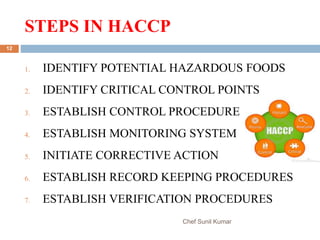

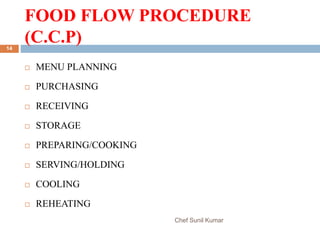

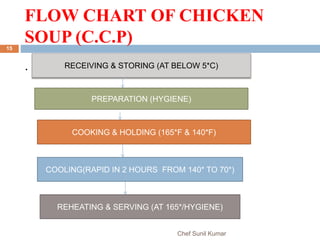

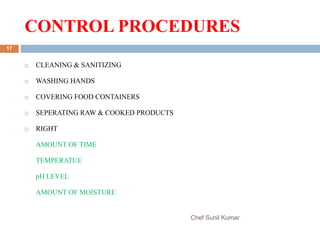

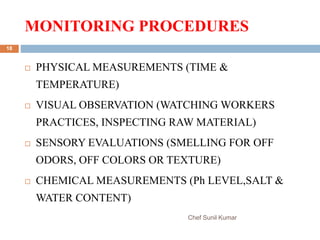

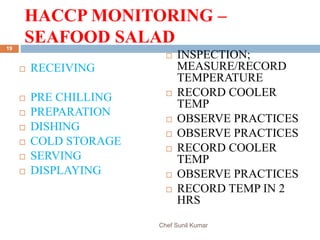

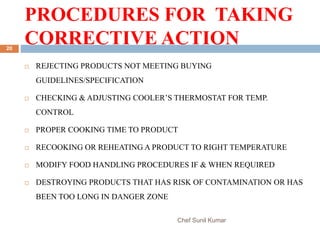

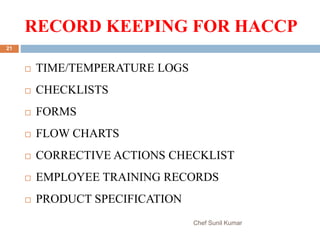

The document outlines the key concepts and steps of Hazard Analysis and Critical Control Points (HACCP), a systematic preventative approach to food safety. It discusses hazards like biological, chemical and physical contaminants that can cause foodborne illness. The 7 steps of HACCP are described, including identifying hazards and critical control points in food production processes. Monitoring procedures, corrective actions, and record keeping are important aspects of ensuring food safety through the HACCP system. The overall goal of HACCP is to anticipate and prevent risks of food contamination before they occur.