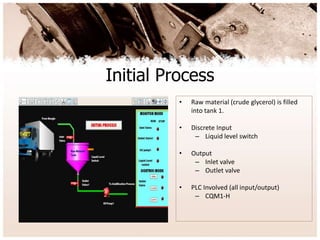

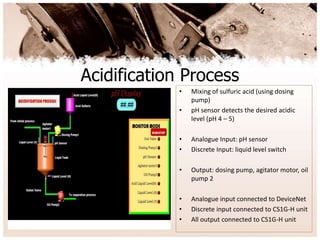

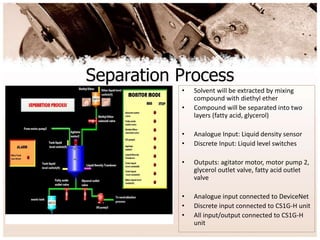

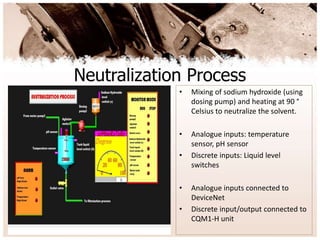

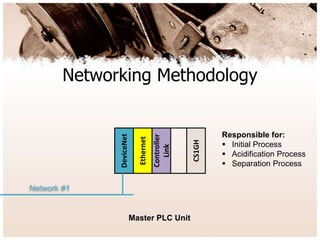

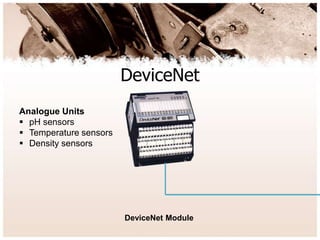

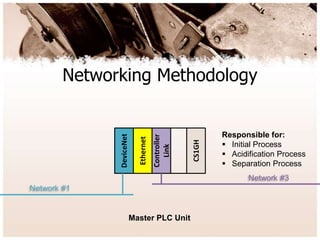

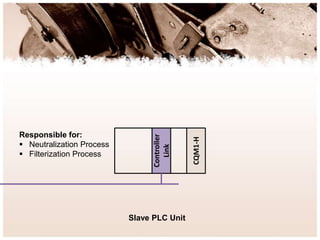

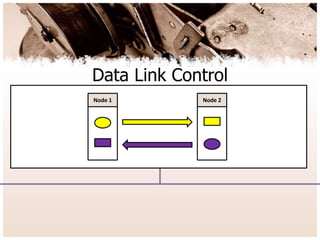

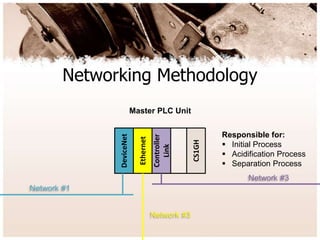

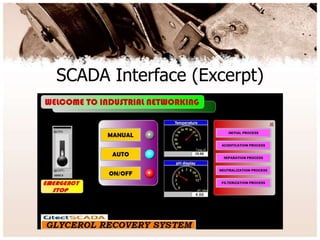

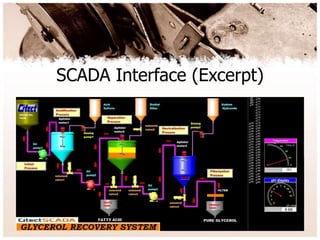

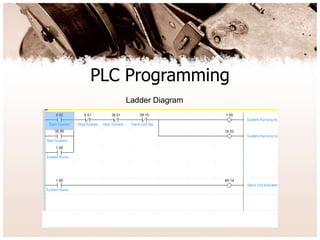

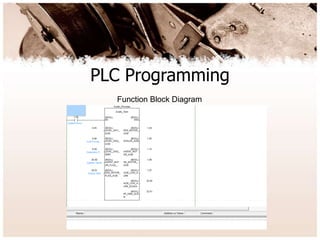

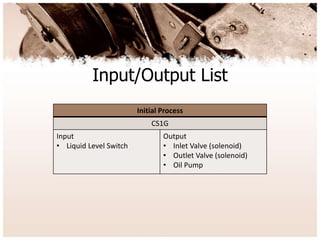

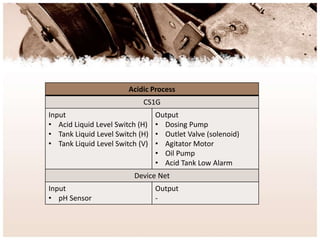

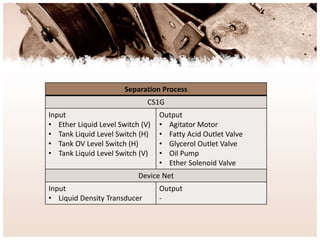

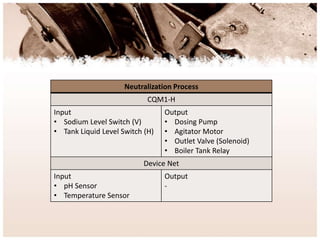

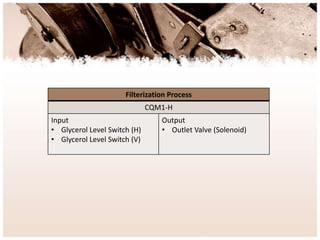

The document describes a glycerol recovery system that uses industrial networking and SCADA. The system recovers pure glycerol from crude glycerol residues through an initial process of acidification, separation, neutralization and filtering. The processes are monitored and controlled using a SCADA interface connected to PLCs via DeviceNet and Ethernet networks.