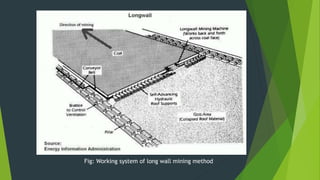

This document discusses longwall mining, a method of underground coal mining. Longwall mining involves slicing off a long wall of coal in sections that are typically 0.6-1.0 meters thick and 3-4 km long by 250-400m wide. The document outlines the equipment used in longwall mining such as powered roof supports, shearers, conveyors. It also discusses the advantages of longwall mining including high recovery rates and safety. Reasons for the slow adoption of longwall mining in India include management problems from integrating it with conventional mining and difficulties with the geological and equipment maintenance challenges. Future needs include improving spare parts management, workshops, personnel training and indigenization of equipment.