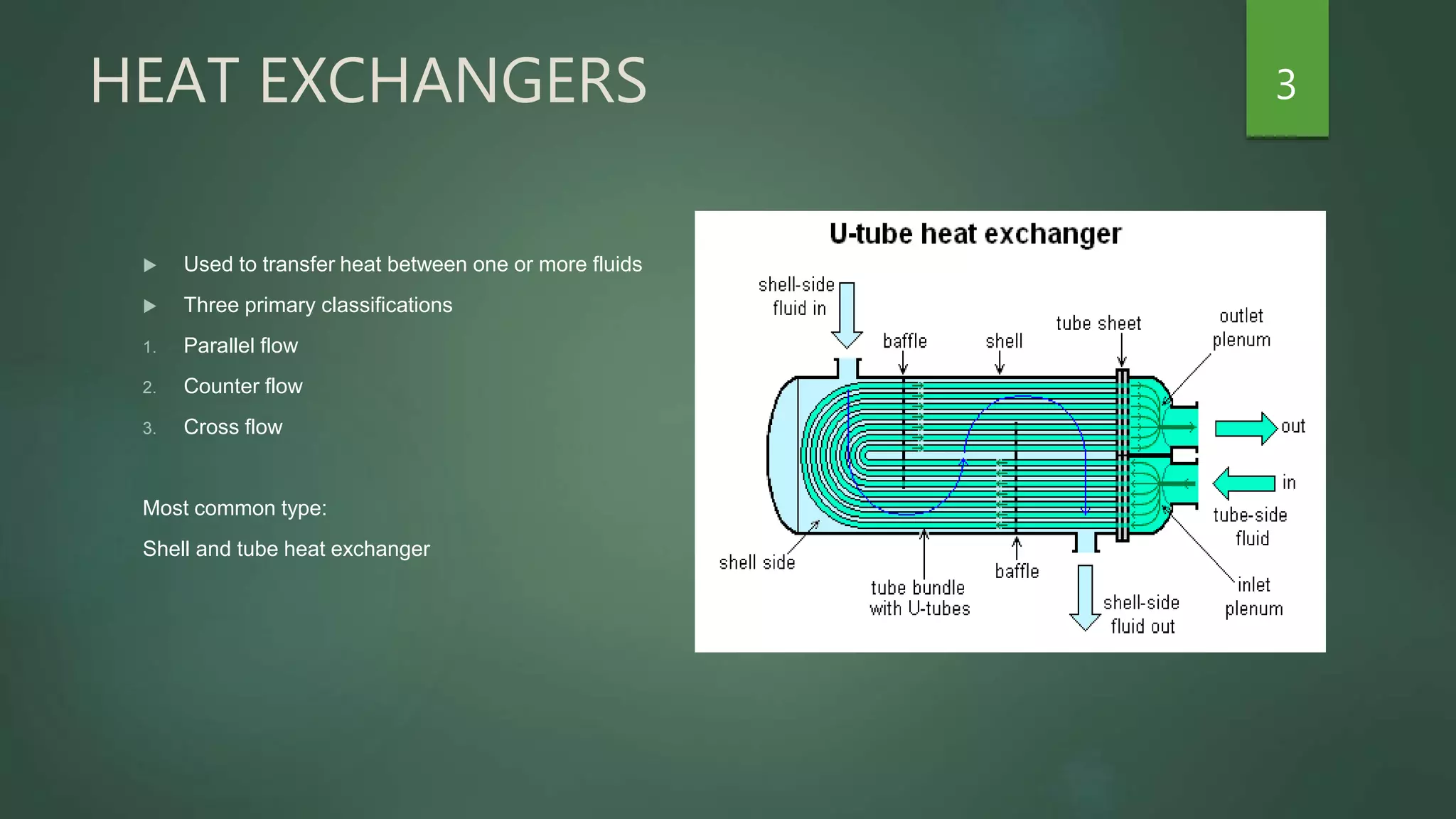

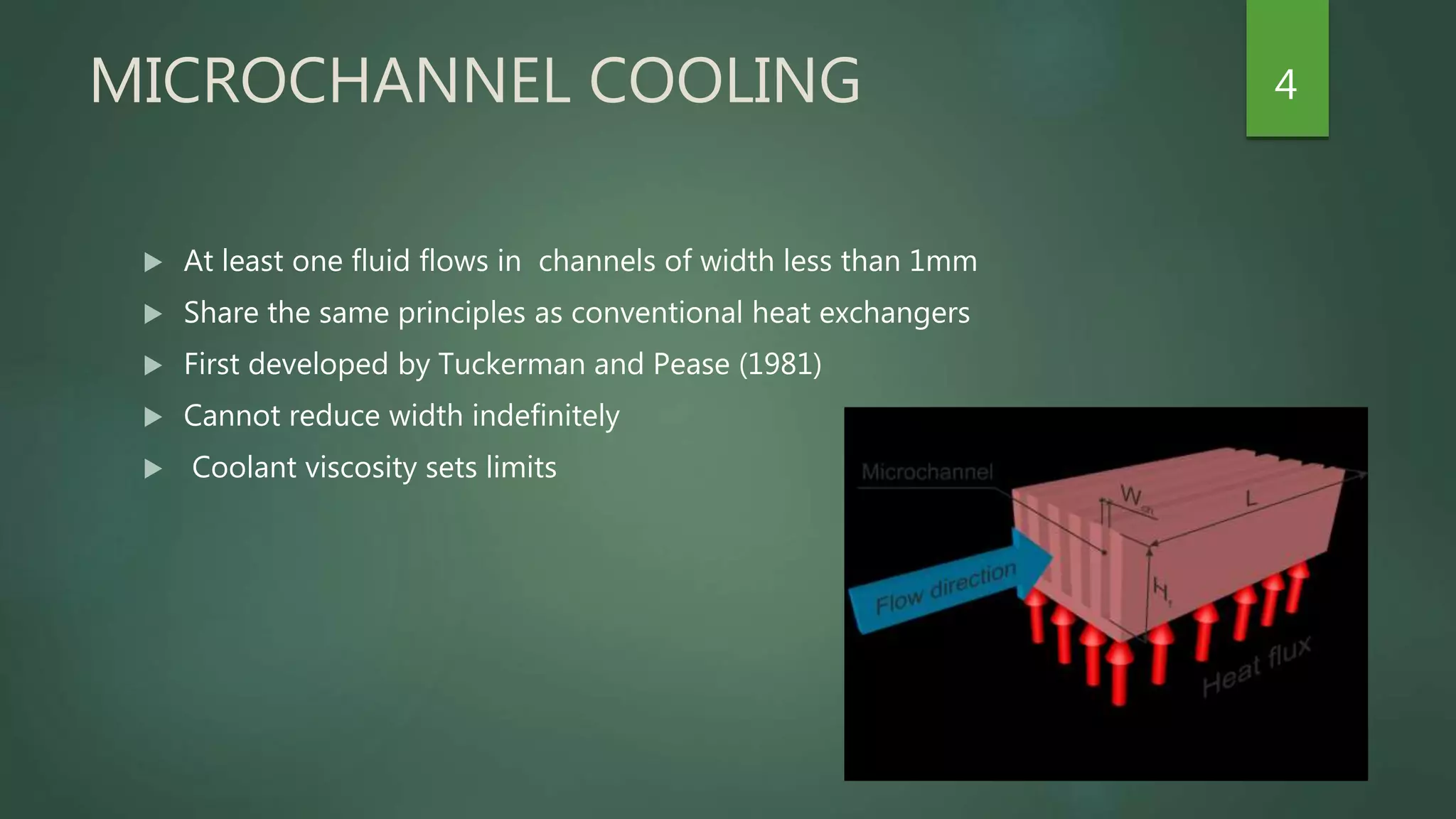

This document discusses heat transfer in microchannels. It begins by defining microchannels as channels less than 1mm wide used for heat exchange. Microchannels allow for higher heat flux transfer due to their small size. They have various applications, especially in cooling electronics. The document outlines different channel designs, manufacturing methods, coolants used like nanofluids, and limitations of microchannels. It concludes that microchannels enable high heat flux transfer and have significant potential for further development.