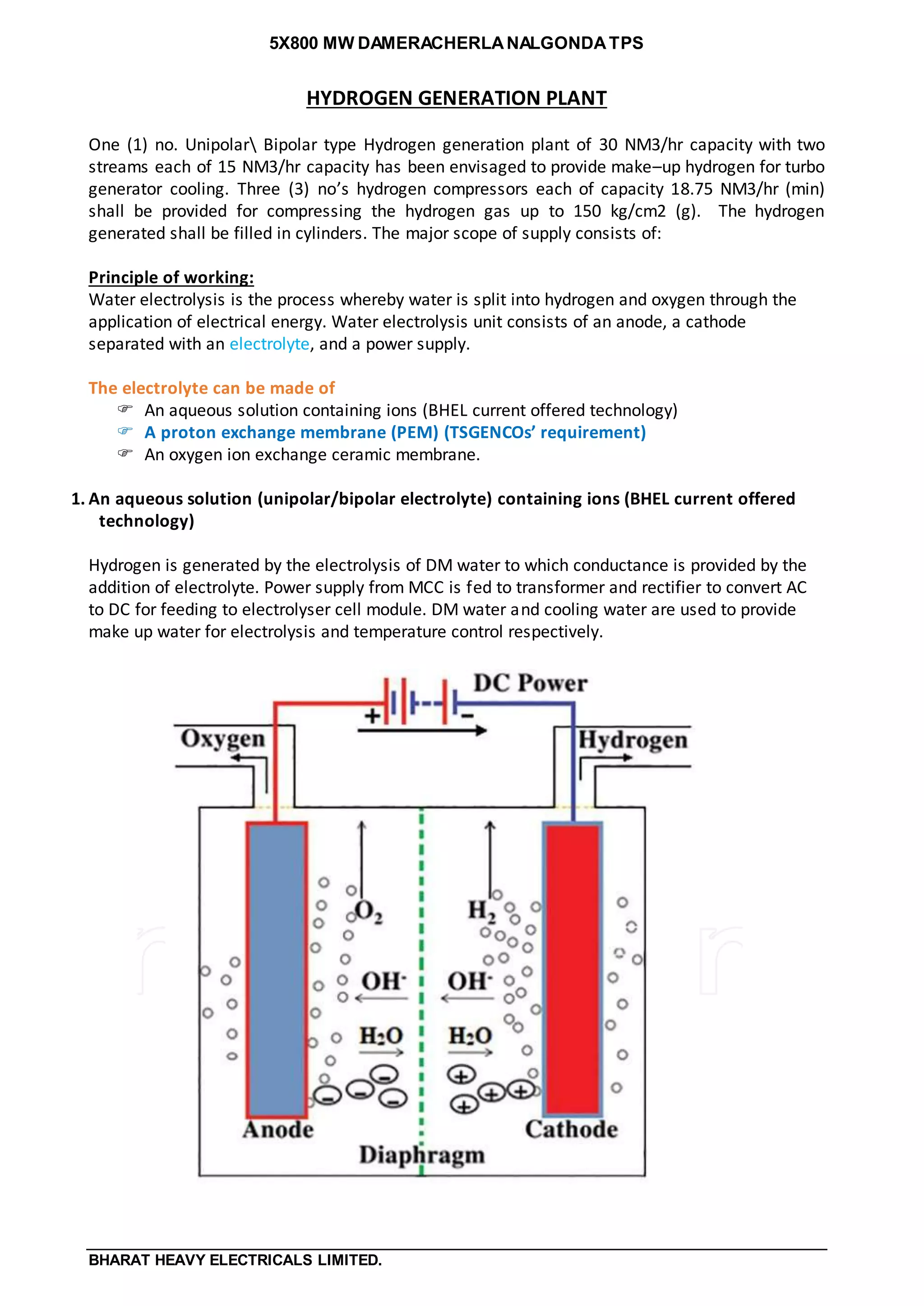

The document summarizes a hydrogen generation plant that will provide makeup hydrogen for turbo generator cooling. The plant will have a capacity of 30 NM3/hr hydrogen production across two 15 NM3/hr streams. Three hydrogen compressors will compress the hydrogen up to 150 kg/cm2. The plant uses electrolysis to split water into hydrogen and oxygen. It will either use an aqueous electrolyte solution or a proton exchange membrane, and will include components to purify, compress, and store the hydrogen in cylinders. Safety instruments like hydrogen leak detectors will also be included. The plant control system will be PLC-based.