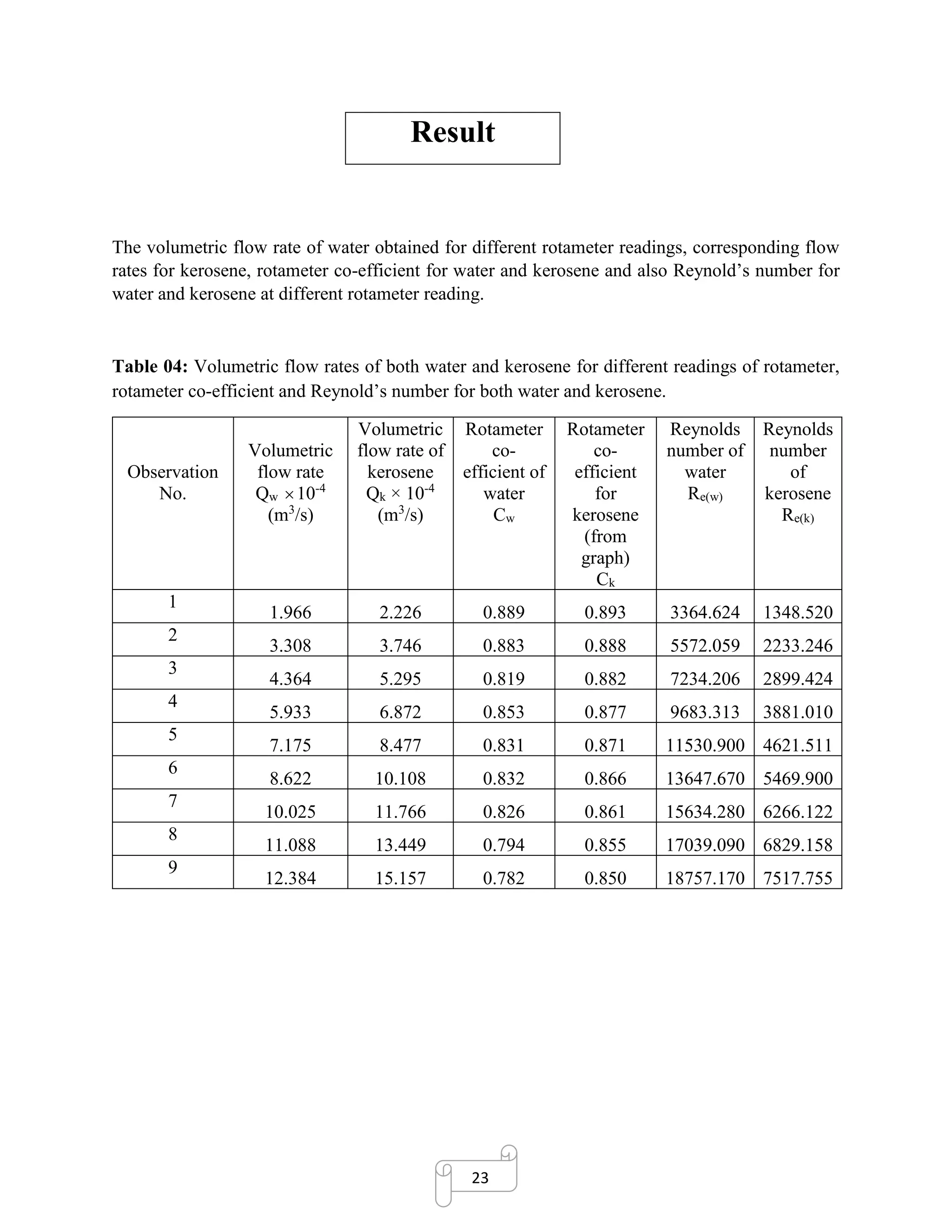

The study calibrated a rotameter for measuring the flow rates of multiple fluids. To calibrate the rotameter, the volumetric flow rate of water was measured for different rotameter readings by collecting water in a bucket over timed intervals. From the water flow rate readings, the rotameter coefficient (C) and Reynolds number (Re) were calculated and plotted against each other to obtain the calibration curve, which allows determining the flow rates of other fluids like kerosene from their properties and the rotameter reading.

![8

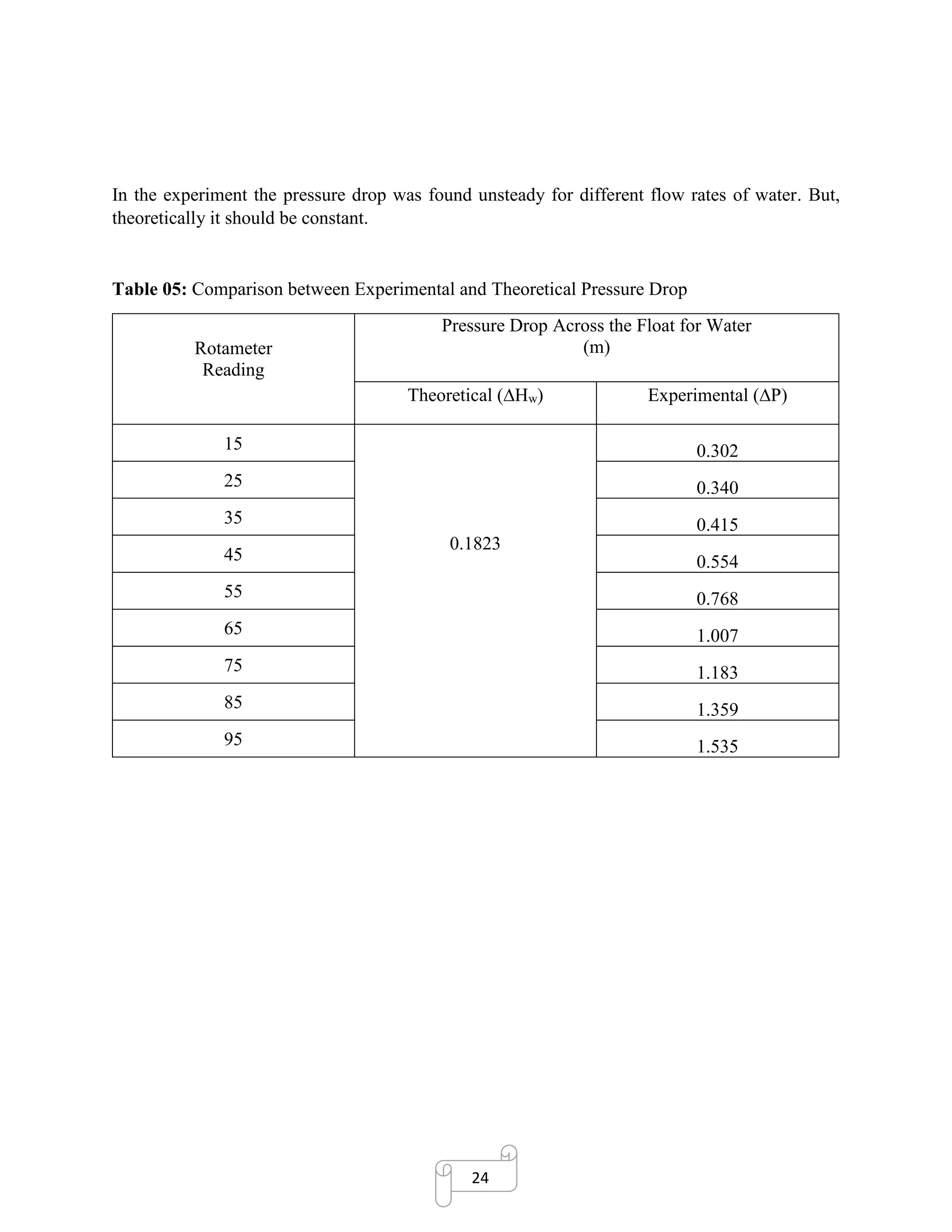

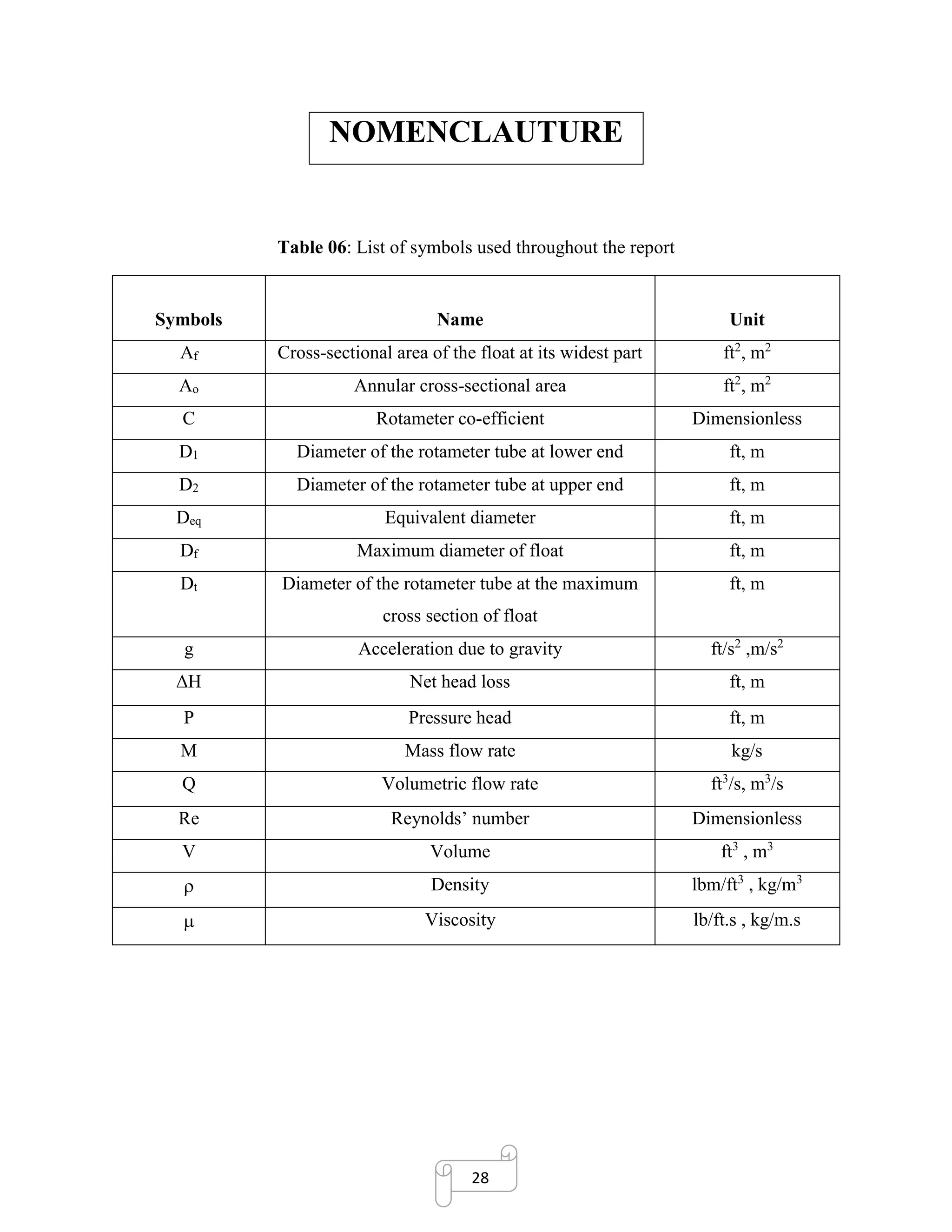

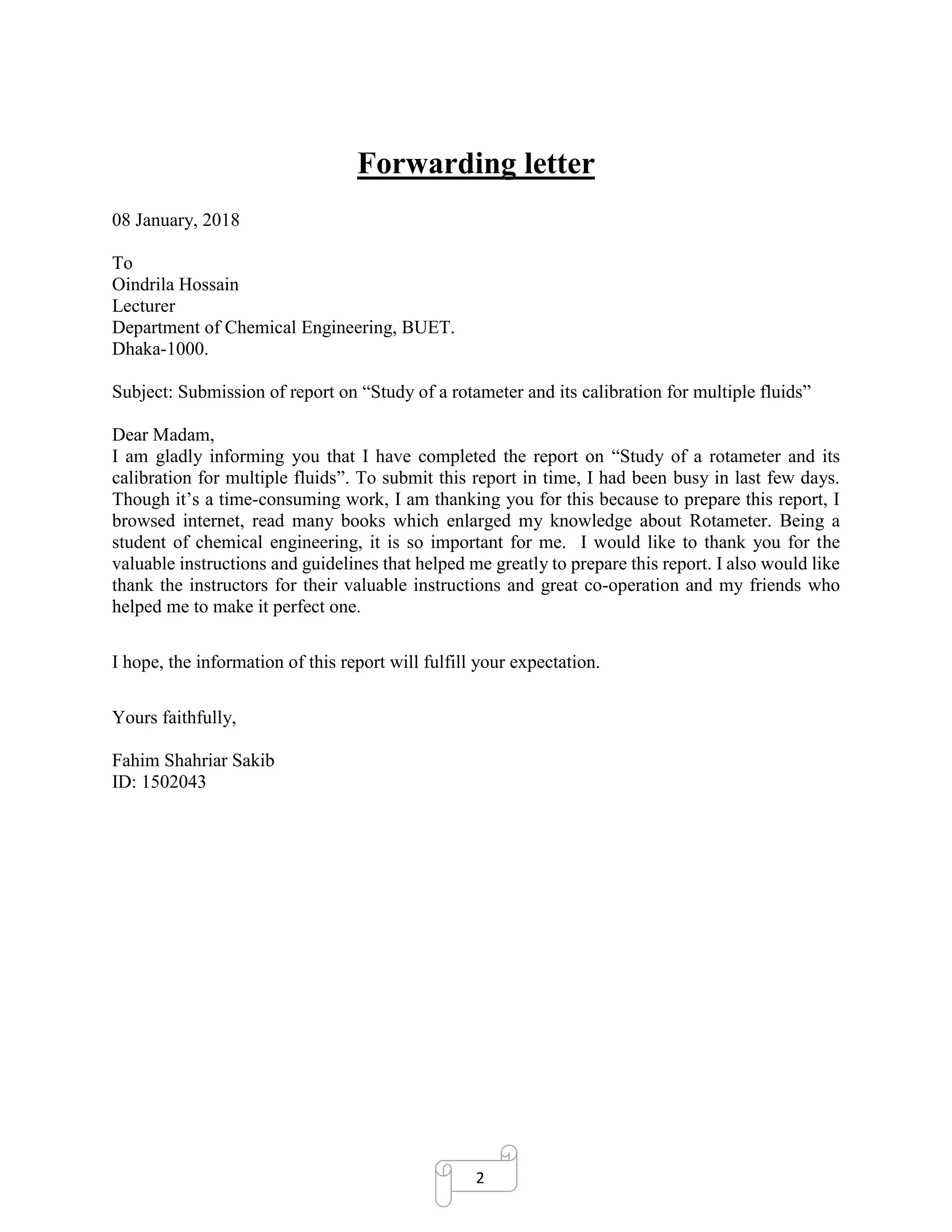

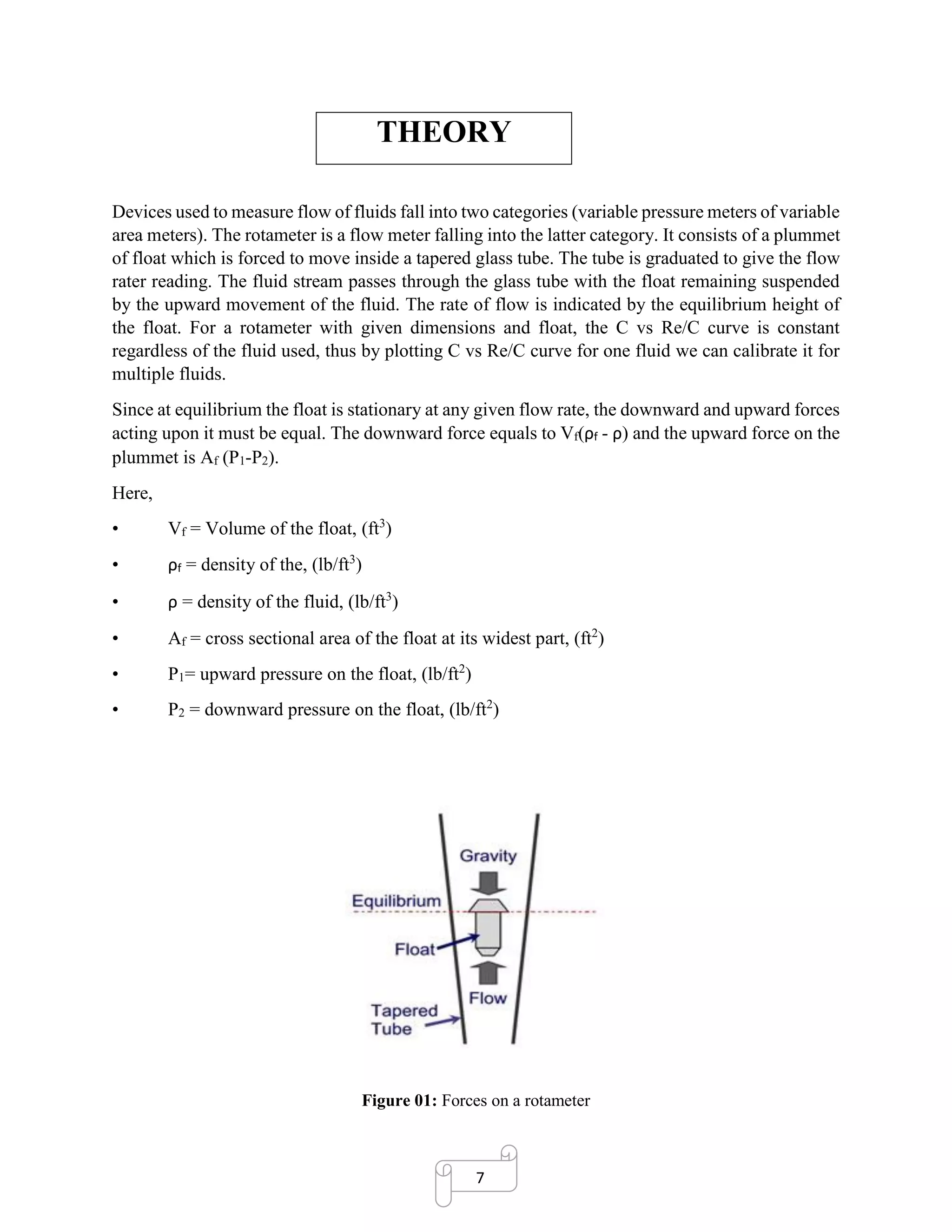

Head loss across the annulus is seen to depend on float and liquid characteristics only. Since a

rotameter can be considered an orifice meter with variable aperture. The flow equation for an

orifice is therefore applicable for a rotameter.

V = C √2𝑔 𝐻 ……………………………. (1)

Where,

V =average linear velocity of the fluid through the annulus, ft/sec

C = rotameter co-efficient, dimensionless

g = acceleration due to gravity

H = Net head loss across the annulus = Vf (

𝑓−

𝐴 𝑓

)

Now, v = Q/Ao (ft/sec).

Where Q = volumetric flow rate, (ft3

/sec.)

Ao = annulus cross sectional between float and tube, ft2

V = Q/Ao = C √2𝑔 𝐻 = C√2𝑔Vf(

𝑓−

𝐴 𝑓

)

Solving for C, we have

C =

𝑄

𝐴 𝑜√[

2𝑔𝑉 𝑓( 𝑓−)

𝐴 𝑓

]

=

𝑄

𝐴 𝑜√(2𝑔 𝐻)

……………………. (2)

With known Q for water (Qw), known ΔHw and known Ao, for a corresponding rotameter reading,

we can thus find C using (2).

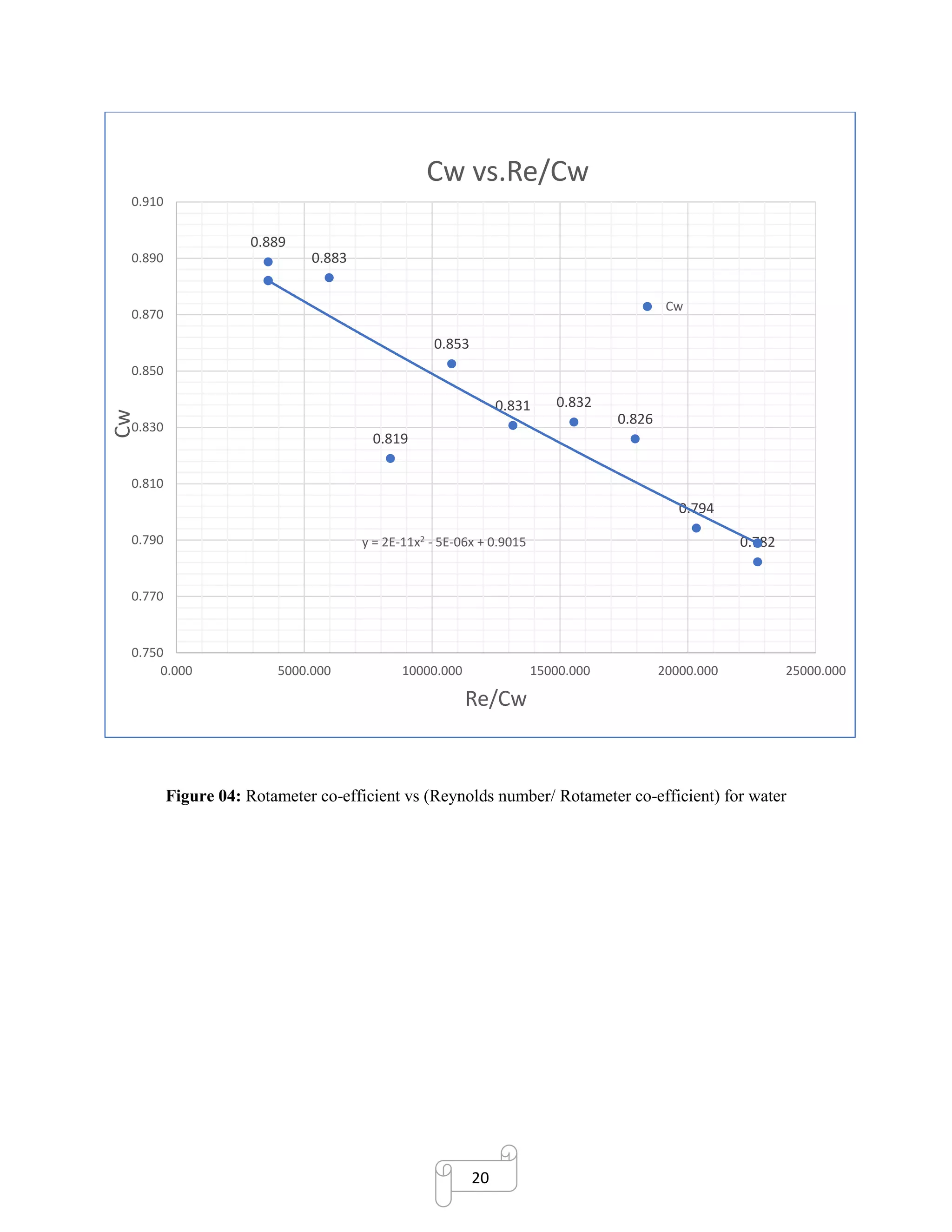

Thus, we can find a series of C values for various rotameter readings. Also, we can find Re

(Reynolds’ number) at these rotameter readings. This helps us to plot C vs Re/C curve

(Calibration curve).](https://image.slidesharecdn.com/rotametercalibrationreportformultiplefluids-180107123335/75/Rotameter-calibration-report-for-multiple-fluids-9-2048.jpg)

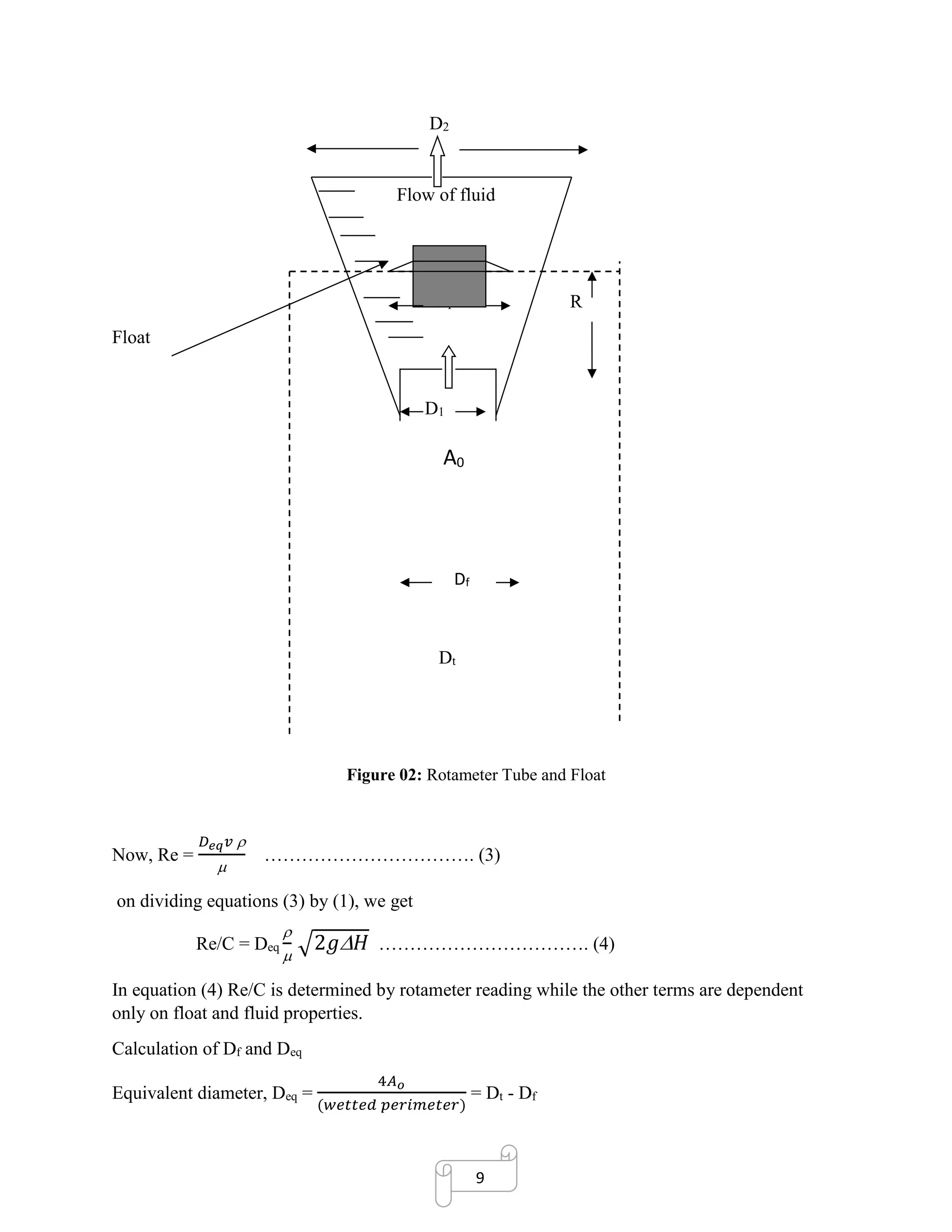

![11

APPARATUS

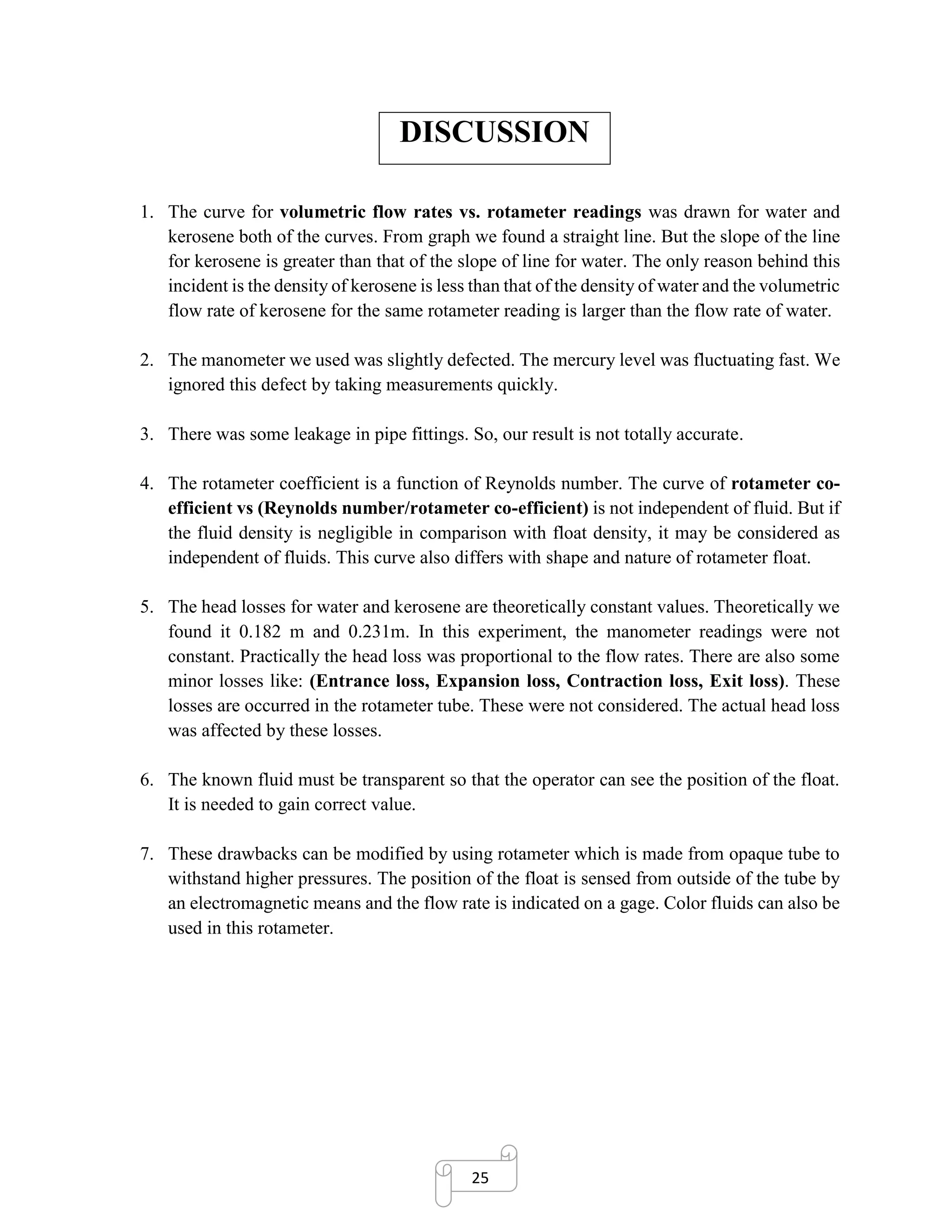

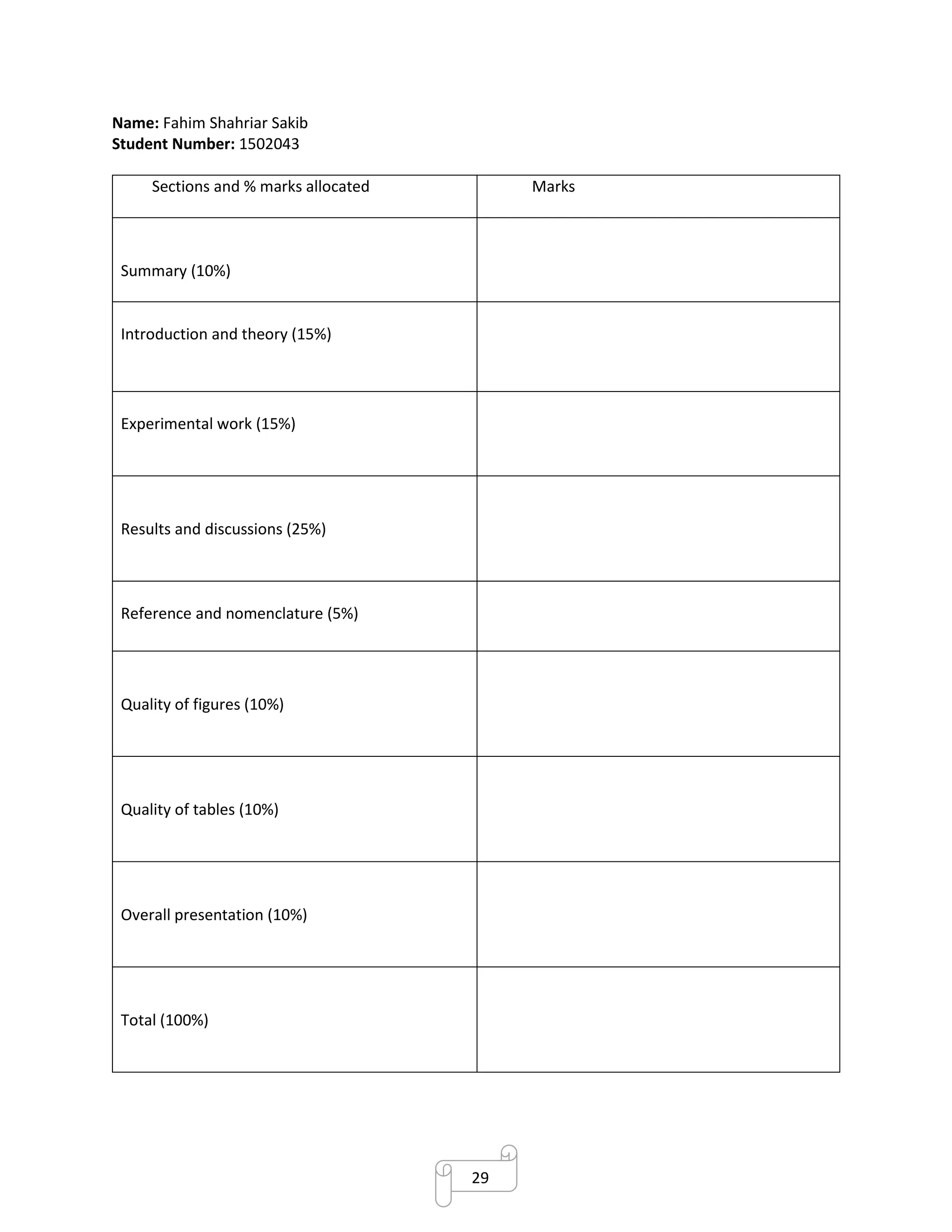

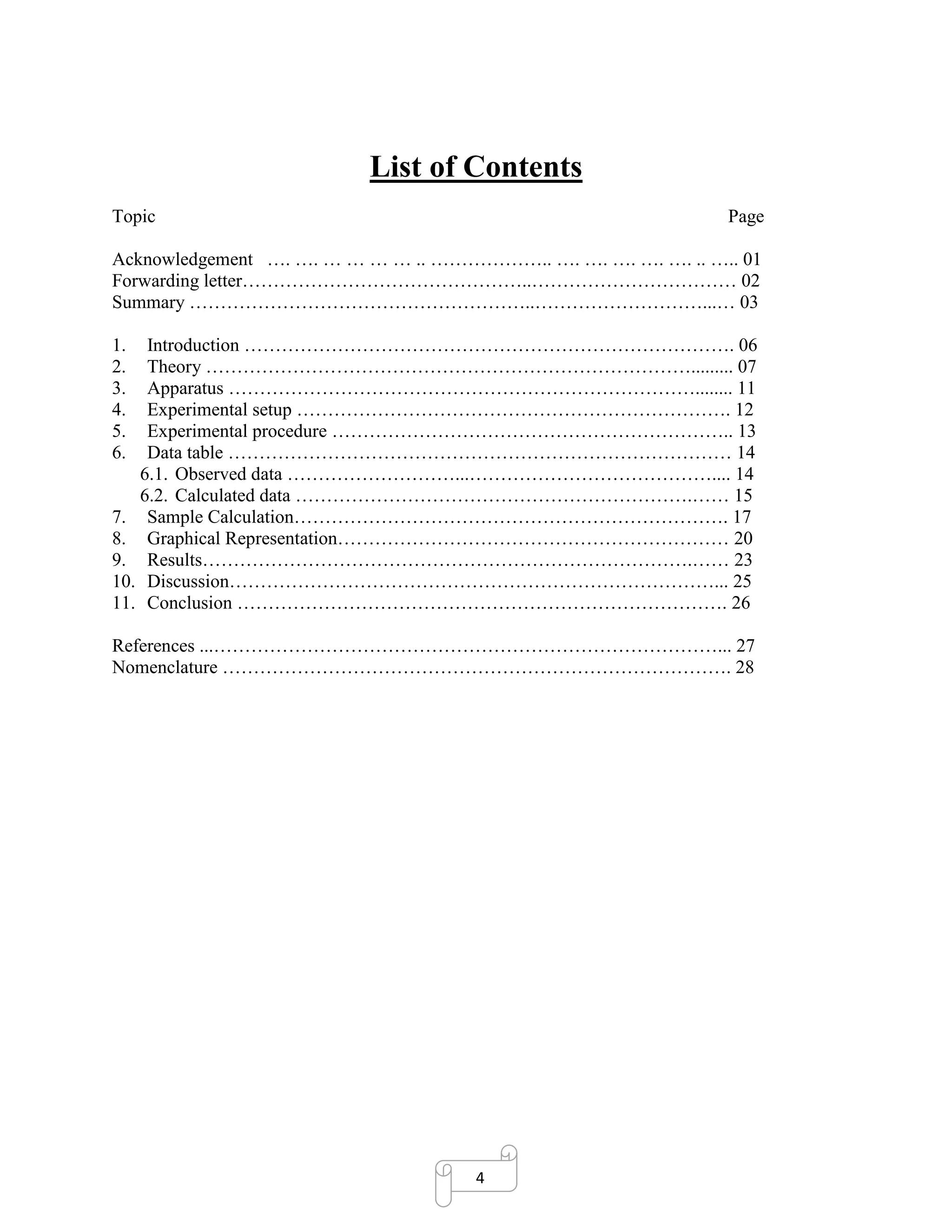

1. Rotameter – [Rotameter is a typical variable area meter consists of gradually tapered glass

mounted vertically in a frame with the large end up. Fluid flows upward through the

tapered tube and suspends freely a float (which is submerged in the fluid) Float is the

indicating element, and the greater the flow rate, the higher the float rides in the tube. The

float is shaped so that it rotates axially as the fluid passes. Floats are made in many different

shapes, with spheres and spherical ellipses being the most common. The tube is marked in

divisions, and the reading of the meter is obtained from the scale reading at the reading

edge of the float, which is taken at the largest cross section of the float.]

2. Manometer – [A meter which is used for measuring the pressure drop between two points.

It is normally ‘U’ shaped. There is a manometric fluid from which we can measure the

pressure difference. There are different types of manometer. But here, we used ‘U’ shaped

and two ways open manometer.]

3. Bucket – [A little reservoir which is used for measuring mass flow rate of a fluid. In a

period of time, we filled water in bucket and measured the mass flow rate.]

4. Stopwatch – [It is used for measuring mass flow rate. It is used for limiting the time

interval.]

5. Weighing machine – [we used it for measuring the mass of water which is taken in a time

period.]

6. Tank – [The water is reserved in tank.]

7. Pump – [It is used for flowing the water through the rotameter for proceeding the

experiment]](https://image.slidesharecdn.com/rotametercalibrationreportformultiplefluids-180107123335/75/Rotameter-calibration-report-for-multiple-fluids-12-2048.jpg)

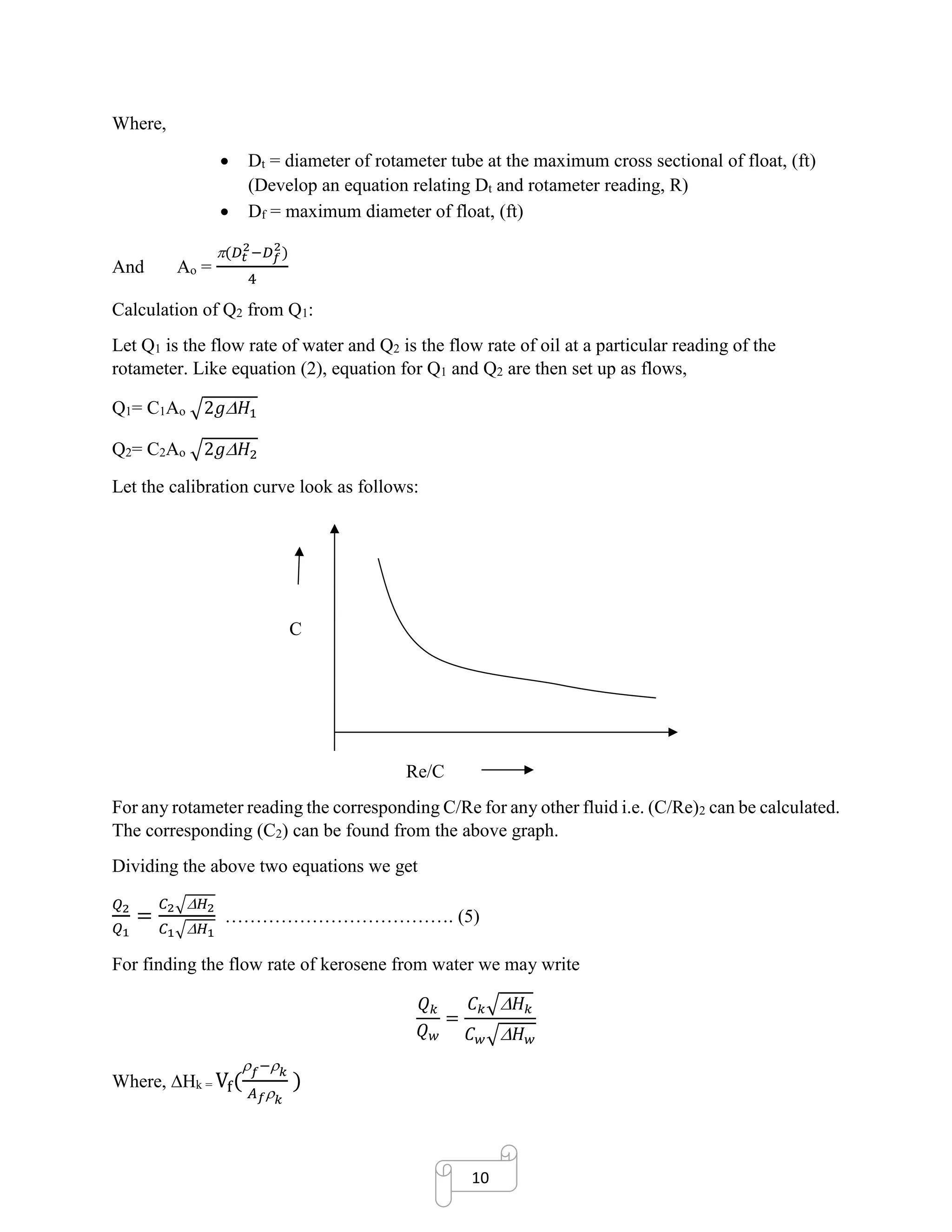

![15

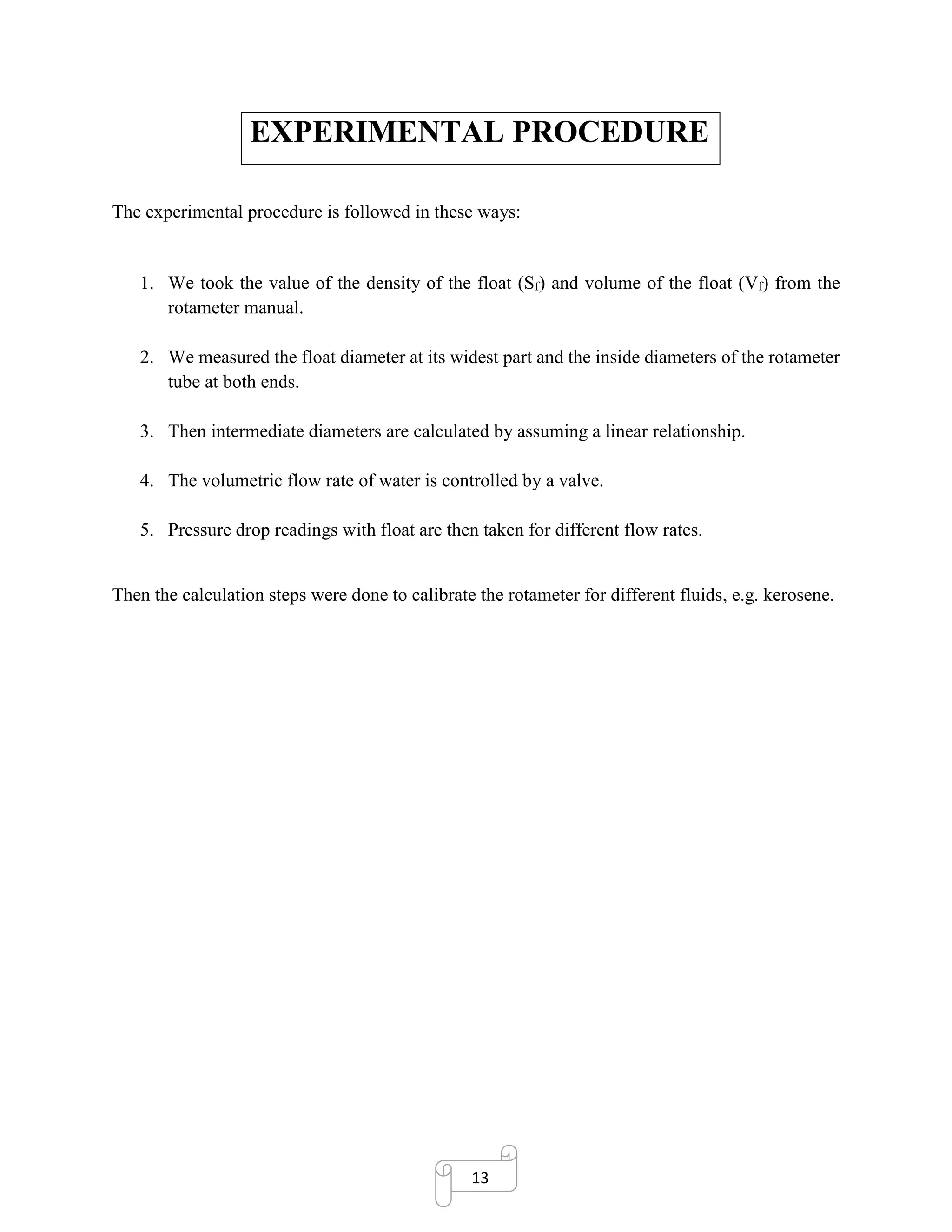

Calculated Data:

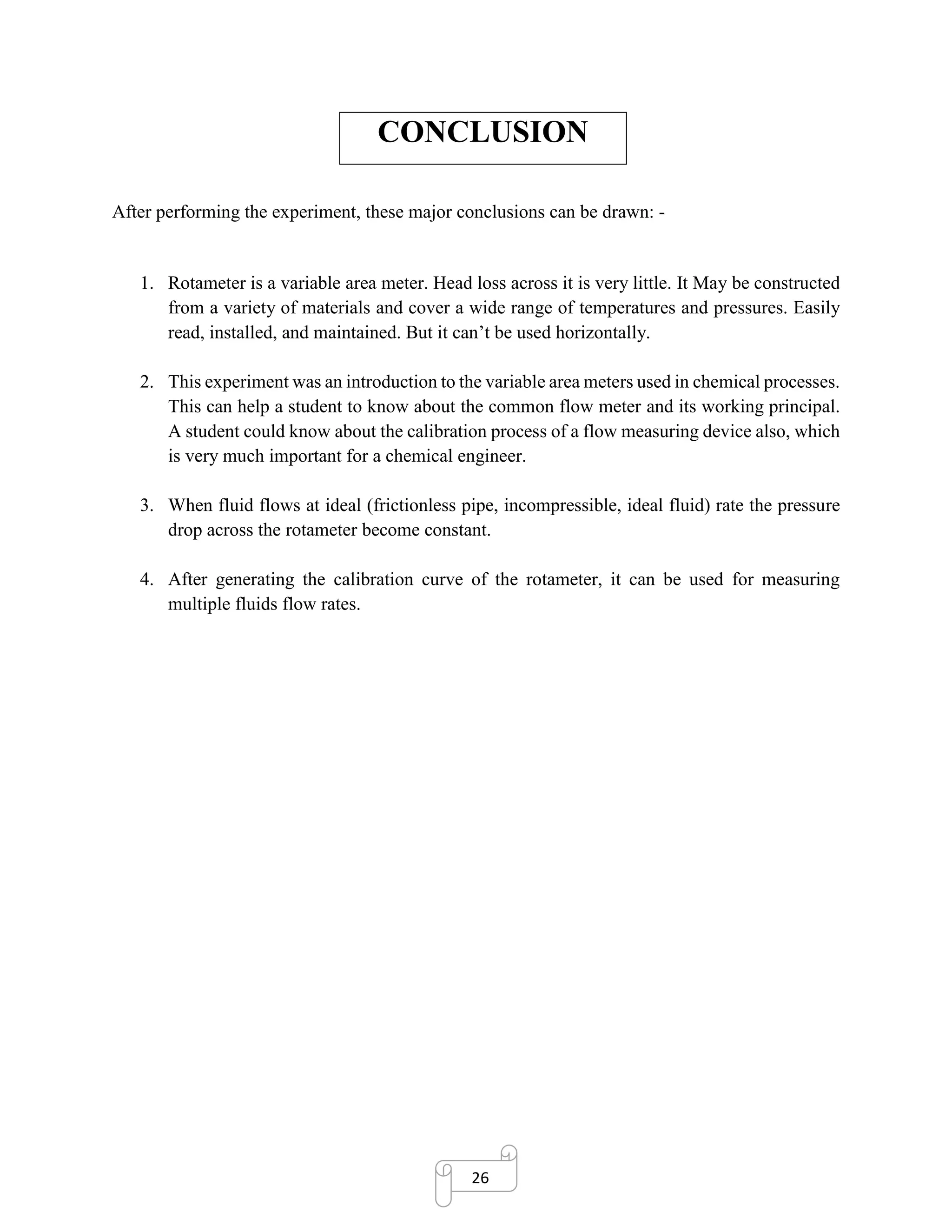

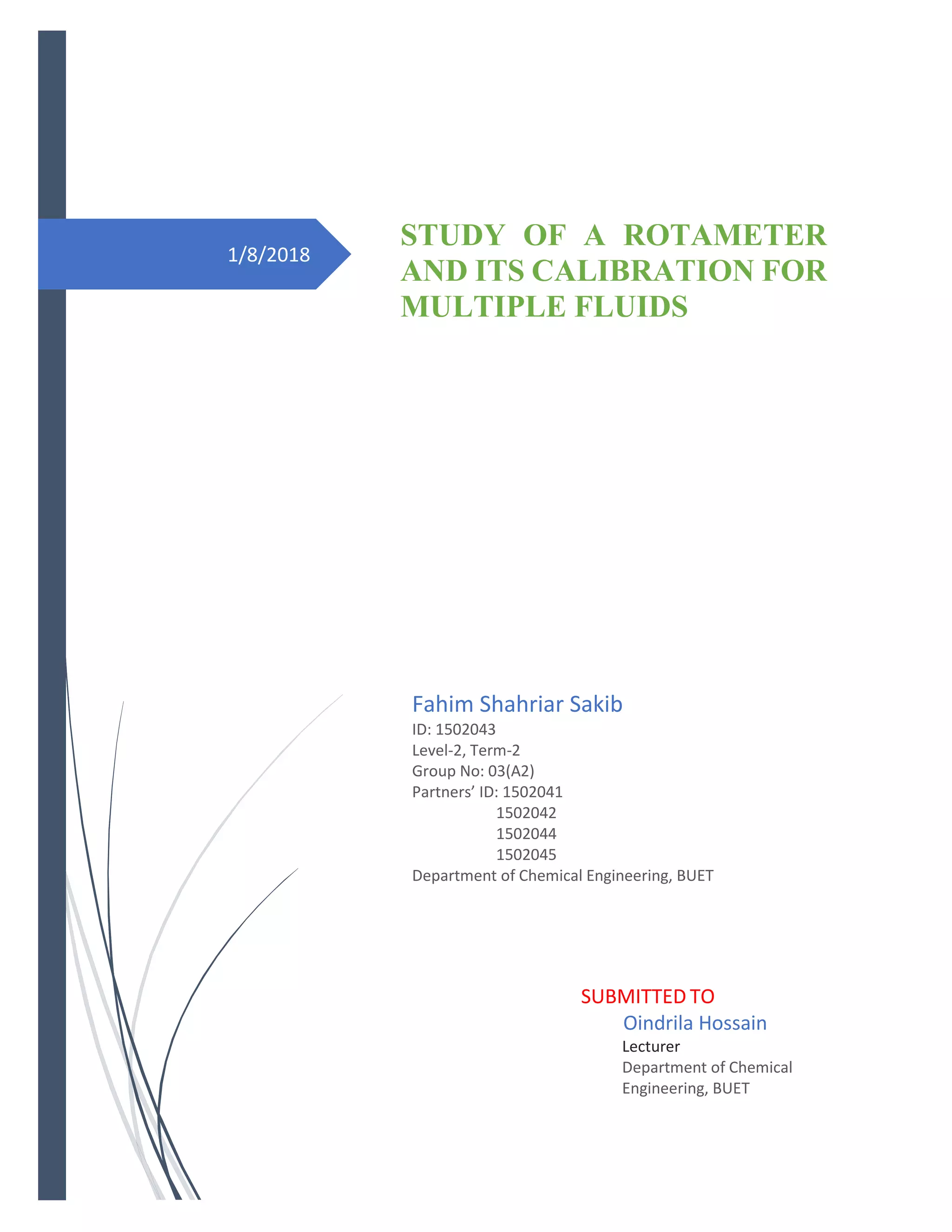

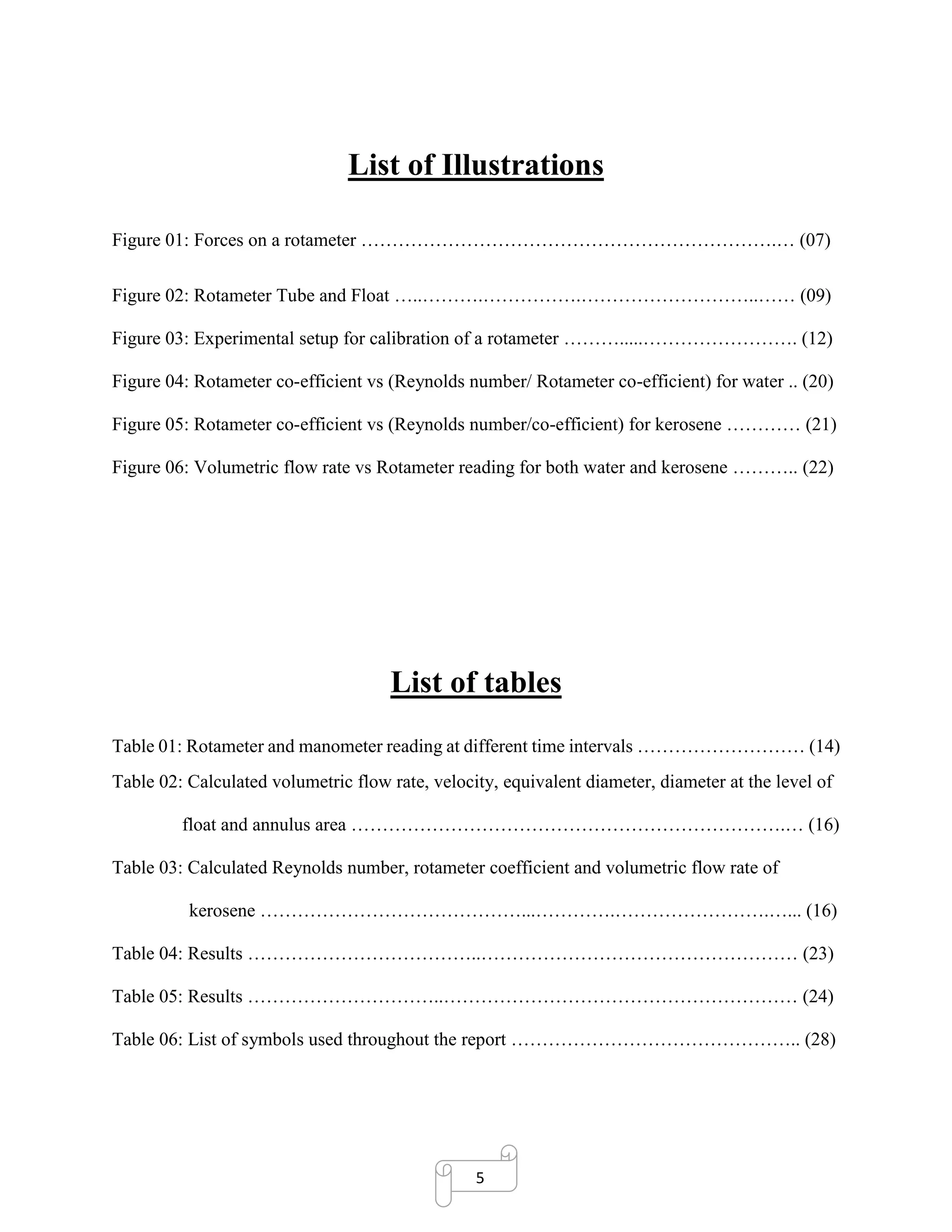

Equipment data

Diameter of rotameter tube at lower end, D1= 1.5 inch = 3.81×10-2

m

Diameter of rotameter tube at upper end, D2= 2.0 inch = 5.08×10-2

m

Total length of rotameter tube, L=100 divisions

Maximum float diameter, Df= 1.5 inch= 3.81×10-2

m

Volume of the float, Vf= 1.077×10-3

ft3

= 3.05×10-5

m3

Density of the float, ρf = 486.93 lbm/ft3

=7804.64 kg/m3

Collected data

At 22.5o

C

Density of water, ρw = 997.6 Kg/m3

Viscosity of water, µw = 8.96×10-4

Ns/m-2

[By interpolation (Ref: Daugherty, Franzini

& Finnemore, Fluid Mechanics with

Engineering Application, SI metric edition,

Page-591)]

At 200

C

Density of kerosene ρk= 808 kg/m3

Viscosity of kerosene µk = 1.92×10-3

Ns/m2

Specific weight of kerosene γk=810 kN/m3

[Ref: Daugherty, Franzini & Finnemore,

Fluid Mechanics with Engineering

Application, SI metric edition, Page-573]](https://image.slidesharecdn.com/rotametercalibrationreportformultiplefluids-180107123335/75/Rotameter-calibration-report-for-multiple-fluids-16-2048.jpg)

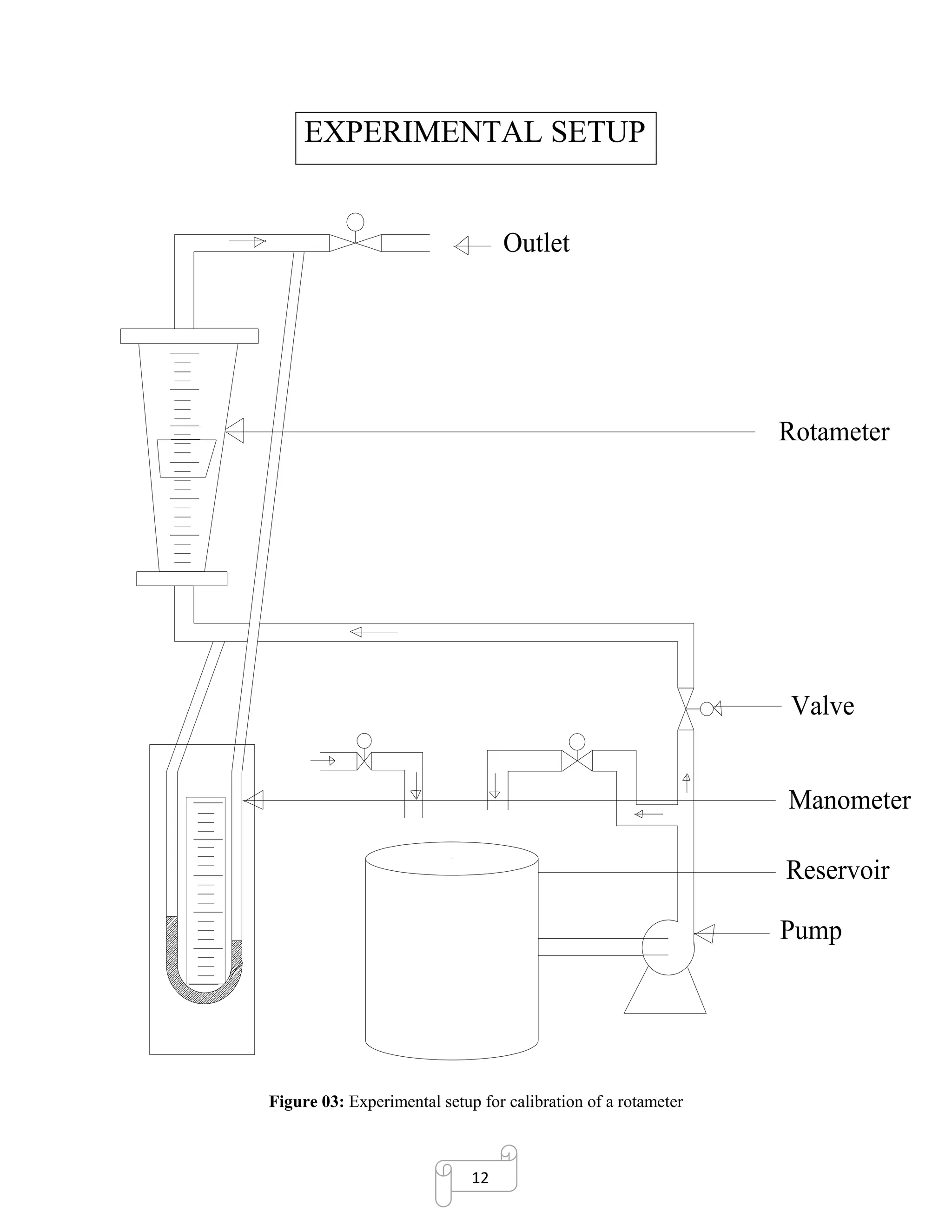

![17

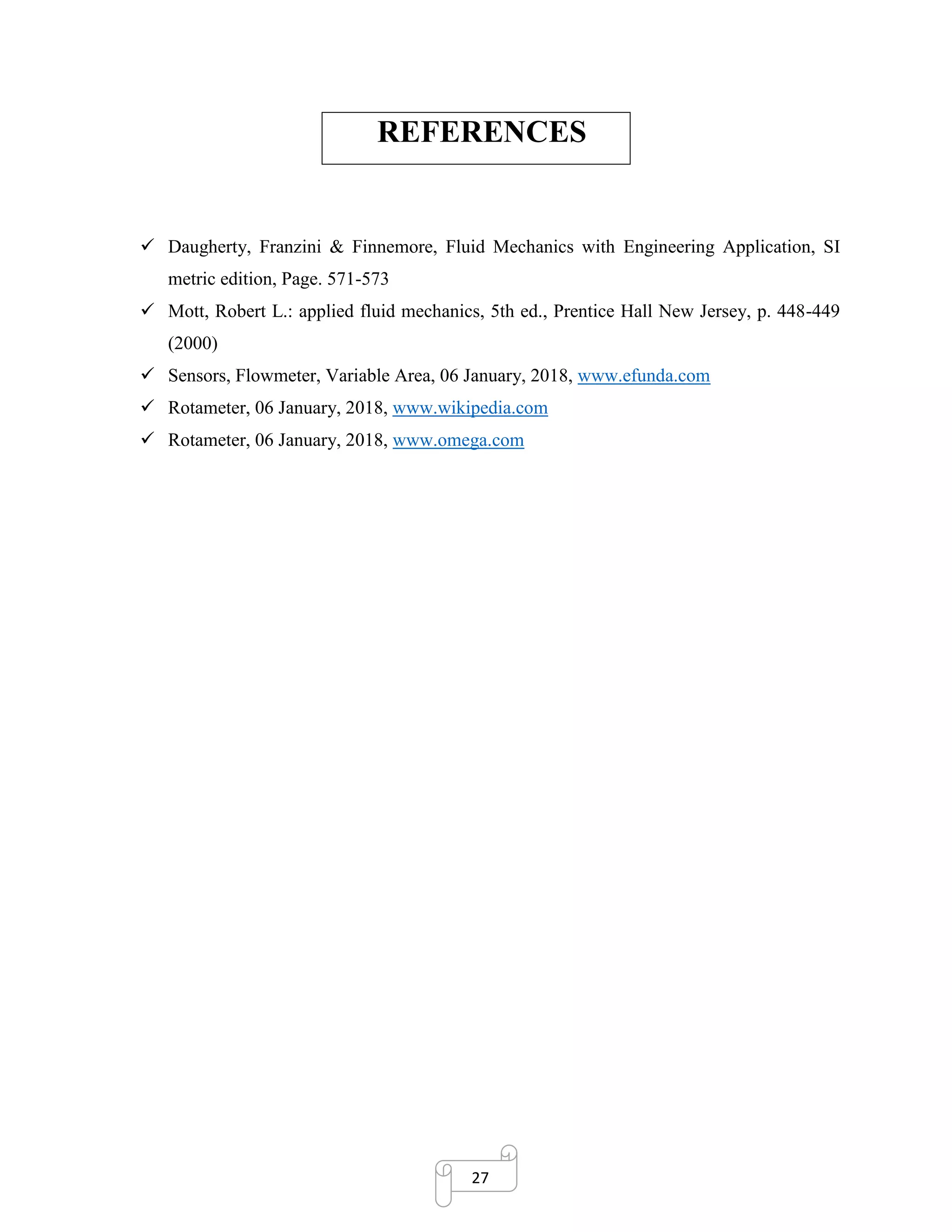

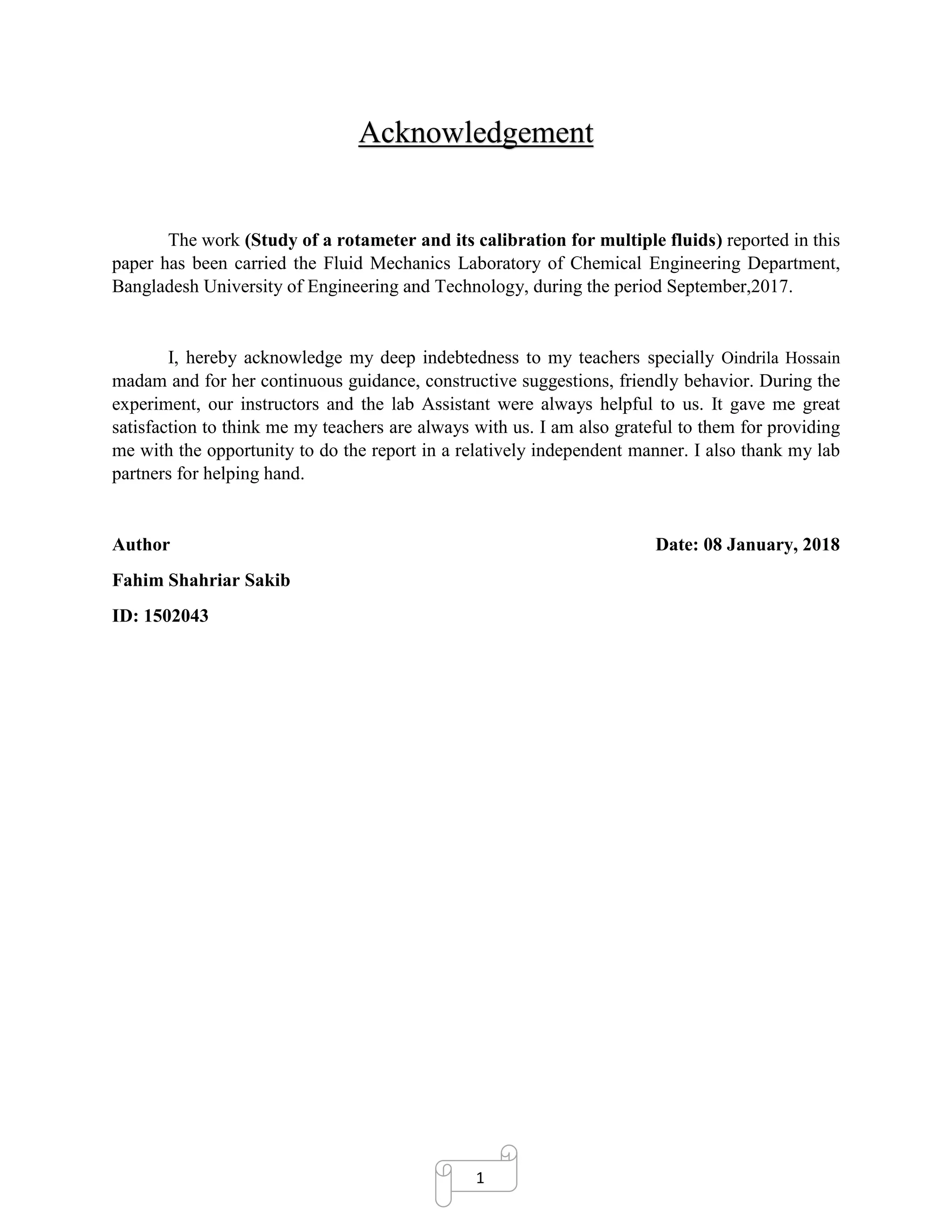

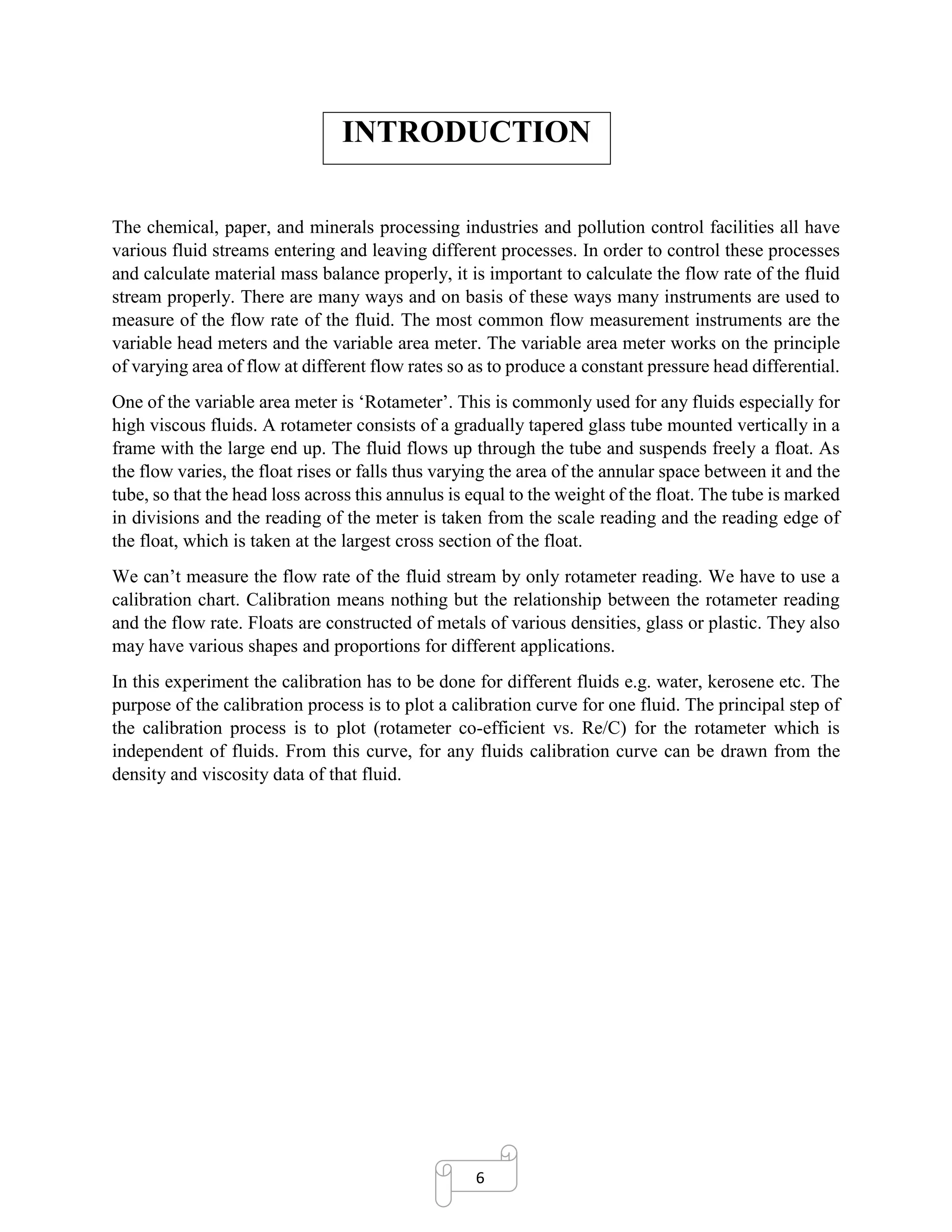

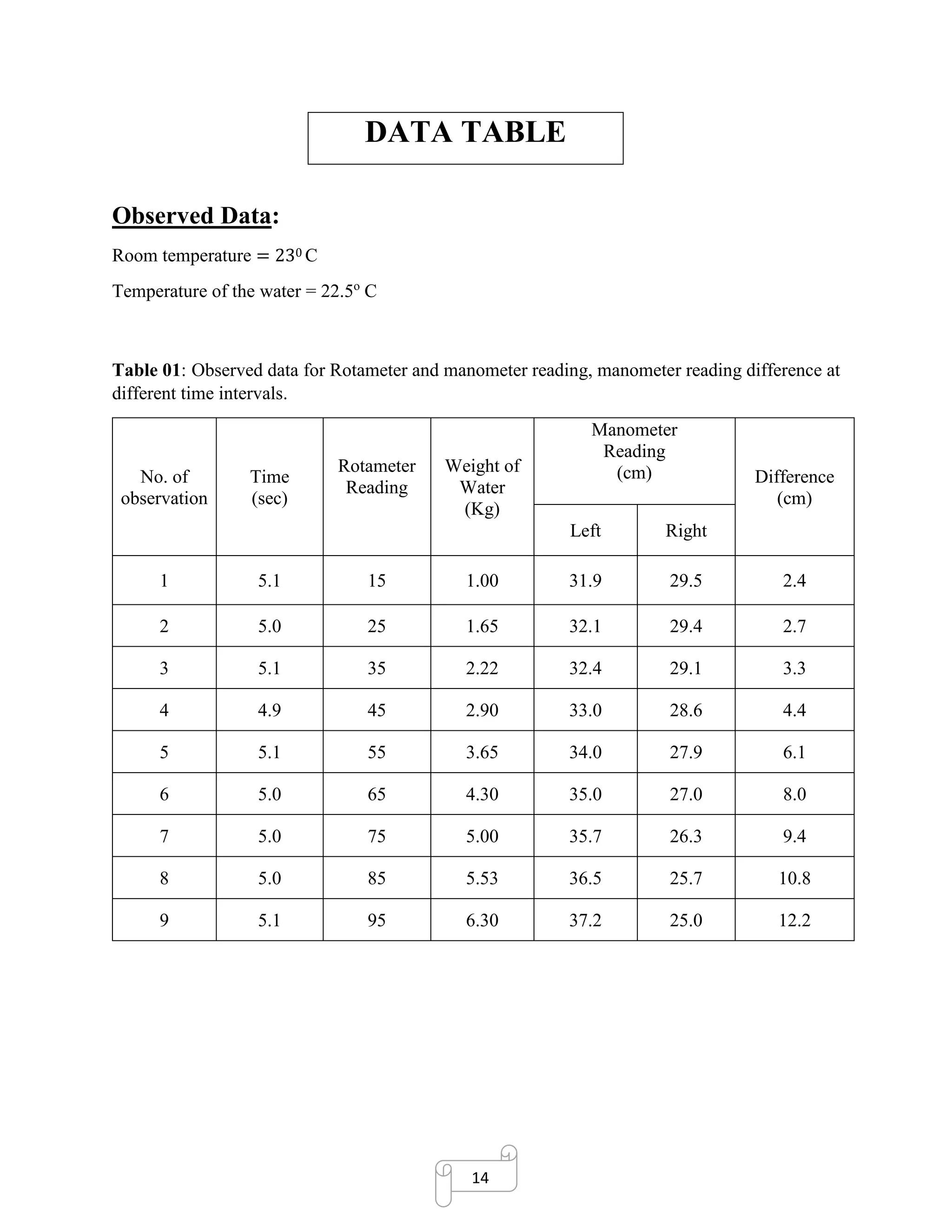

SAMPLE CALCULATION

Sample calculation for the ninth (8th

) observation is given below:

Flow Rates Calculation:

▪ Mass of empty bucket as reference

▪ Mass of water, m = 5.53kg

▪ Time, t = 5.00 s

▪ Mass flow rate, M =

5.53 𝑘𝑔

5.00 𝑠

= 1.11 kg / s

▪ Density of the water at 22.50

C ρw = 997.6 kg/m3

▪ Volumetric flow rate, Qw =

𝑚

=

1.11

997.6

m3

/s = 11.09 × 10-4

m3

/s

Calculation of Rotameter Data:

✓ Diameter of rotameter tube at lower end, D1= 1.5 inch = (1.5 × 0.0254) = 0.0381 m

✓ Diameter of rotameter tube at upper end, D2= 2.0 inch = (2.0 × 0.0254) = 0.0508 m

✓ Maximum float diameter, Df= 1.5 inch= 3.81×10-2

m

✓ Volume of the float, Vf= 1.077×10-3

ft3

= [(1.077 × 10−3)𝑓𝑡3

× 0.0283

𝑚3

𝑓𝑡3

]

= 3.05×10-5

m3

✓ Density of the float, ρf = 486.93 lbm/ft3

= [(486.93

𝑙𝑏 𝑚

𝑓𝑡3

× 0.4536

𝑘𝑔

𝑙𝑏 𝑚

) ÷ 0.0283

𝑚3

𝑓𝑡3

]

=7804.64 kg/m3

✓ Area of the float, Af =

Df

2

4

=

3.1416 x (0.0381)2

4

= 1.14 × 10-3

m2

✓ Diameter of rotameter tube at the maximum cross section of float,

Dt = D1 + (D2 − D1) ×

R

100

= 0.0381 + (0.0508 − 0.0381) ×

85

100

m = 0.0489 m

✓ Annulus cross sectional area between float and tube, Ao =

(𝐷𝑡

2

−𝐷 𝑓

2

)

4

=

4

× [(0.0489)2

− (0.0381)2

] = 7.38 × 10-4

m2

✓ Equivalent diameter, Deq = Dt - Df = (0.0489 − 0.0381) = 0.0108 m](https://image.slidesharecdn.com/rotametercalibrationreportformultiplefluids-180107123335/75/Rotameter-calibration-report-for-multiple-fluids-18-2048.jpg)

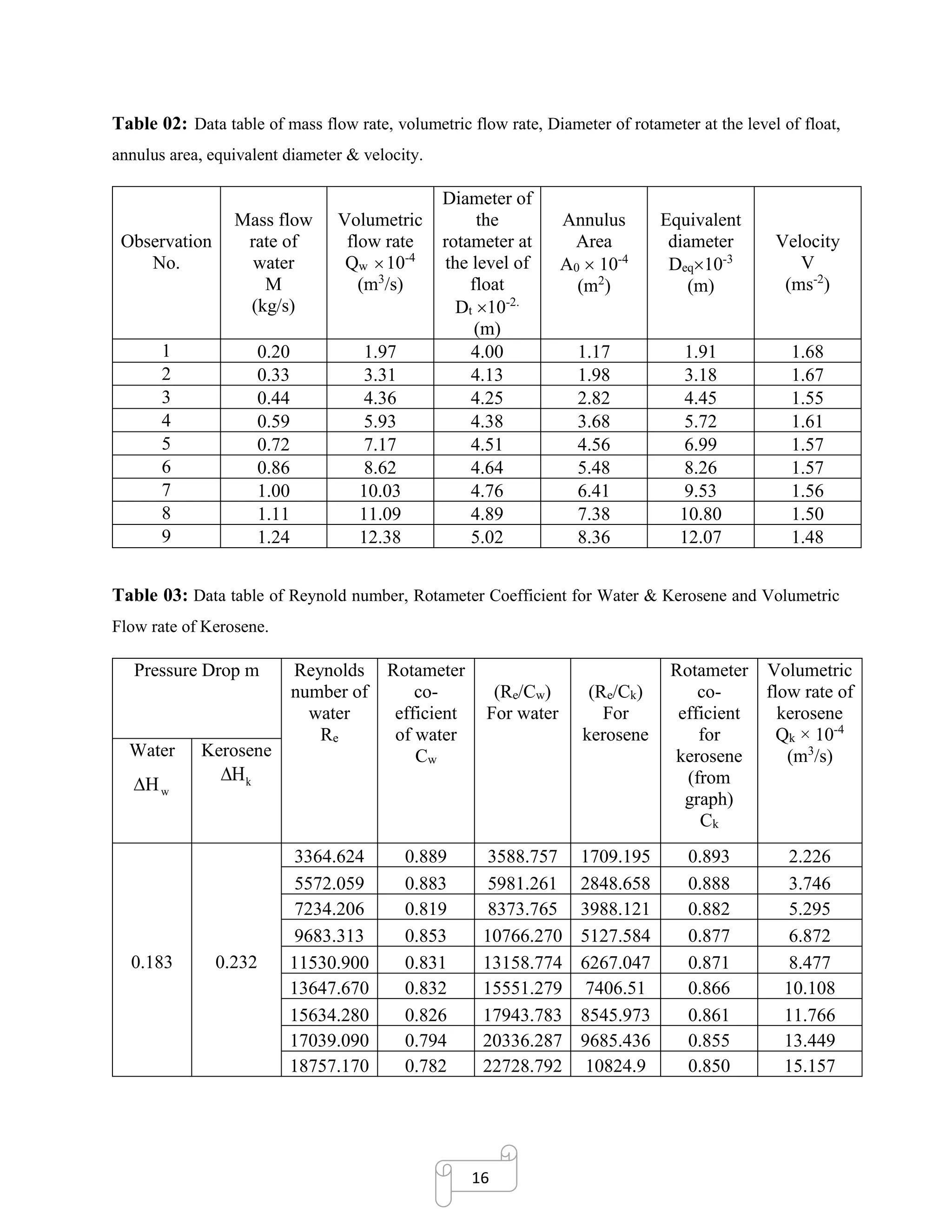

![18

Calculation of Rotameter Co-efficient for Water:

➢ Net head loss across the annulus, Hw = Vf (

𝑓− 𝑤

𝐴 𝑓 𝑤

)

= [3.05 × 10−5

(

7804.64−997.6

1.14×10−3×997.6

)] = 0.1826 m

➢ Rotameter co-efficient for water, Cw =

𝑄 𝑤

𝐴 𝑜√2𝑔 𝐻 𝑤

=

11.09 × 10−4

8.36𝑥10−4√2×9.8×0.1826

= 0.794

➢ Viscosity of water, µw = 8.96×10-4

Ns/m-2

[By interpolation (Ref: Daugherty, Franzini & Finnemore, Fluid

Mechanics with Engineering Application, SI metric edition, Page-591)]

From equation (4)

• Re/C = 𝐷𝑒𝑞

√2𝑔 𝐻 = 10.80 × 10−3

×

997.6

8.96×10−4

× √2 × 9.81 × 0.1826 = 20336.287

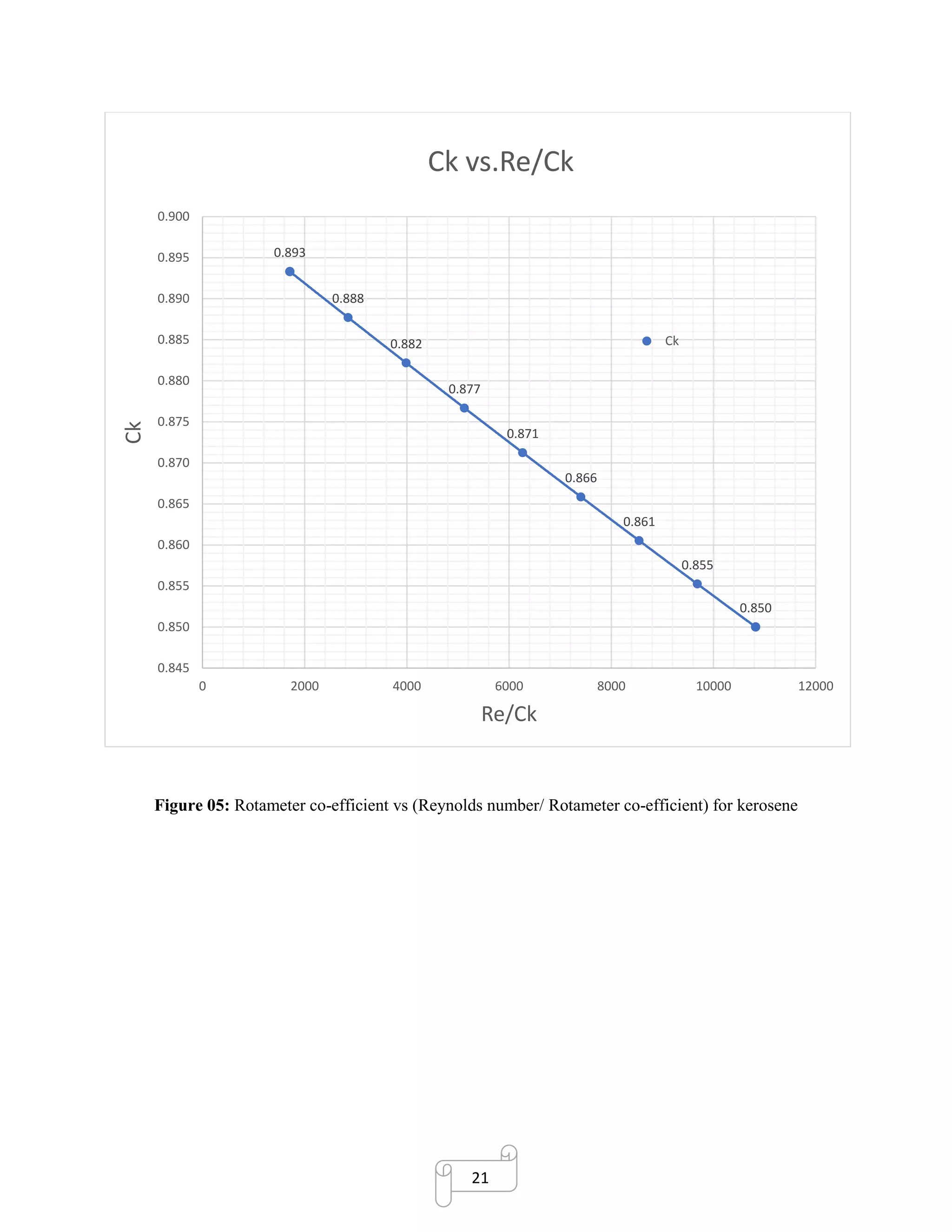

Calculation of Rotameter Co-efficient for Kerosene:

At 200

C

Density of kerosene ρk= 808 kg/m3

Viscosity of kerosene µk = 1.92×10-3

Ns/m2

[Ref: Daugherty, Franzini & Finnemore,

Fluid Mechanics with Engineering

Application, SI metric edition, Page-573]

➢ Net head loss across the annulus, Hk = Vf (

𝑓− 𝑘

𝐴 𝑓 𝑘

) = [3.05 × 10−5

(

7804.64−808

1.14×10−3×808

)]

= 0.232 m

• For Kerosene, Re/C = 𝐷𝑒𝑞

𝜌 𝑘

√2𝑔𝐻 = 10.80 × 10−3

×

808

1.92×10−3

× √2 × 9.81 × 0.232

= 9685.436

From Figure 04, the value of rotameter coefficient for Kerosene, Ck= 0.855 when Re/C = 9685.436](https://image.slidesharecdn.com/rotametercalibrationreportformultiplefluids-180107123335/75/Rotameter-calibration-report-for-multiple-fluids-19-2048.jpg)

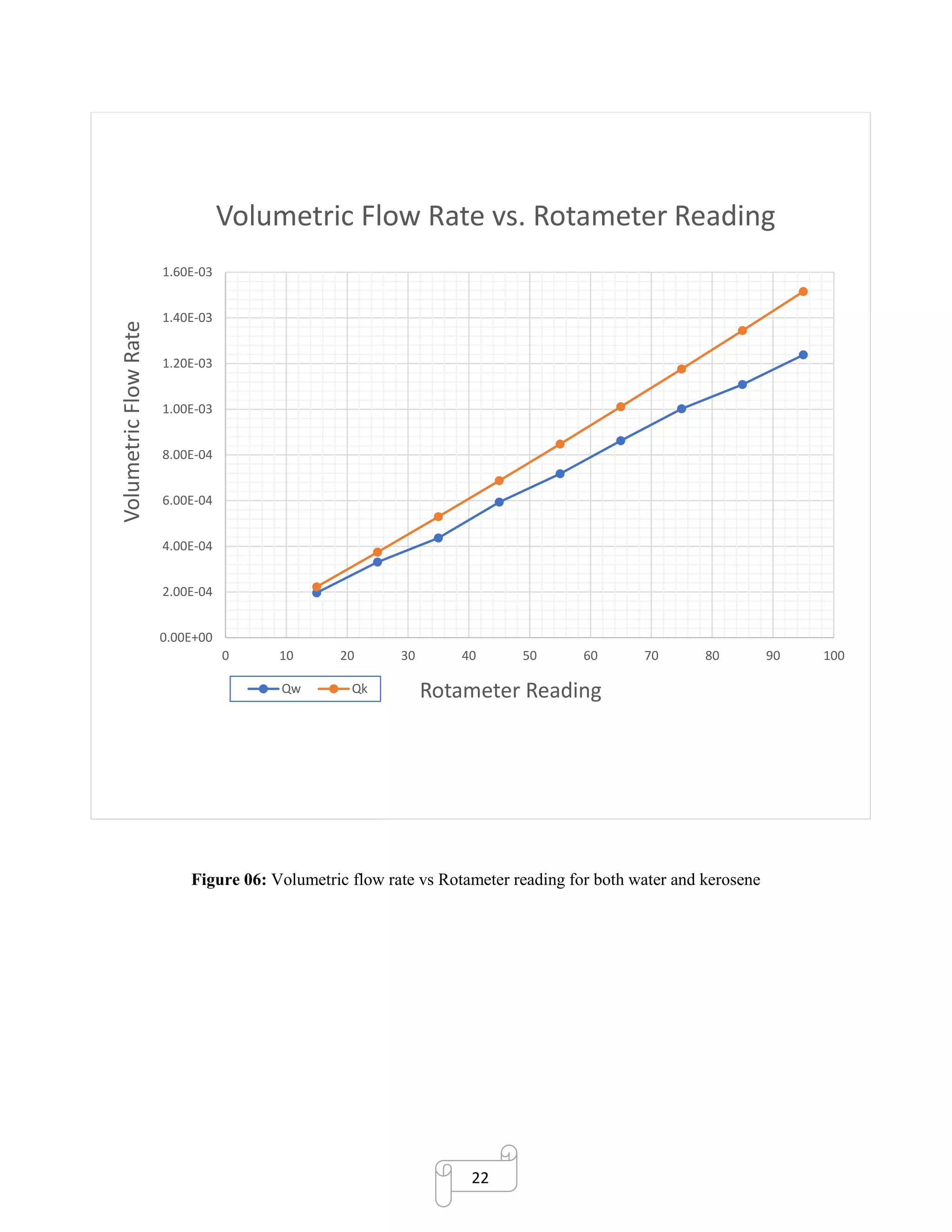

![19

Calculation for Volumetric Flow Rate for Kerosene:

𝑄 𝑘

𝑄 𝑤

=

𝐶 𝑘√ 𝐻 𝑘

𝐶 𝑤√ 𝐻 𝑤

Qk = Qw ×

𝐶 𝑘√ 𝐻 𝑘

𝐶 𝑤√ 𝐻 𝑤

= 12.38 x 10-4

×

0.855√0.2321

0.794√0.1824

= 13.449 × 10-4

m3

/s

Calculation of Experimental Pressure Drop:

Density of Mercury at 200

C, Hg = 13550 kg/m3

[Ref: Daugherty, Franzini & Finnemore,

Fluid Mechanics with Engineering

Application, SI metric edition, Page-573]

➢ Experimental pressure drops, P = R (

𝐻𝑔− 𝑤

𝑤

) = 0.108 x (

13550−997.6

997.6

)

= 1.359 m](https://image.slidesharecdn.com/rotametercalibrationreportformultiplefluids-180107123335/75/Rotameter-calibration-report-for-multiple-fluids-20-2048.jpg)