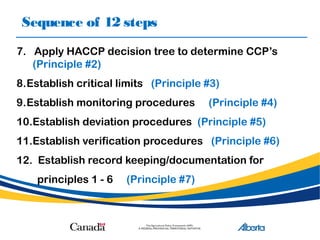

The document provides an introduction to Hazard Analysis Critical Control Point (HACCP) principles, emphasizing the importance of food safety and the roles of different stakeholders from producers to consumers. It outlines the identification, control, and prevention of physical, biological, and chemical hazards in food production through a systematic, science-based approach. The HACCP plan involves a 12-step process which includes assembling a team, analyzing hazards, establishing critical control points, and maintaining documentation to ensure food safety from the beginning of the process to shipping.