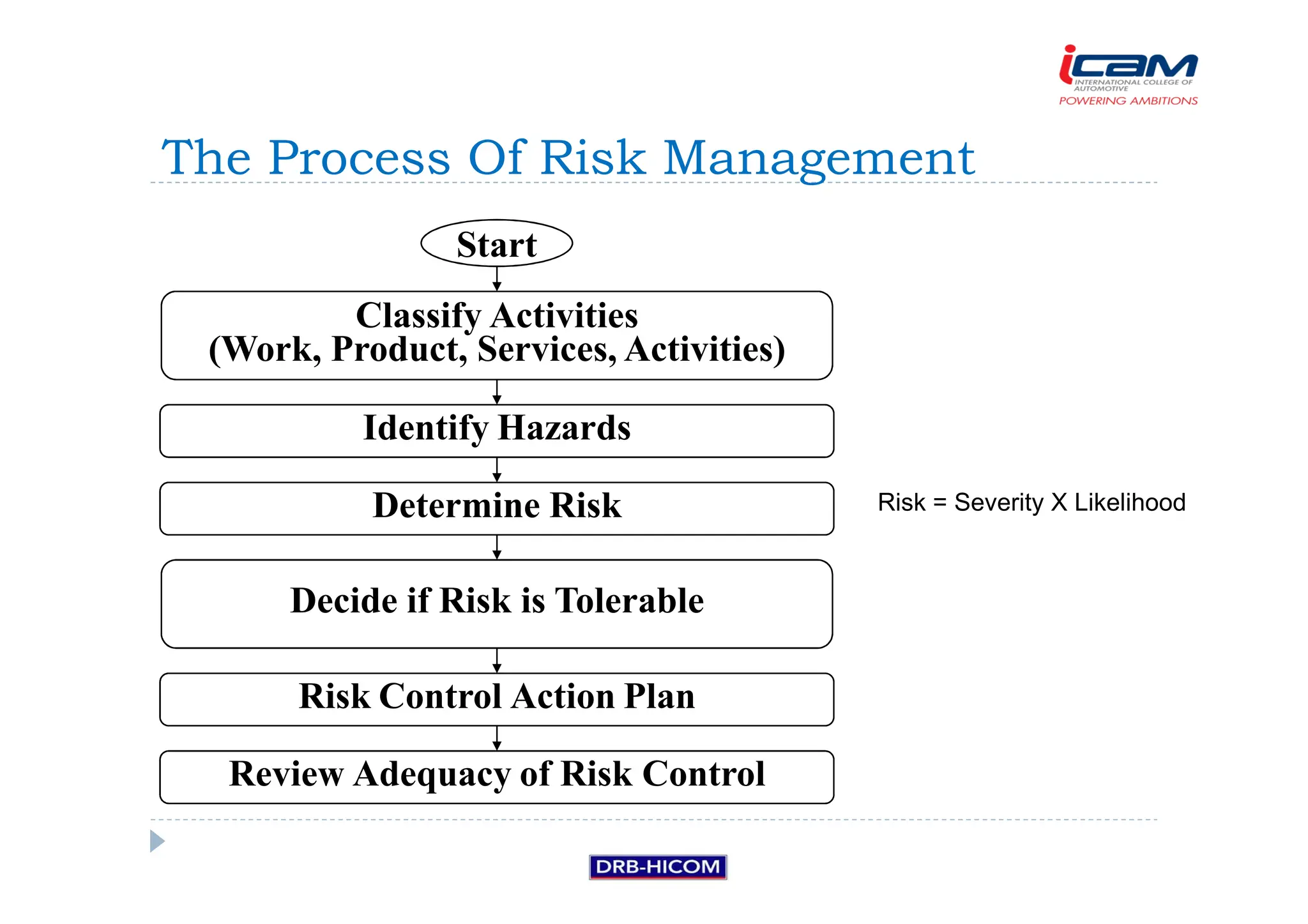

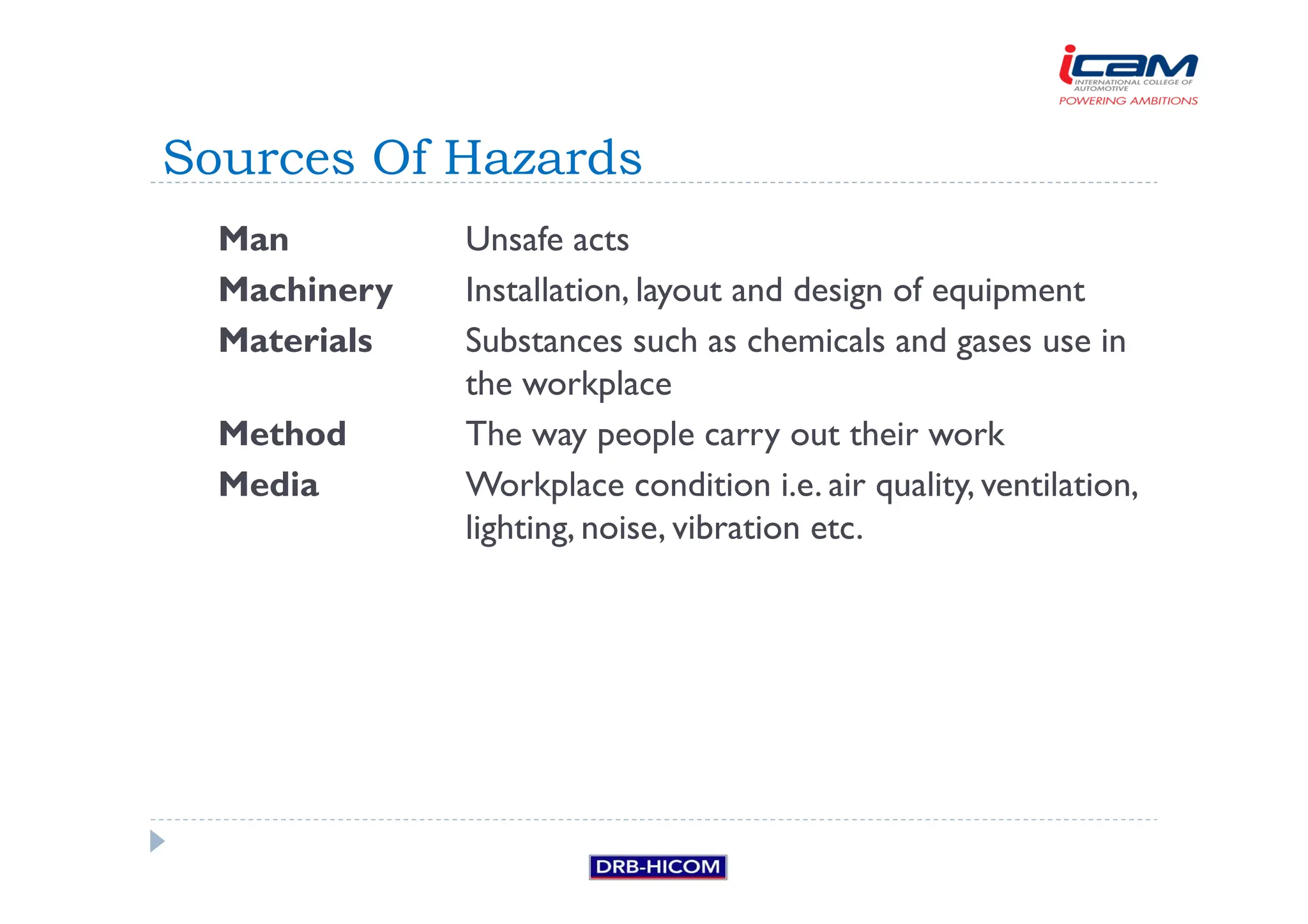

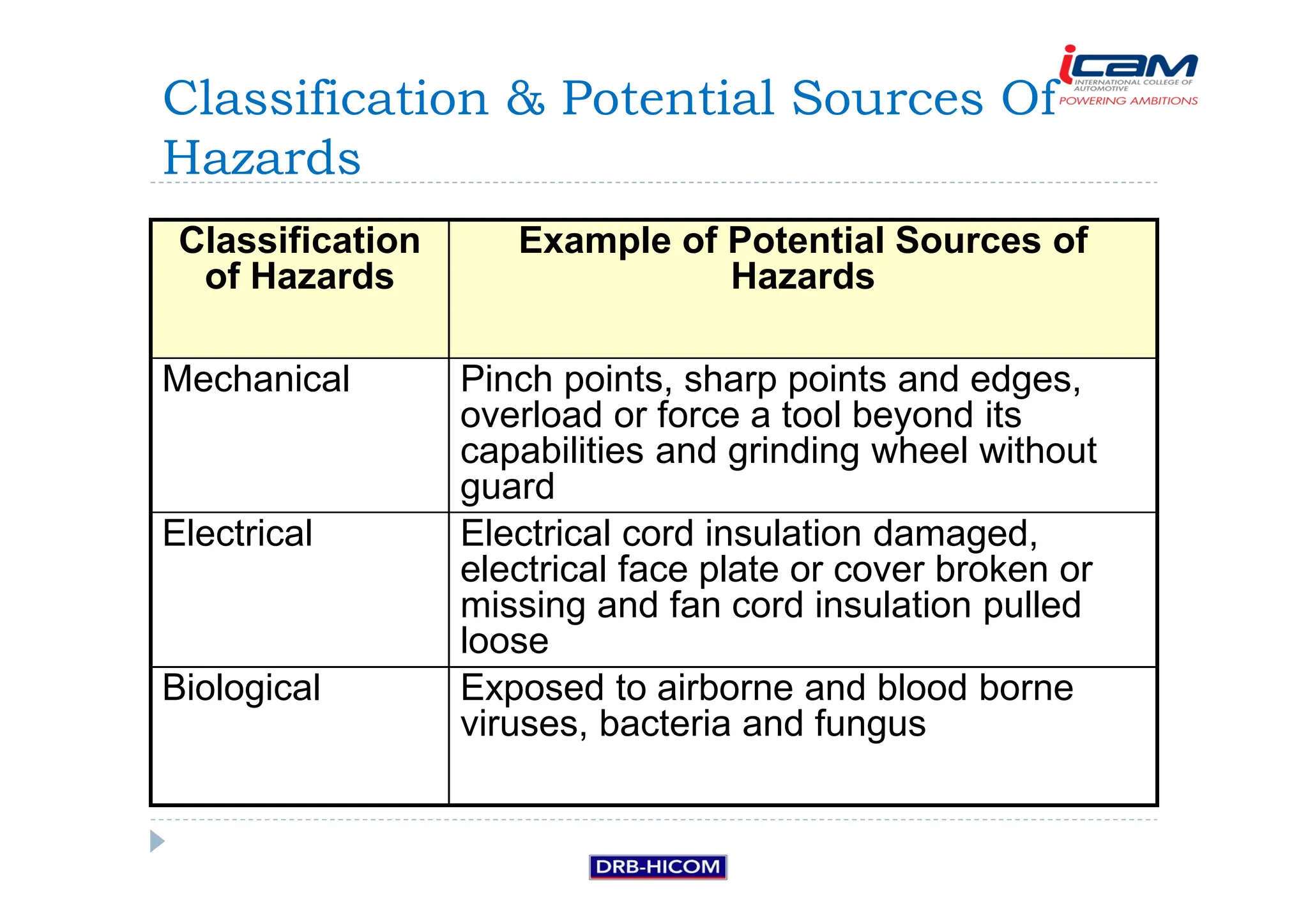

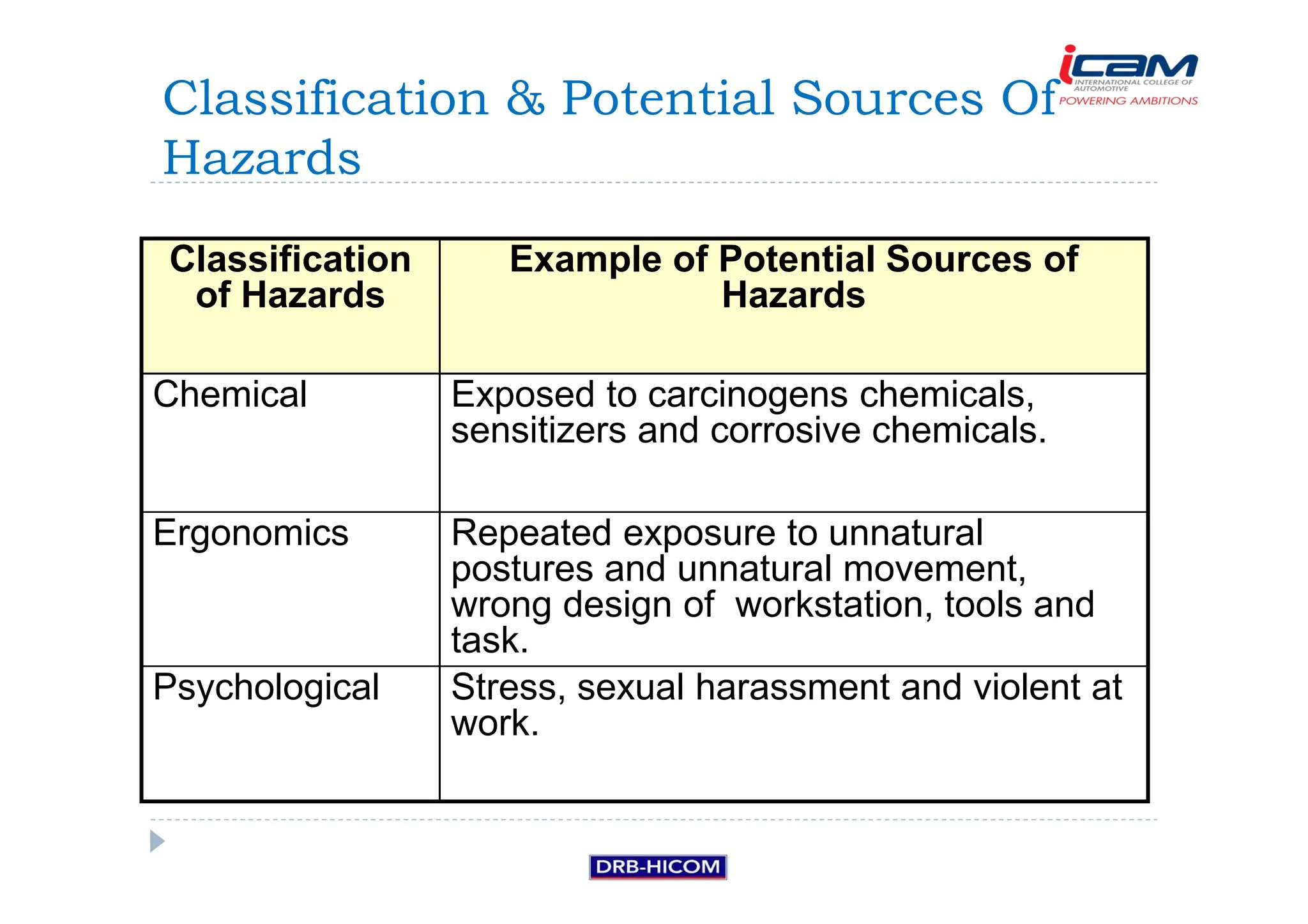

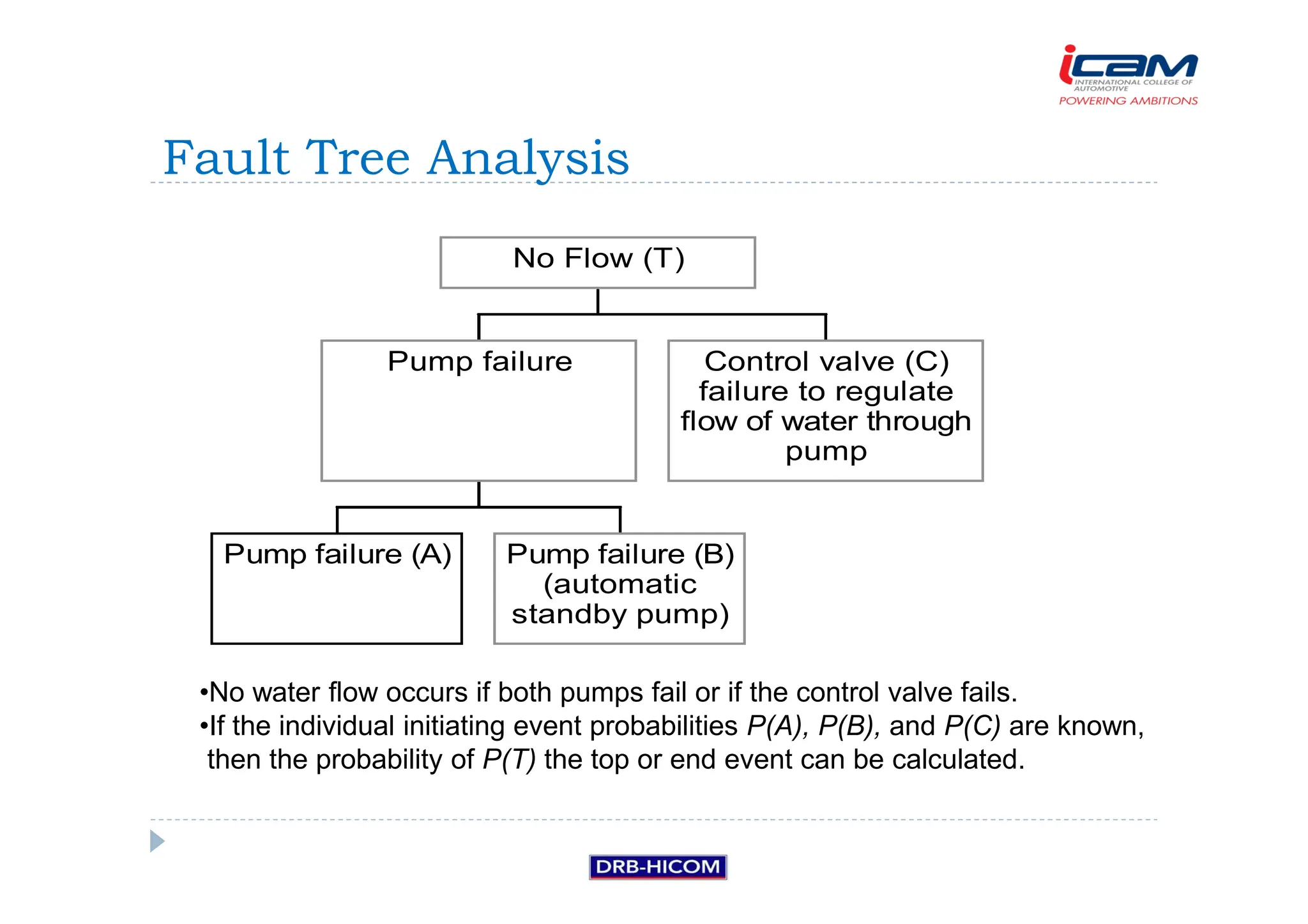

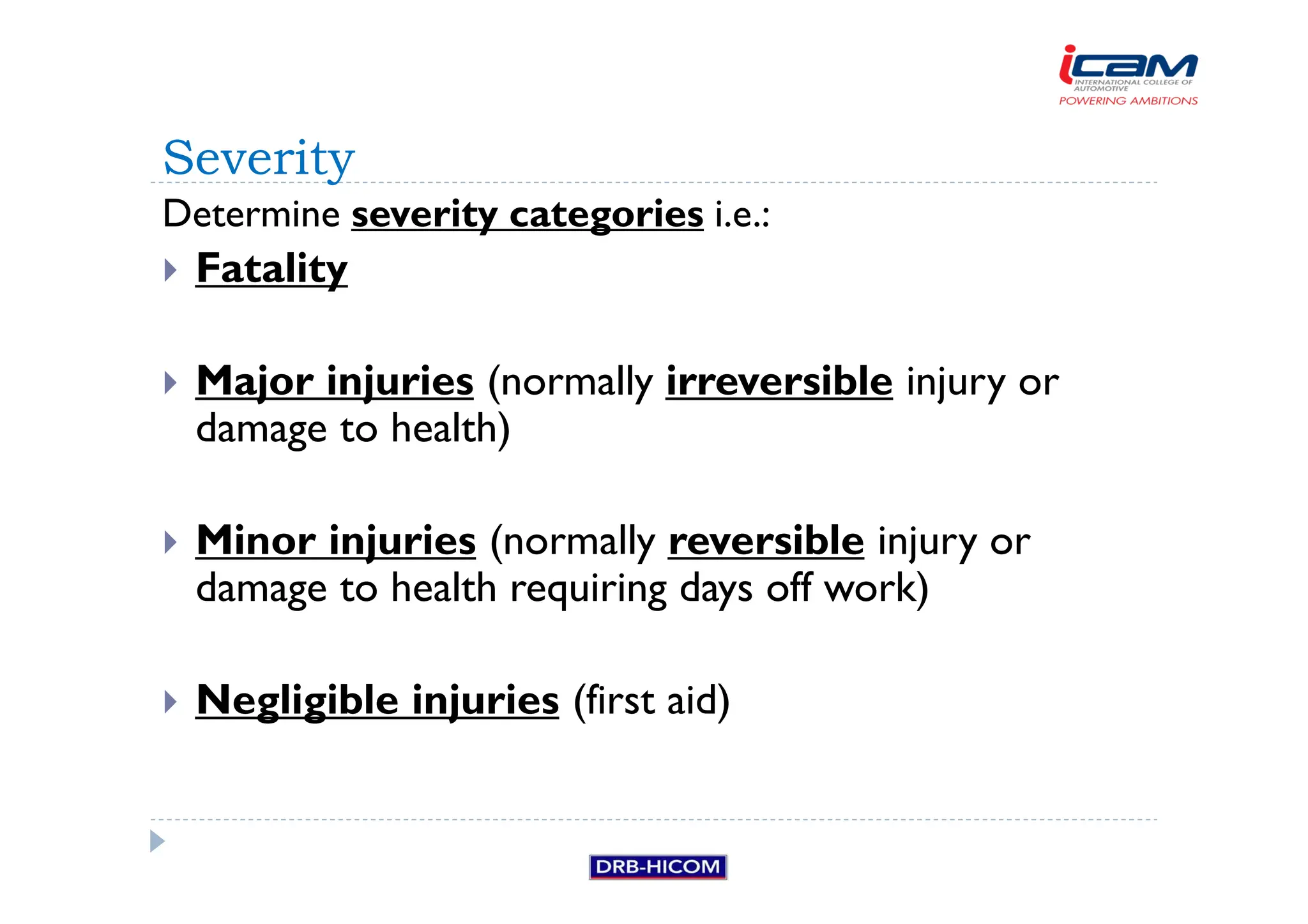

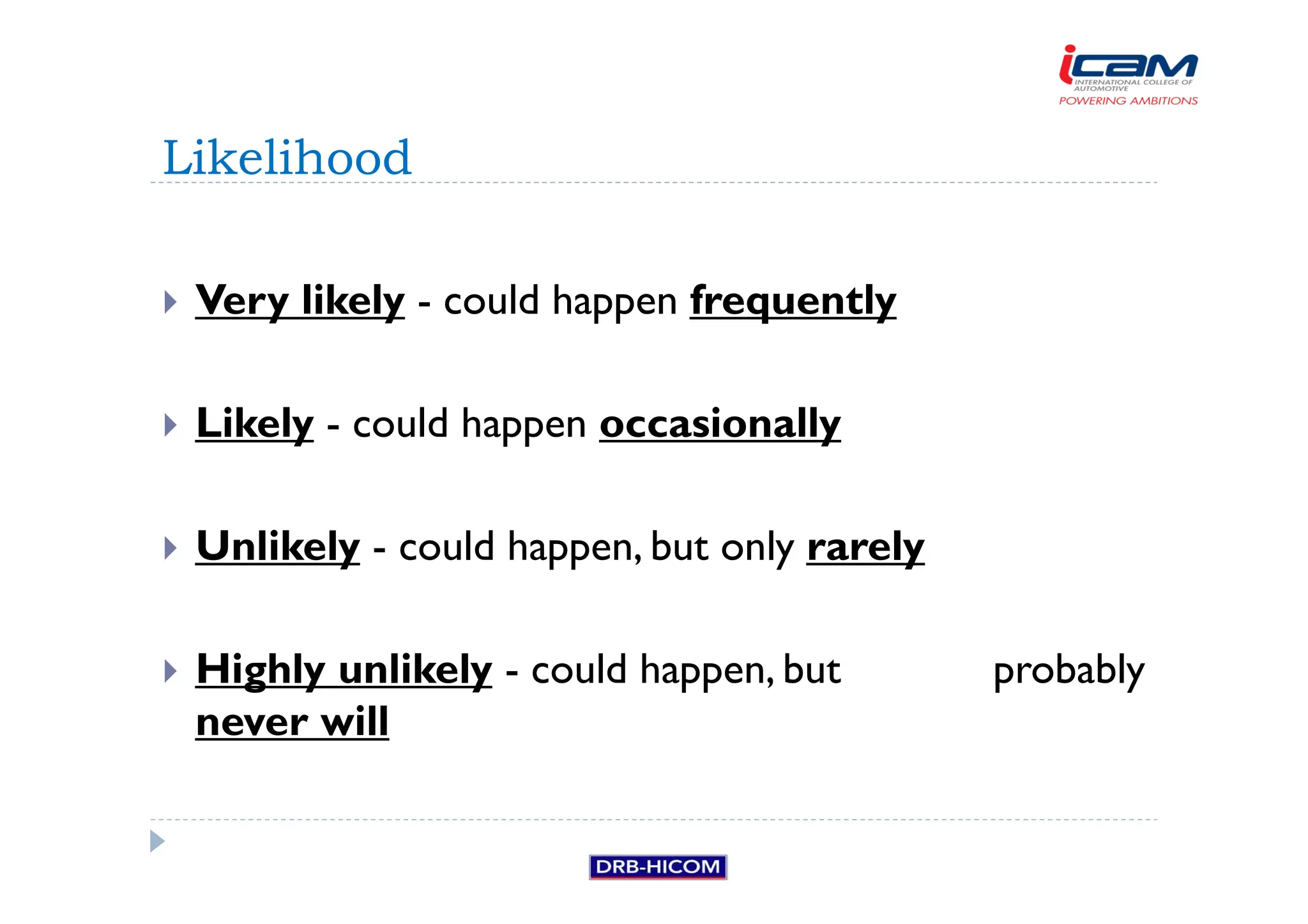

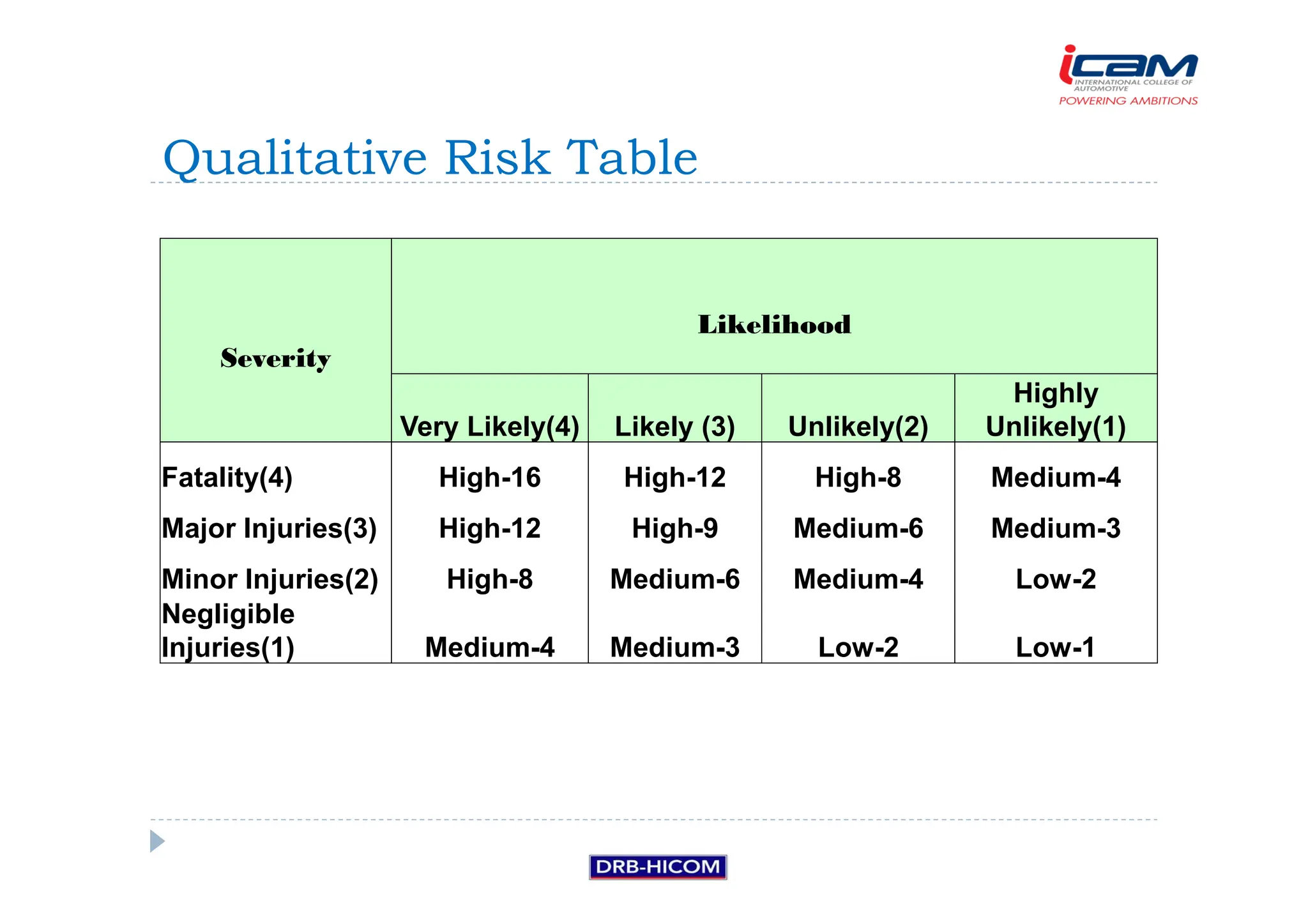

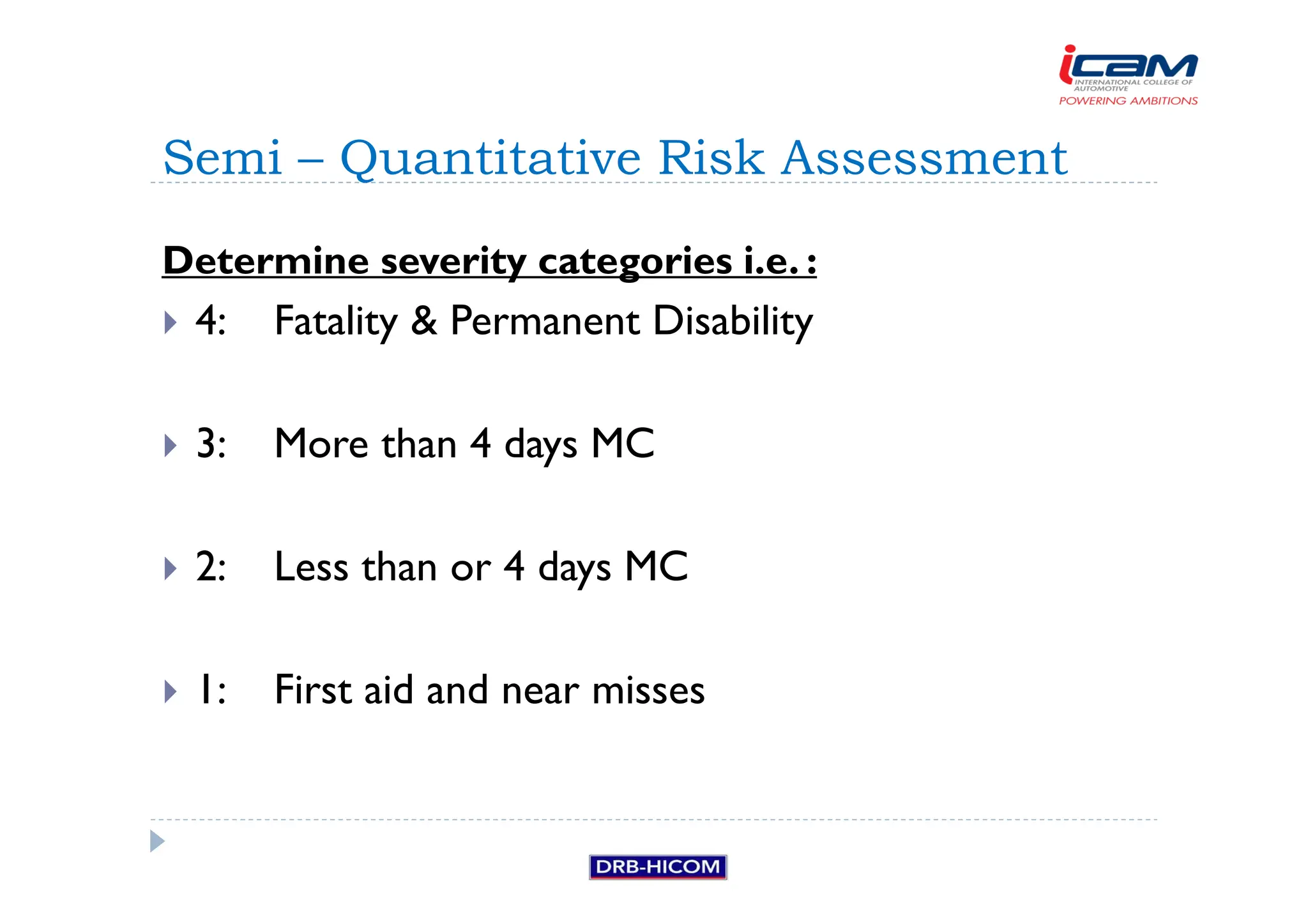

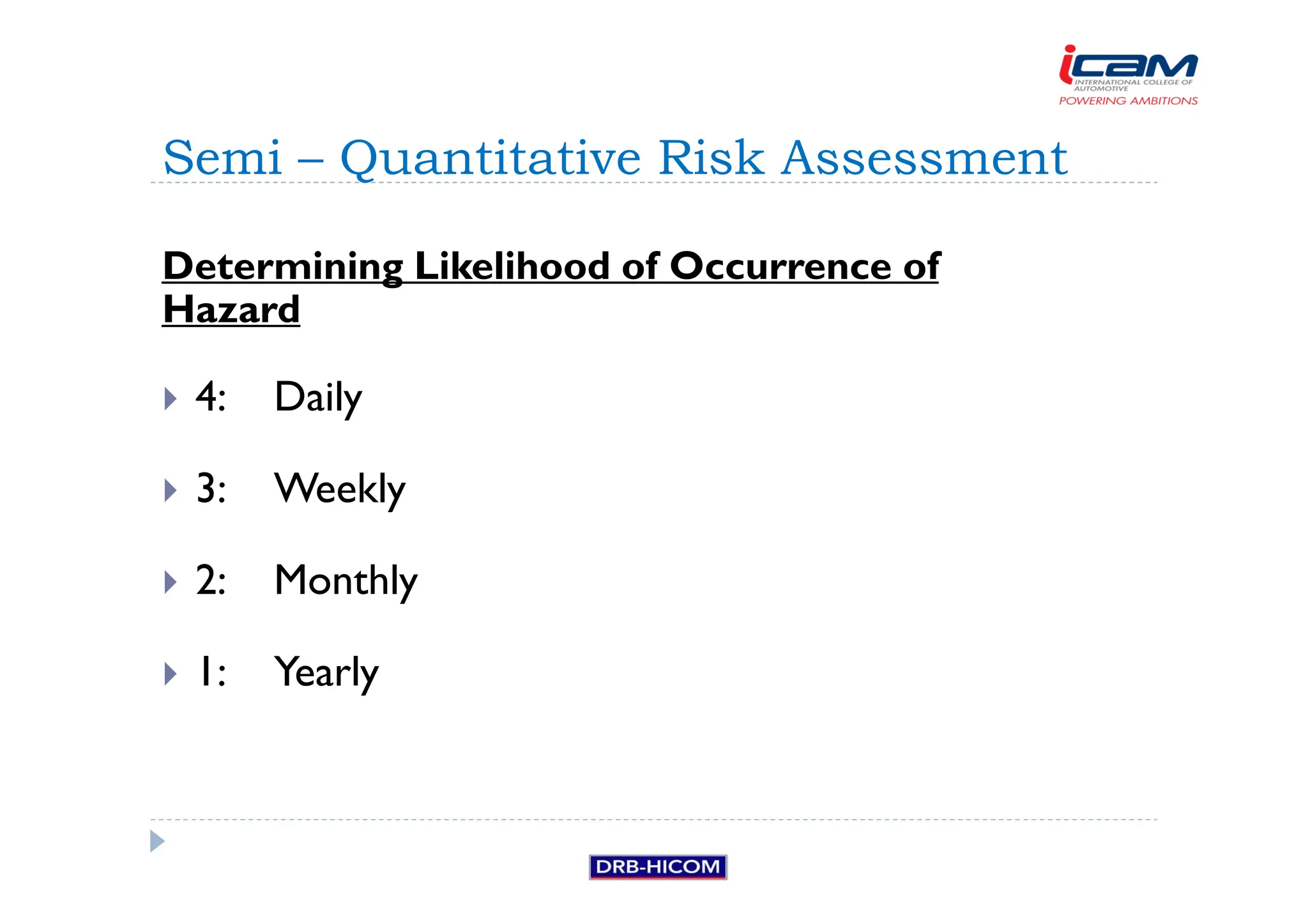

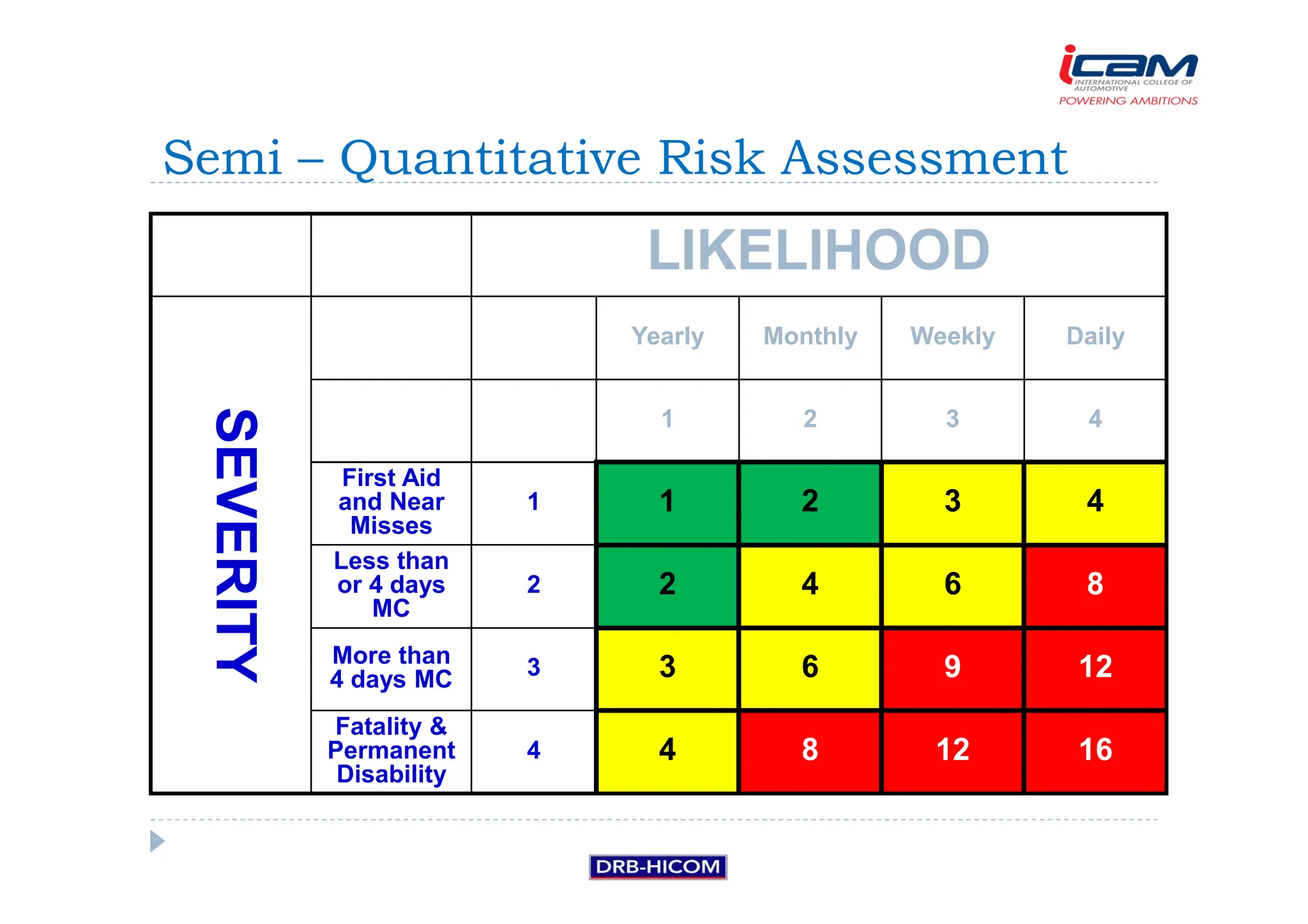

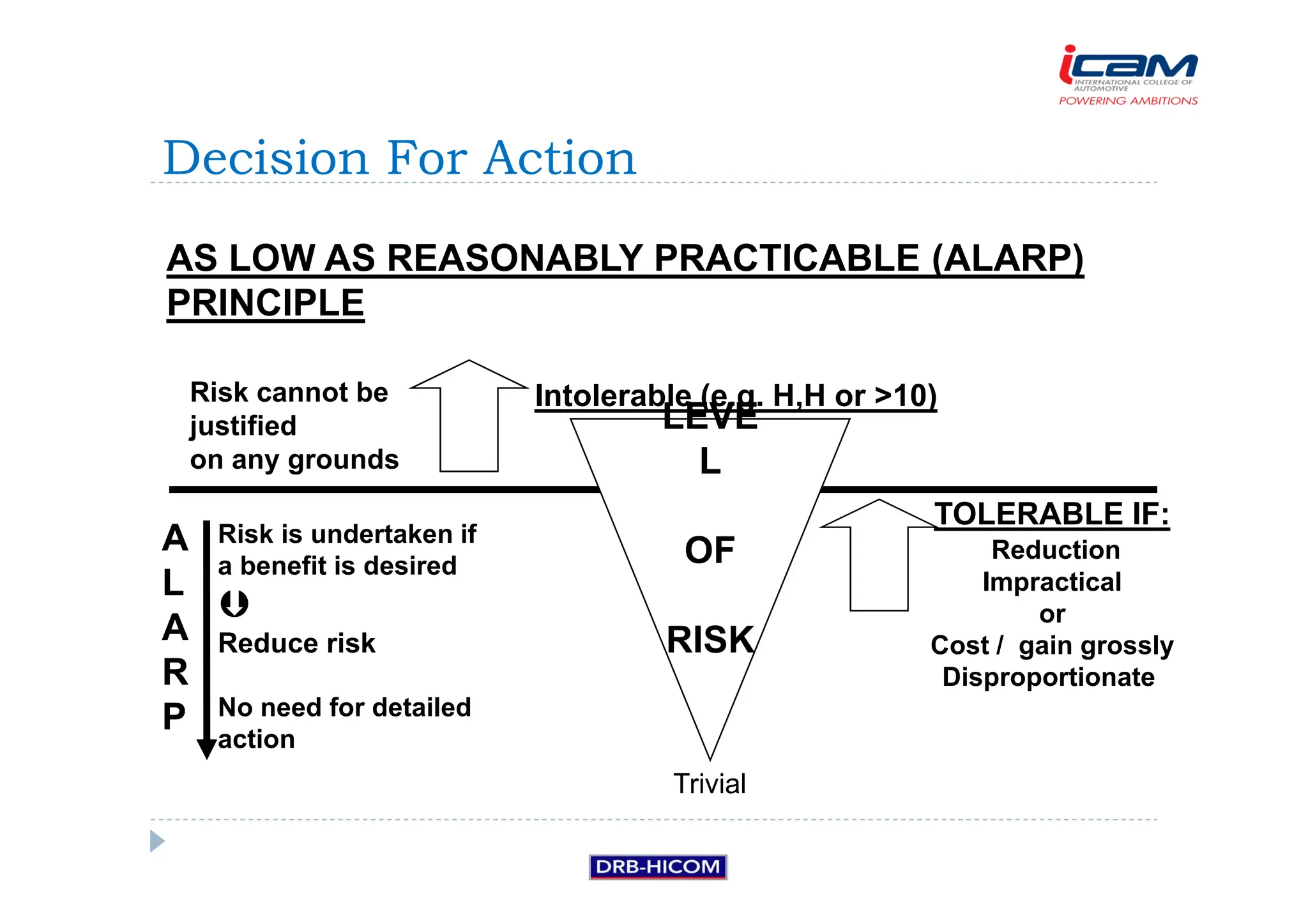

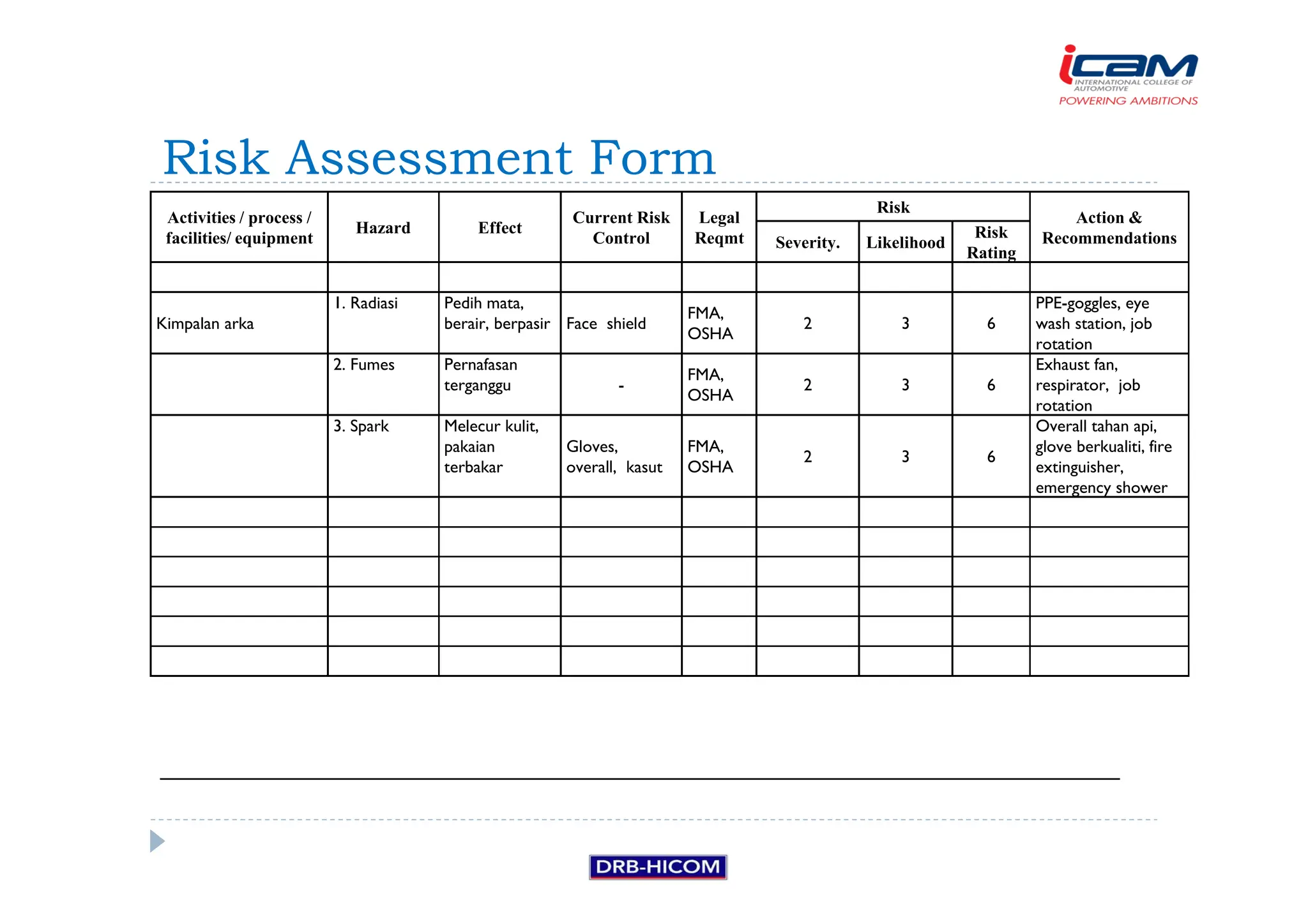

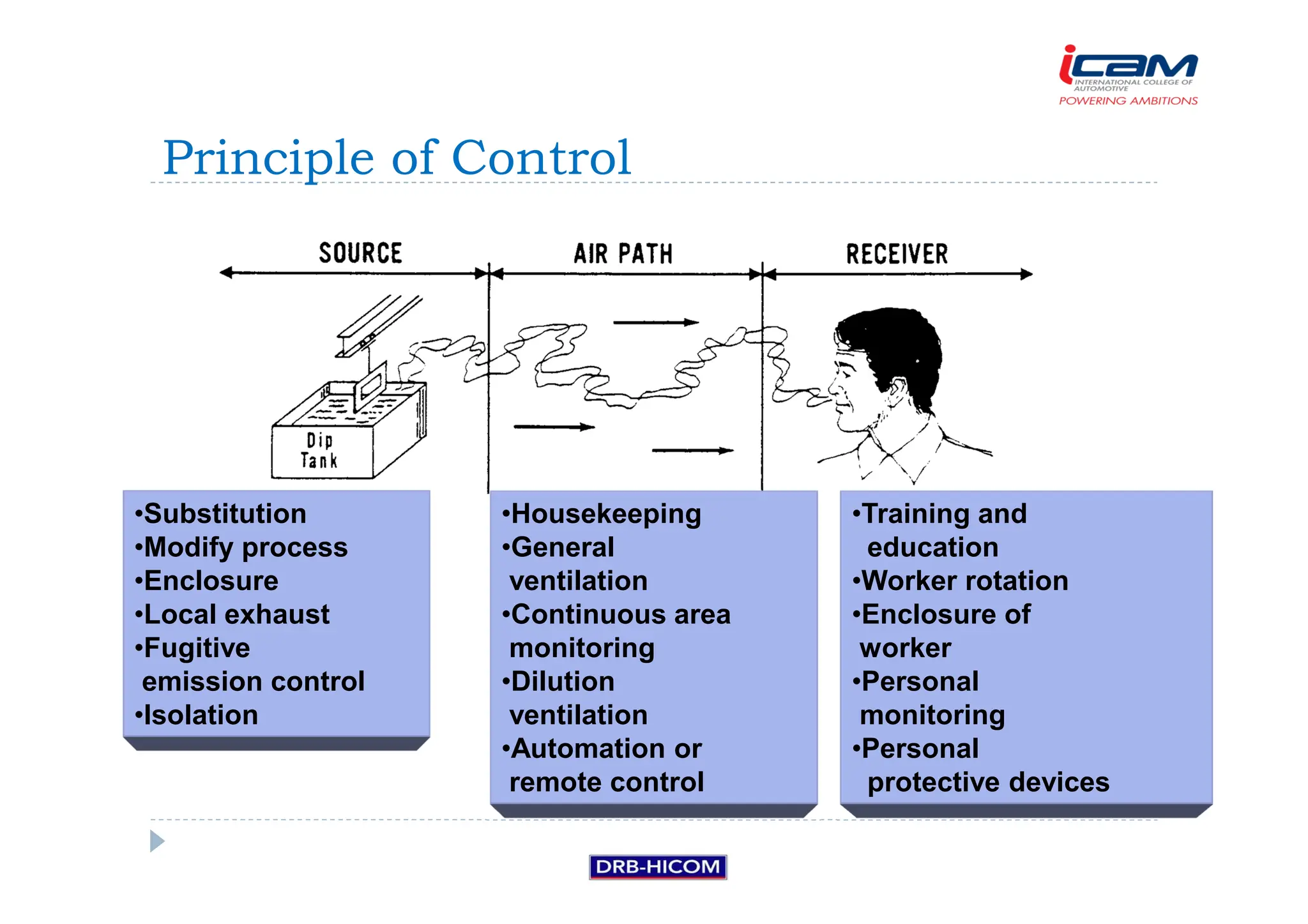

This document discusses hazard identification, risk assessment, and risk control (HIRARC). It defines key terms like hazard, risk, and danger. It describes the process of identifying hazards, assessing risks qualitatively or semi-quantitatively, and constructing a risk matrix. The document outlines when risk assessments should be carried out, who should be involved, and methods like job safety analysis, HAZOP, and fault tree analysis.