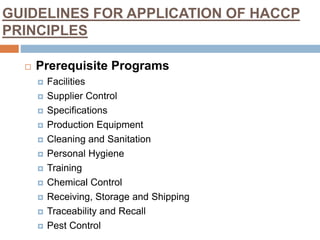

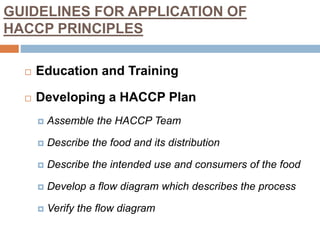

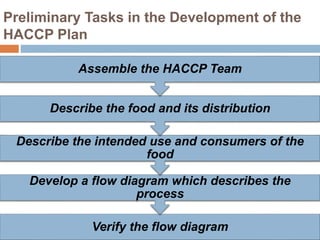

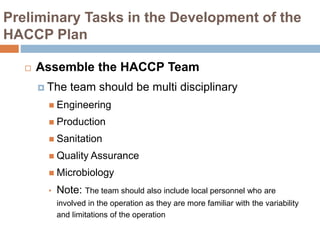

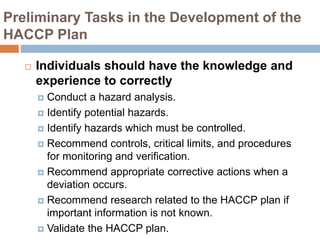

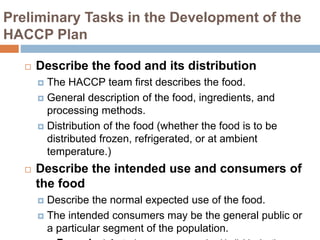

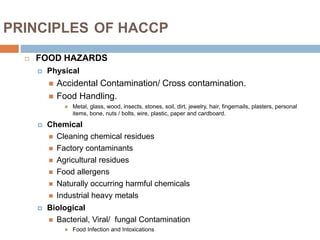

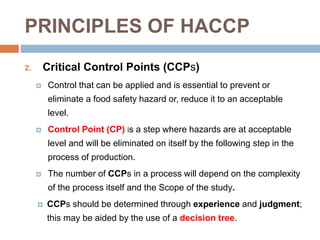

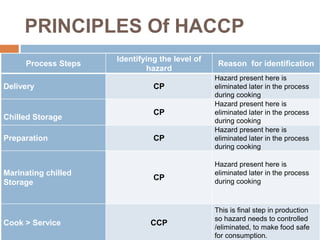

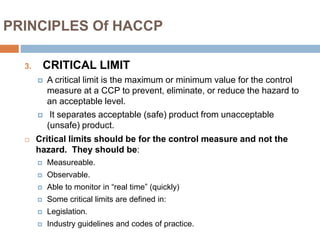

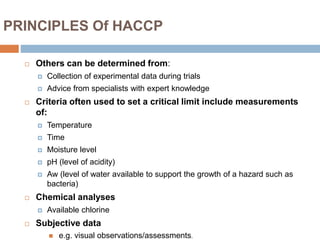

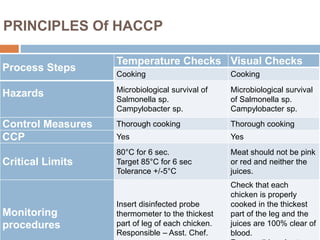

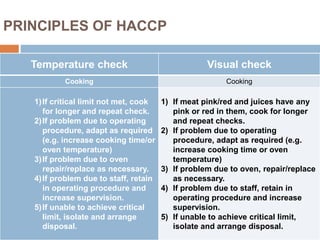

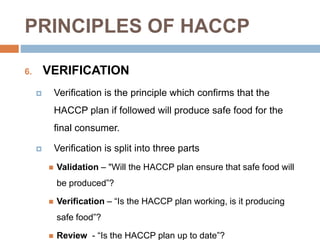

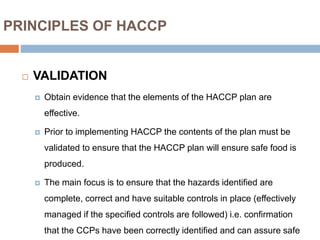

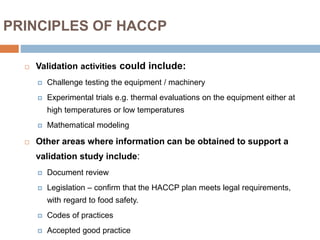

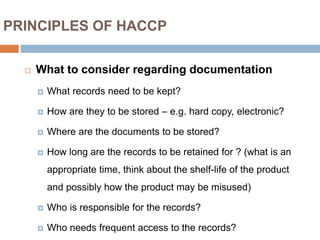

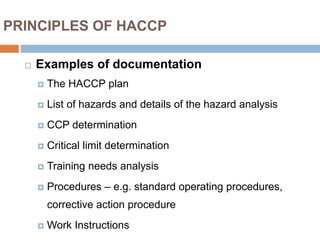

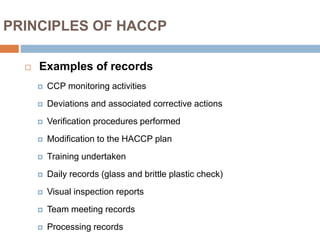

The document outlines the Hazard Analysis Critical Control Point (HACCP) system, which is essential for food safety management by identifying, evaluating, and controlling significant hazards throughout the food supply chain. It details the guidelines for implementing HACCP principles, including assembling a multidisciplinary team, conducting hazard analyses, establishing critical control points and limits, and maintaining accurate documentation for compliance. The seven principles of HACCP, including monitoring, corrective actions, and verification, are described to ensure the production of safe food.