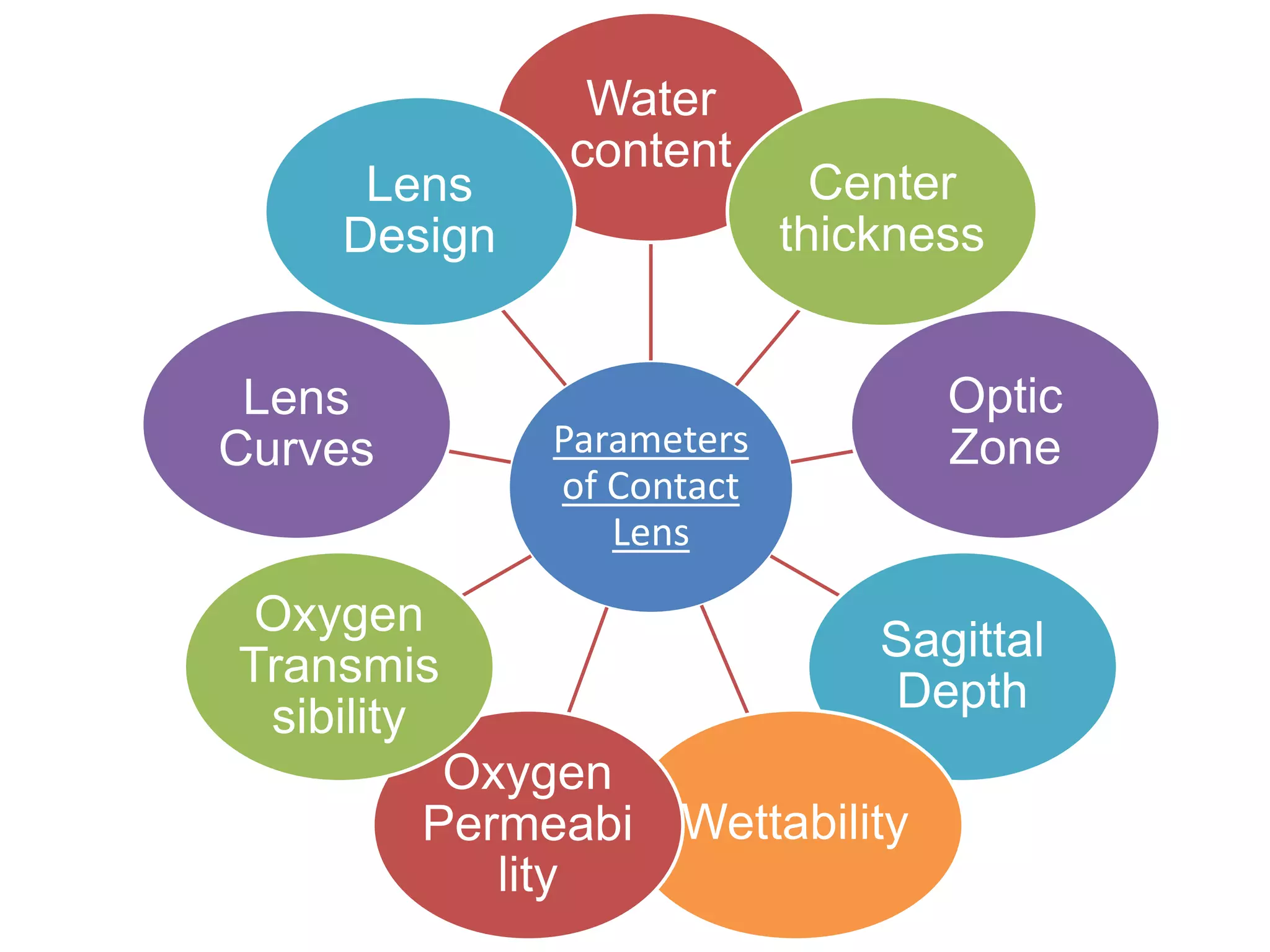

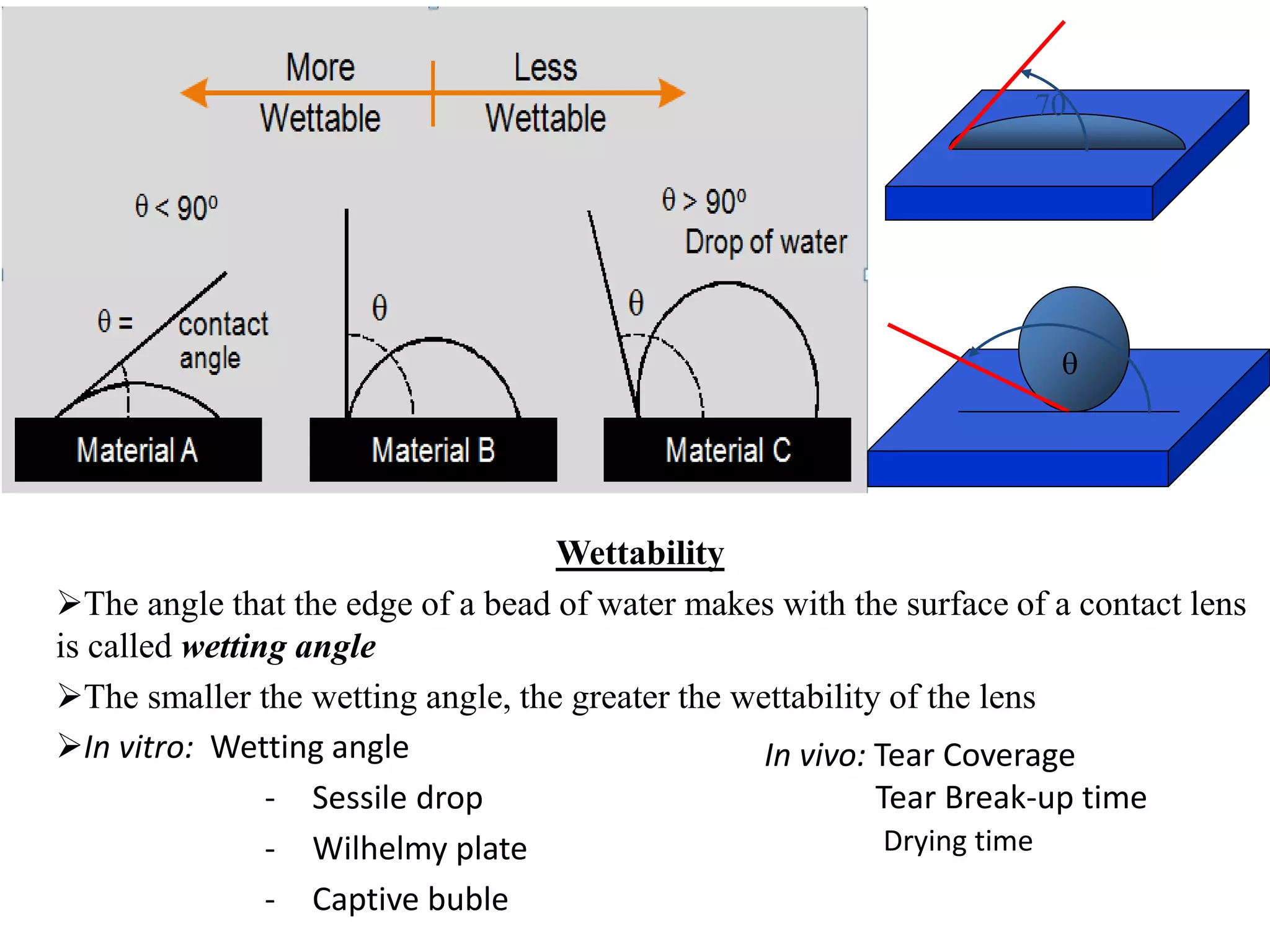

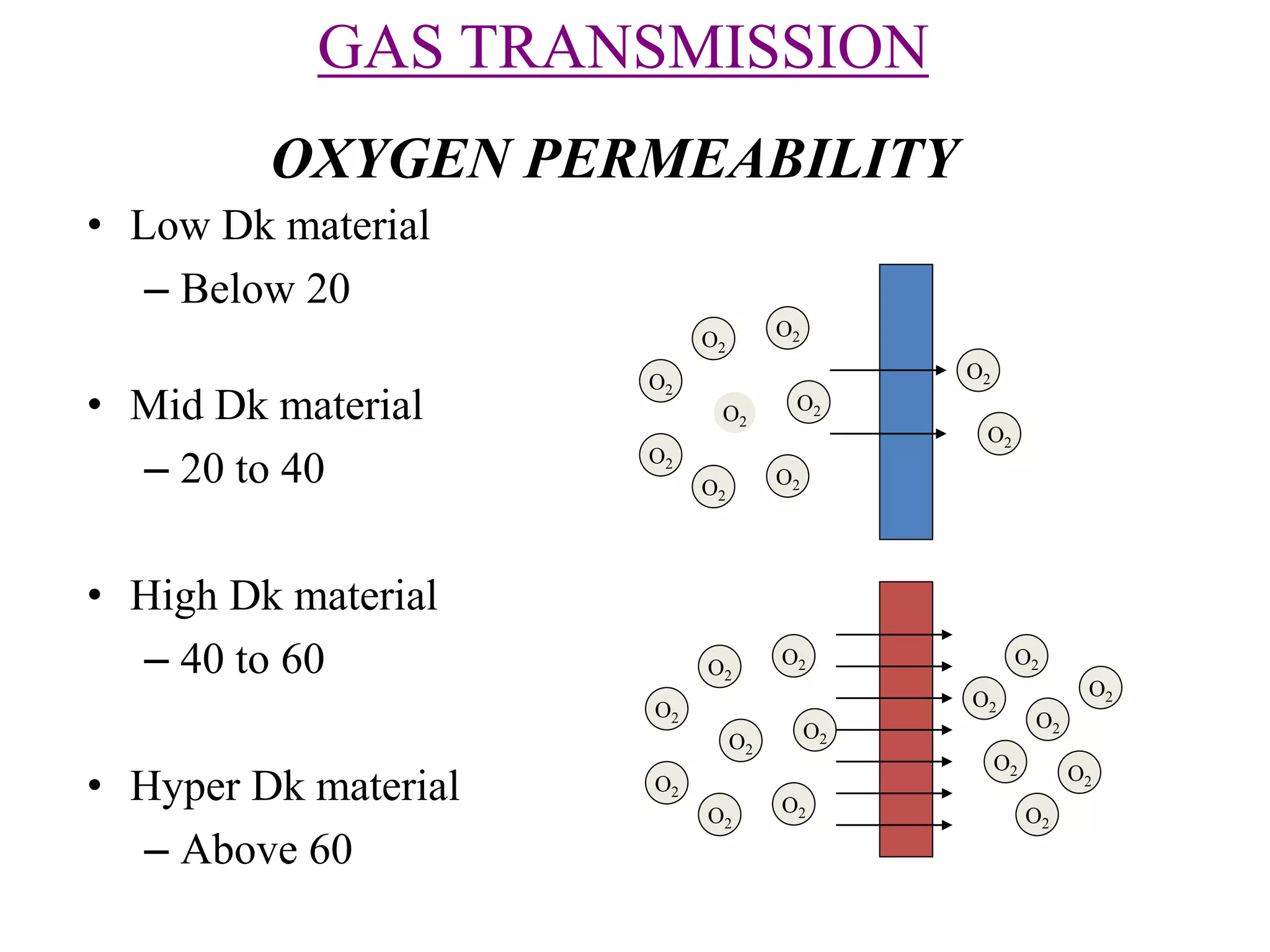

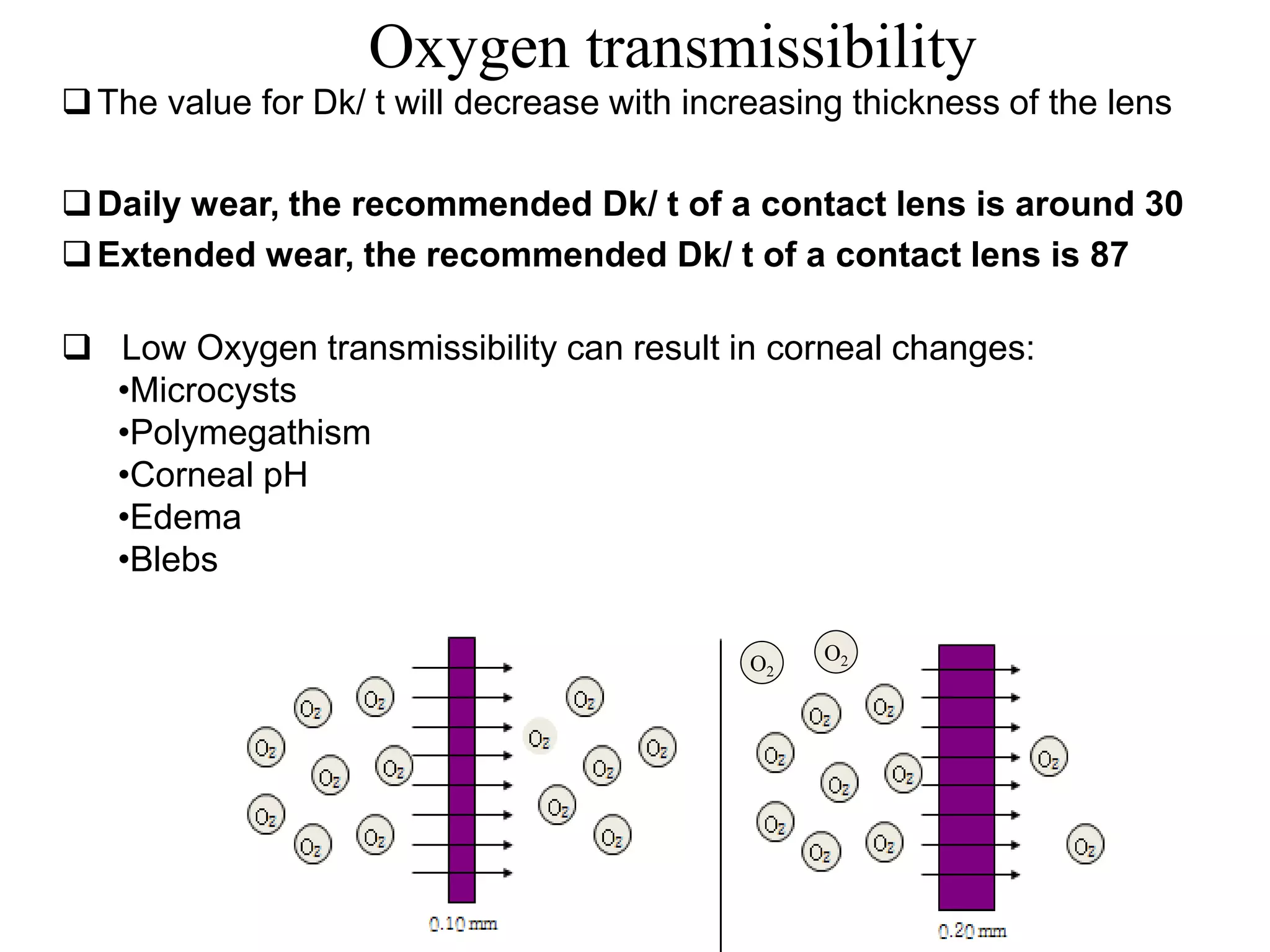

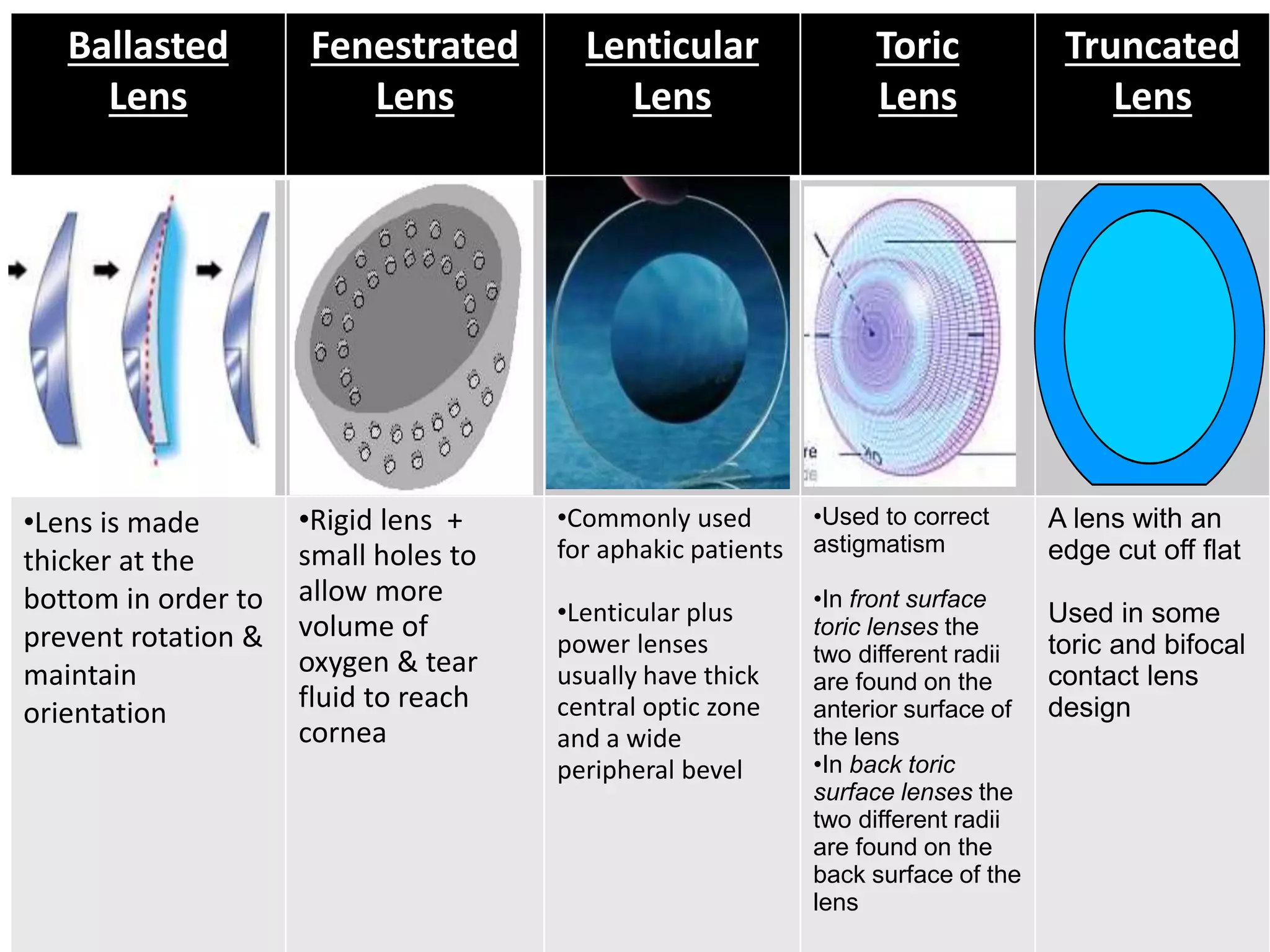

This document provides a history of contact lenses, including early sketches by Leonardo Da Vinci and Rene Descartes, and developments made by Adolf Fick, Fa Muller and Sons, and Carl Zeiss in the late 19th century. It discusses the evolution of materials from PMMA to silicone, hydrogel, and various surface treatments. Contact lenses are classified based on purpose, anatomical location, material, water content, and wearing schedule. Parameters like base curve, diameter, power, and various lens designs are also outlined.