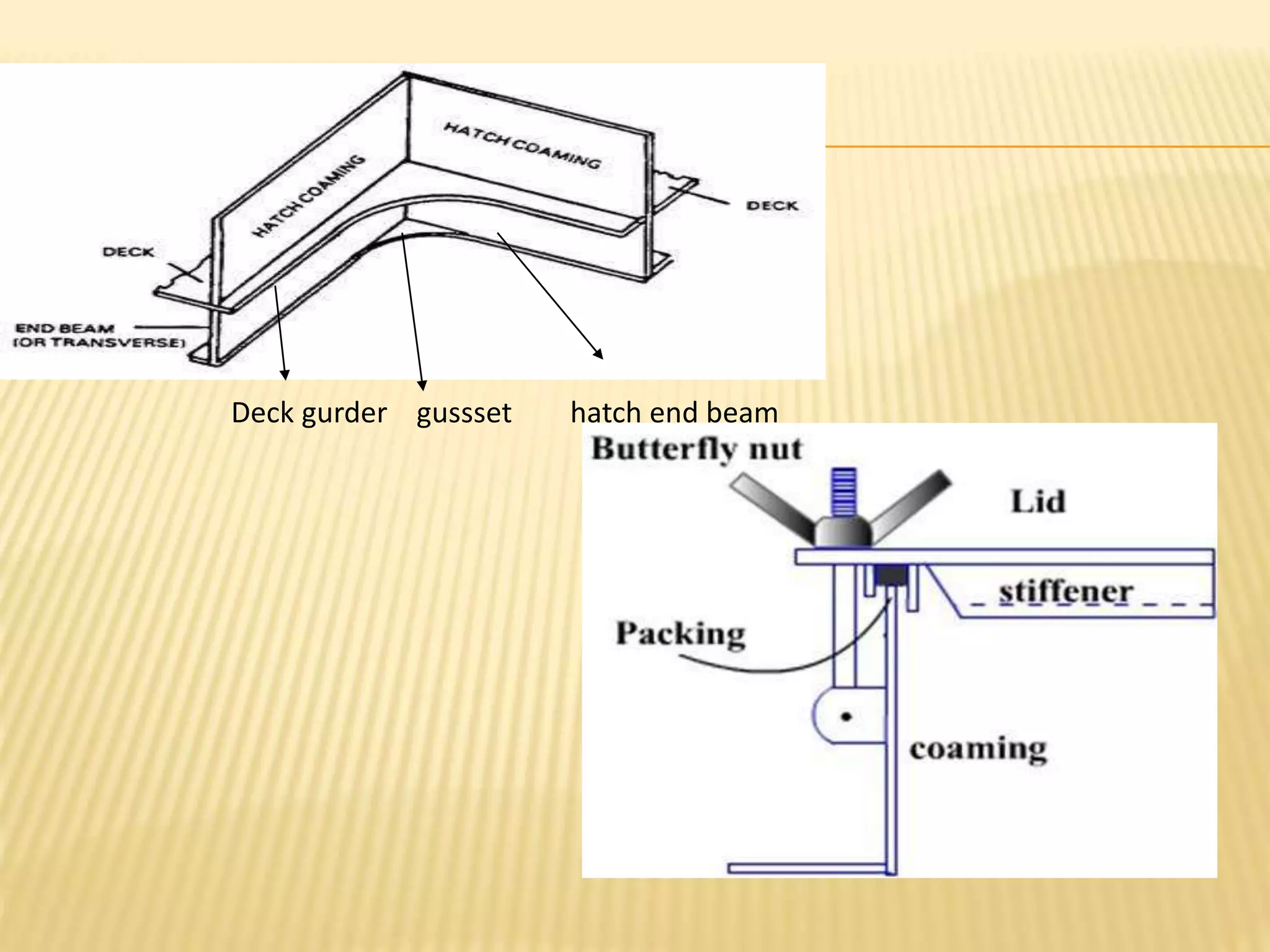

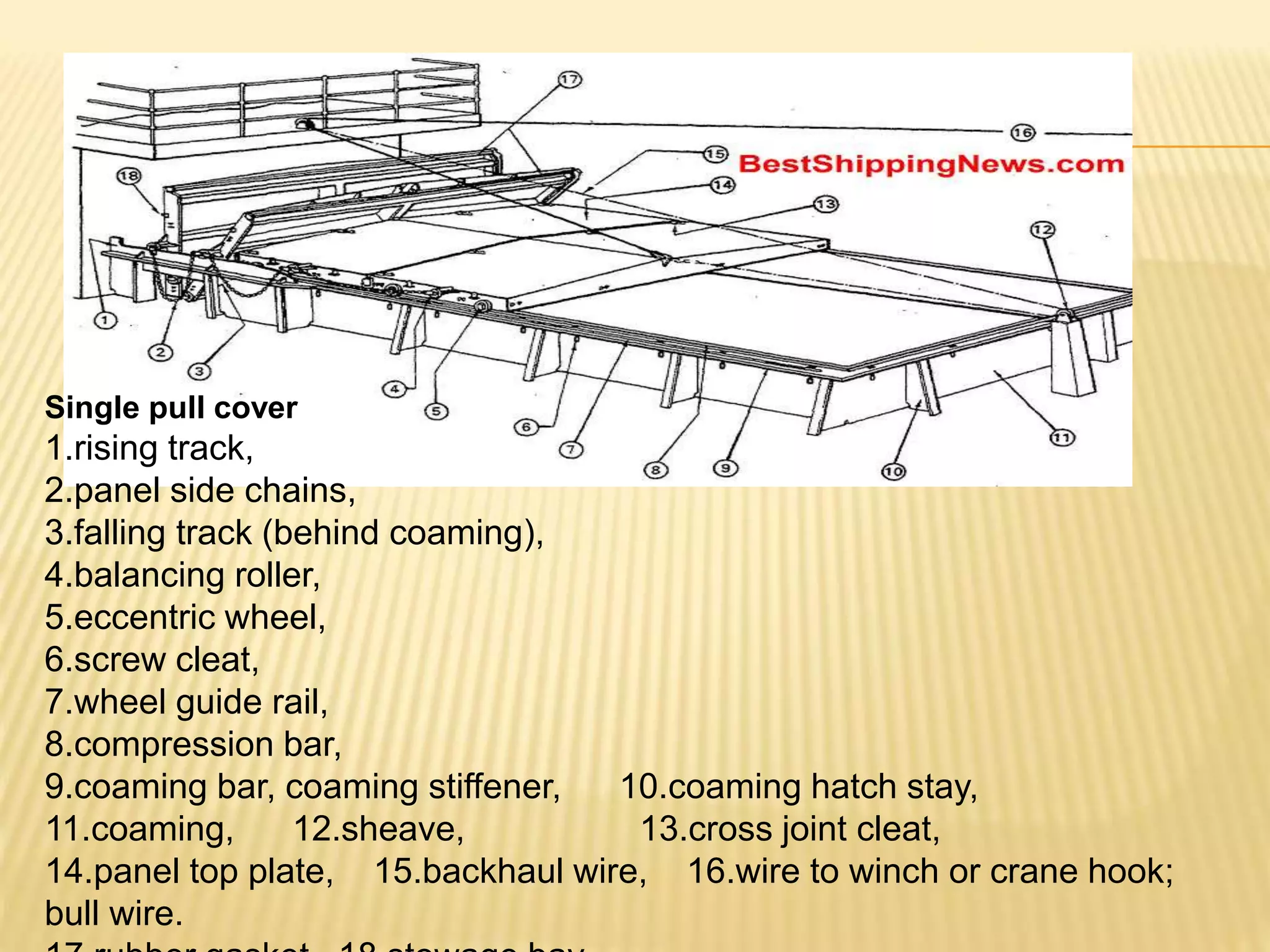

This document discusses hatchways on ships, including their purpose and positioning. Hatchways provide large openings in decks to allow access to cargo holds and storage rooms below. They are positioned either on exposed freeboard and superstructure decks forward of 0.25L or on exposed superstructure decks aft of 0.25L. Hatchways experience stress concentration at corners where large sections of deck plates and beams are cut out.