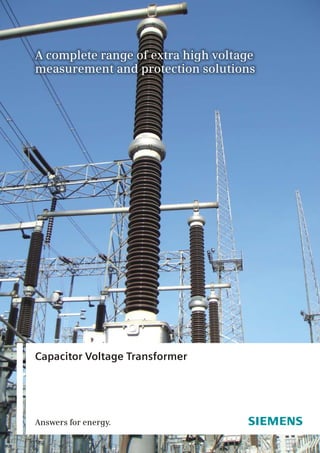

Siemens produces capacitor voltage transformers (CVTs) that convert high transmission voltages to standardized low voltages for metering, protection, and control purposes. The CVTs consist of series connected capacitor elements housed in porcelain shells that step down the voltage, with an electromagnetic circuit in an aluminum base box that provides the final output voltages. CVTs accurately transform voltages while also coupling high frequency power line carrier signals and suppressing ferroresonance to provide reliable performance over long periods of time.