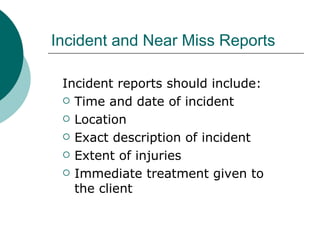

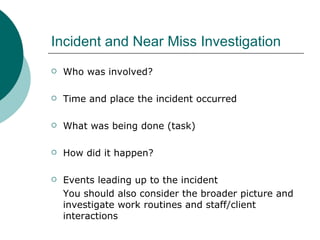

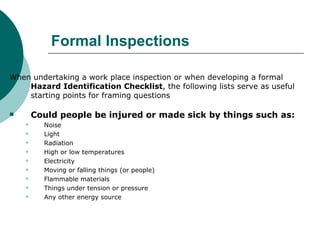

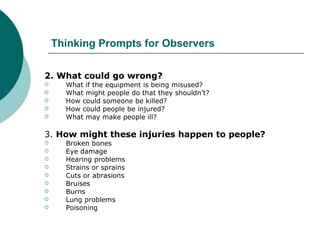

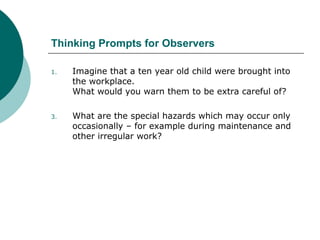

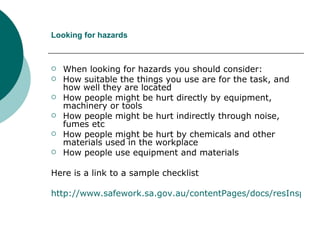

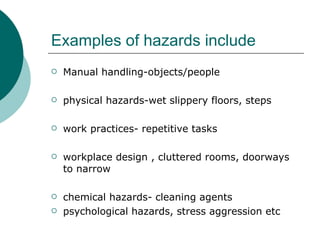

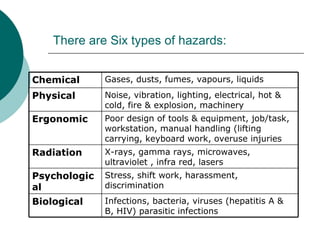

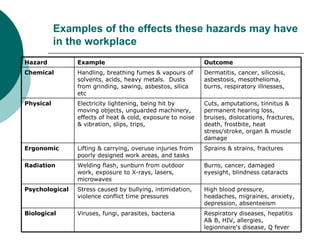

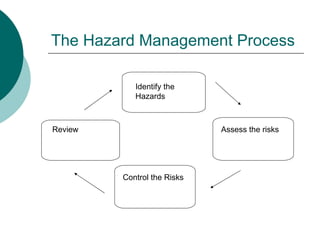

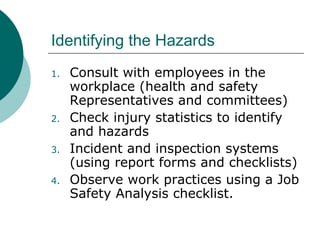

This document discusses identifying workplace hazards. It defines a hazard as something with potential to cause harm and provides examples such as manual handling, slippery floors, repetitive tasks, poorly designed workspaces, chemicals, stress, and radiation. There are six main types of hazards: biological, psychological, radiation, ergonomic, physical, and chemical. The key steps to hazard management are to identify hazards, assess risks, control risks, and regularly review the process. Hazards should be identified through consultation, injury statistics, incident reports, inspections, and job safety analyses.

![Injury Statistics These are useful as they help to identify patterns of injury and how they occurred. To review injury statistics for Aged Care Workers follow this link , click on WorkCover SA Statistical Review Part 1: 2005-06 [739KB] and refer to page 37. You may note that amongst the highest injuries for females over all industries is personal care assistant!!! Close behind is Registered Nurse, enrolled nurse and Aged persons carer!!!!](https://image.slidesharecdn.com/hazardmanv1-100217020345-phpapp01/85/Hazard-Manv1-10-320.jpg)