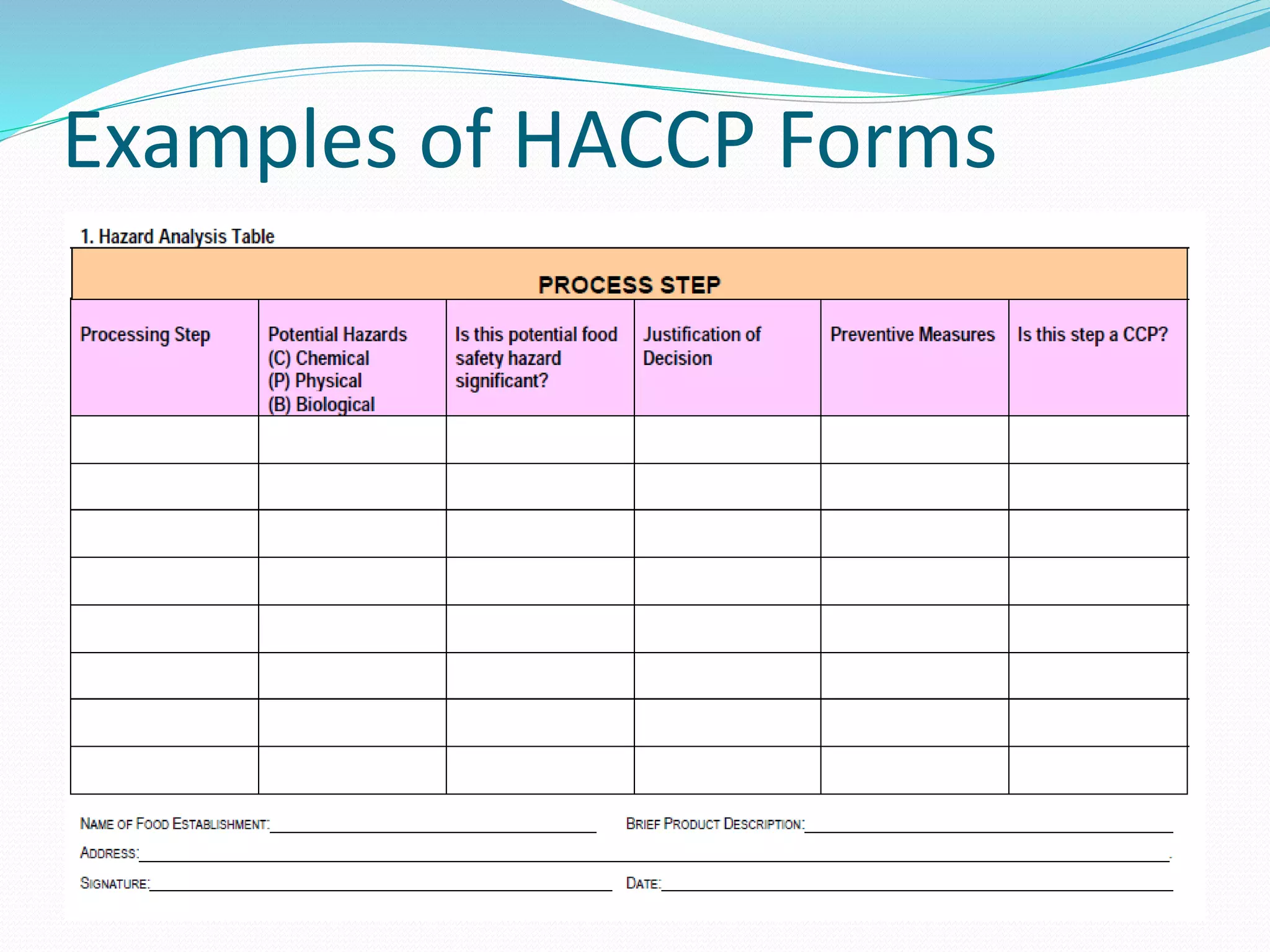

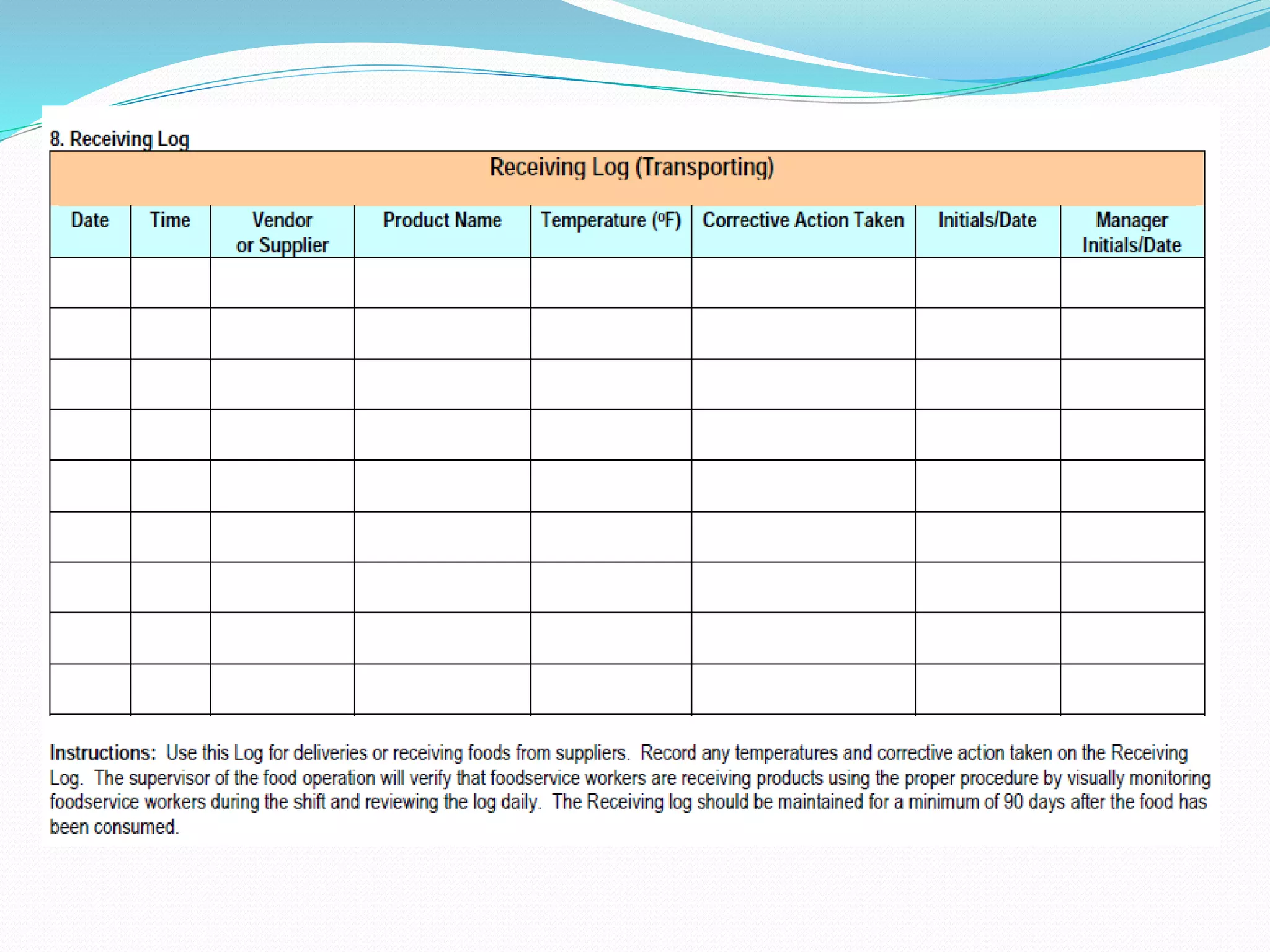

The document discusses Hazard Analysis and Critical Control Point (HACCP), a food safety system that identifies potential food hazards and establishes controls to prevent them. It outlines the seven steps of HACCP: 1) identify hazards, 2) determine critical control points, 3) establish critical limits, 4) set monitoring procedures, 5) define corrective actions, 6) establish record keeping, and 7) verify the system is working. Implementing HACCP focuses inspections on preventing problems, improves food handling practices, and ensures food safety.