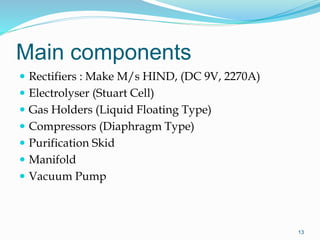

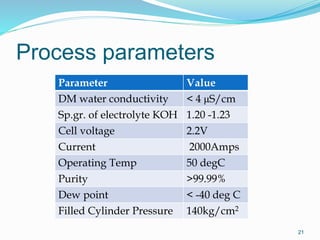

This document provides information about hydrogen generation at Simhadri power plant. It discusses the need for hydrogen as a cooling medium, and then outlines the various technologies used to produce hydrogen on-site through alkaline electrolysis. The key components of the electrolysis process are described, including rectifiers, electrolyzer cells, gas holders, compressors, and purification equipment. Safety aspects and statutory requirements are also covered at a high level.