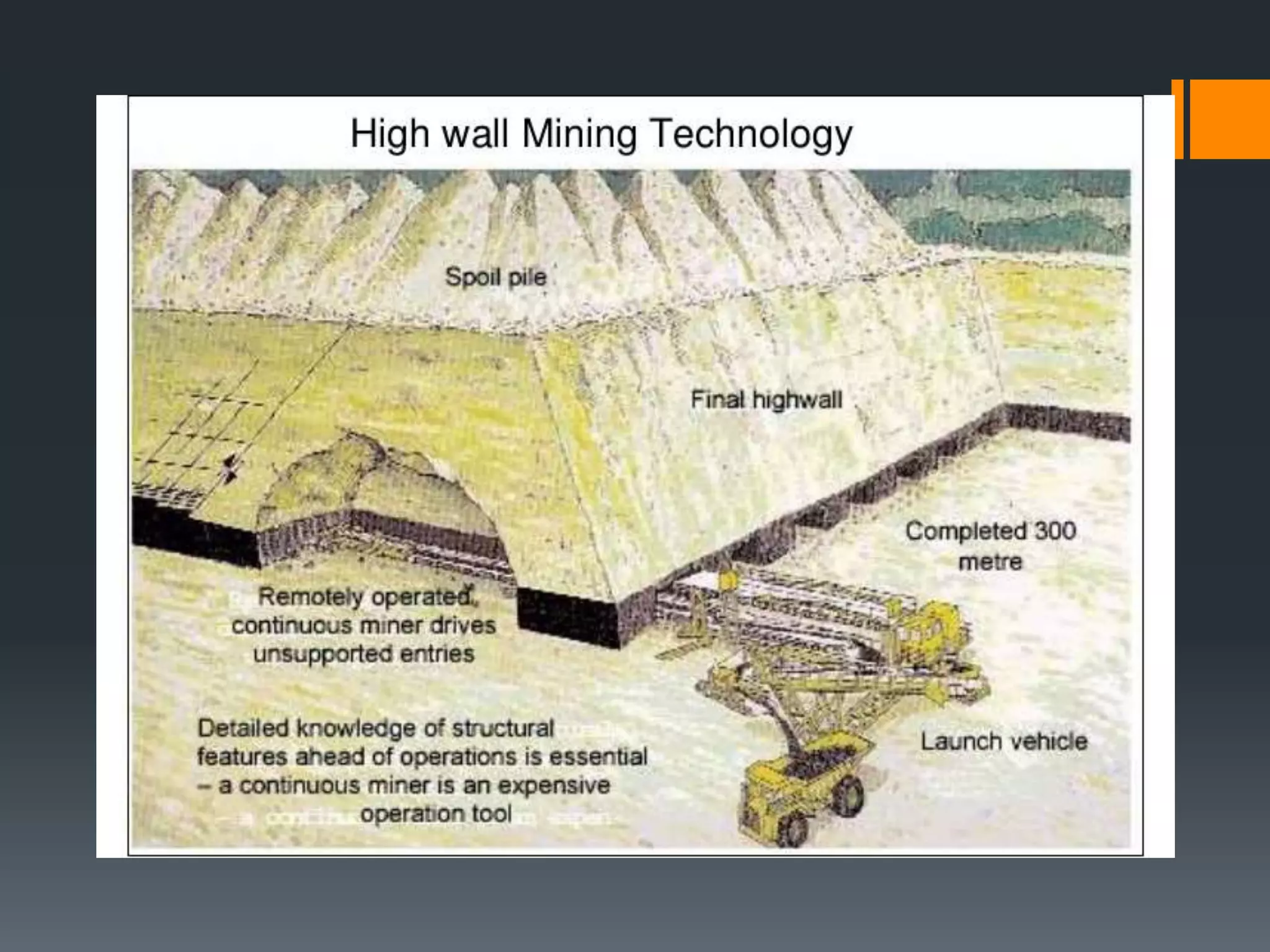

This document discusses high wall mining, which is a remotely operated mining method used to extract coal from thin seams in exposed faces of overburden and coal in surface mines. It involves driving parallel entries into the coal seam from the high wall face without roof support using a continuous miner machine equipped with a cutter head and push beams. The miner can penetrate nearly 300 meters into the coal seam. High wall mining provides an economical way to extract coal reserves locked up in the high wall and can be used when open pit mining limits have been reached or for thin seams where conventional mining is not viable. It has advantages of high coal recovery rates, safety due to lack of manned entry, and low establishment costs.