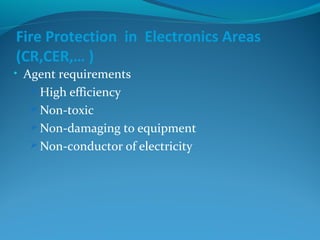

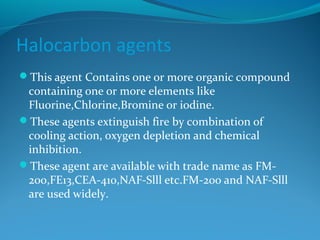

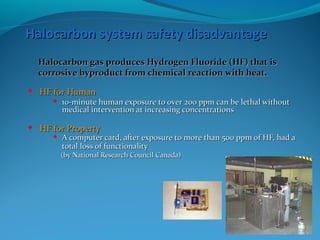

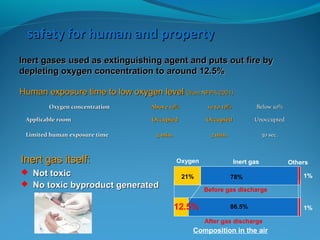

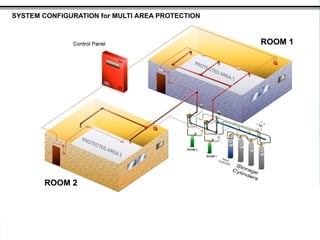

This document summarizes a presentation on inert gas extinguishing systems. It discusses the requirements for clean agents used in fire protection of electronics areas. It describes inert gases and halocarbon agents as the two categories of clean agents according to NFPA standards. Inert gases are preferred over halocarbon agents for their safety for humans and lack of toxic byproducts. The document outlines the operating principle of inert gas systems, which extinguish fires by diluting oxygen concentration below the level needed for combustion. It also discusses factors to consider in the design of inert gas systems, such as achieving the minimum design concentration. Overall, the presentation concludes that inert gas systems are better than halocarbon systems for fire protection due to their availability, ease of ref

![Pressure Relief Damper SizePressure Relief Damper Size

Pressure relief openings

During the flooding of a extinguishing zone with a gaseous extinguishing agent this

must be protected against positive pressure.

This is carried out with pressure relief openings. The same mass flow resp. flow rate

(density-dependent), which is brought into the room via the gas extinguishing system,

must to flow off through the opening.

A = 134 x Q / (P )½A = 134 x Q / (P )½

A: Calculated area of Pressure ReliefA: Calculated area of Pressure Relief

Damper [cm2]Damper [cm2]

Q: Maximum flow rate (= 1.6 x designQ: Maximum flow rate (= 1.6 x design

flow rate) [m3/min]flow rate) [m3/min]

P: Allowable strength of enclosureP: Allowable strength of enclosure

[Pa][Pa]](https://image.slidesharecdn.com/inertgaspresentation-160306224907/85/INERT-GAS-EXTINGUISHING-SYSTEM-14-320.jpg)