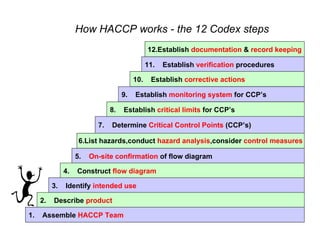

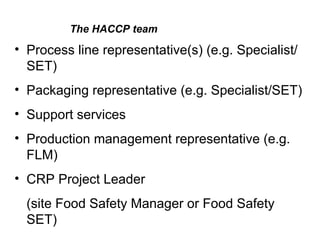

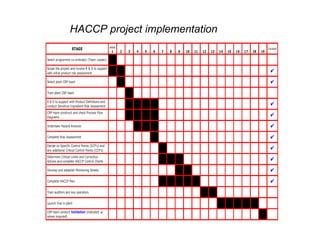

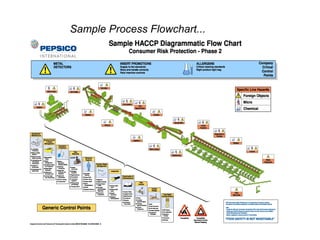

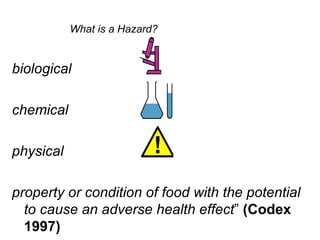

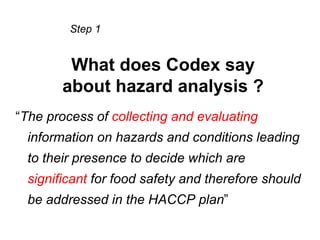

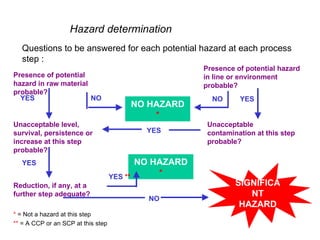

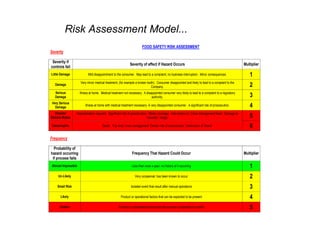

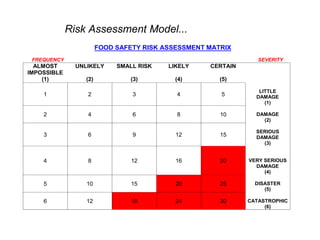

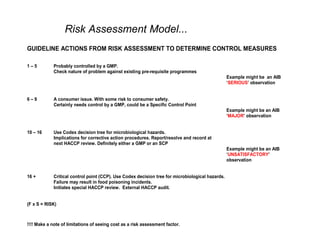

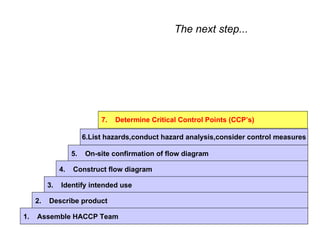

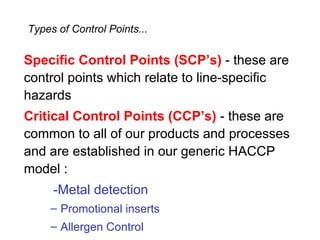

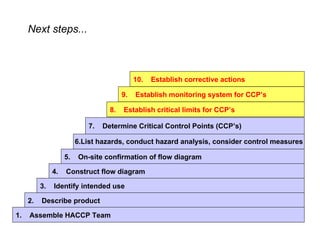

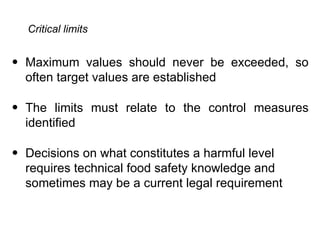

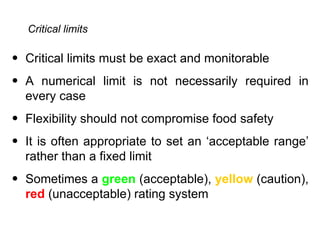

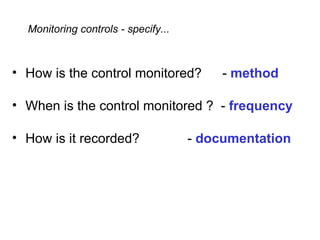

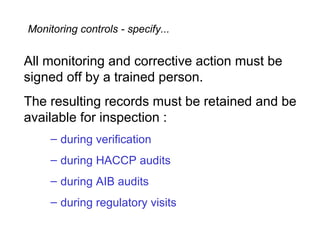

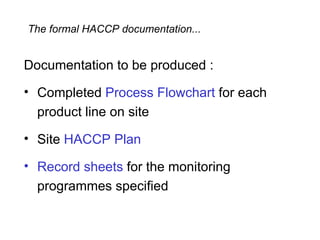

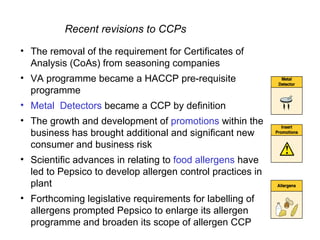

HACCP (Hazard Analysis and Critical Control Points) is a systematic preventative approach that identifies and controls hazards in the food production process. It involves assembling a team to analyze hazards, construct a flow diagram of the process, determine critical control points and critical limits. The goal is to implement control measures that eliminate or reduce significant hazards to protect consumer safety. Key aspects include hazard analysis, identifying critical control points, establishing monitoring and verification procedures, and maintaining documentation.