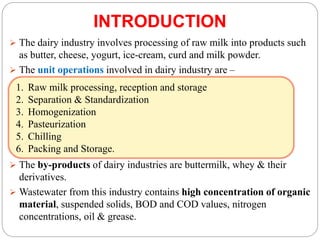

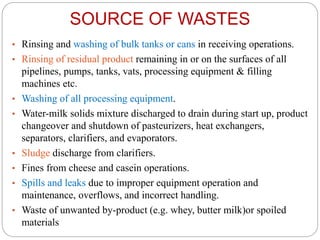

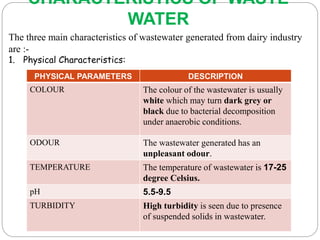

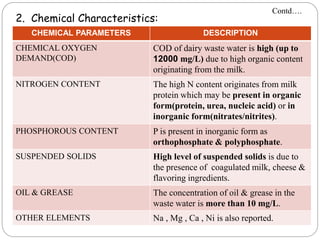

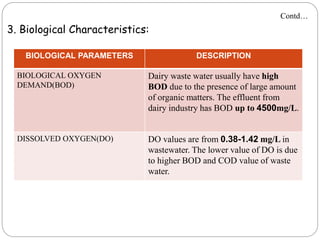

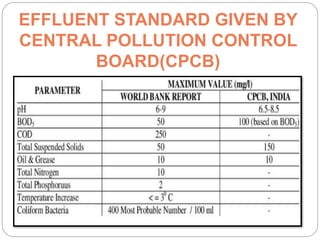

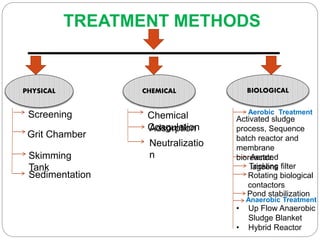

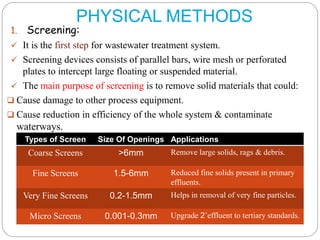

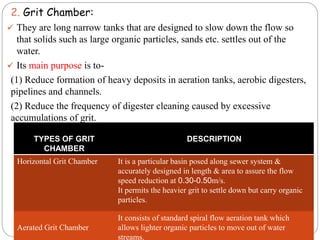

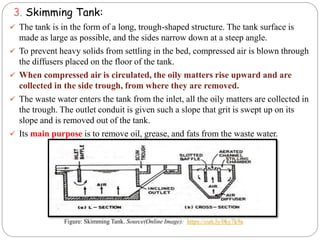

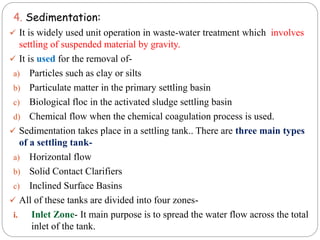

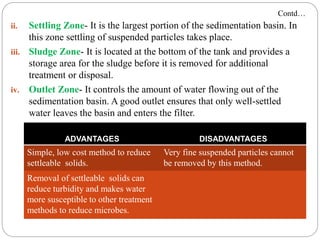

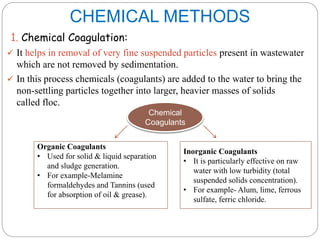

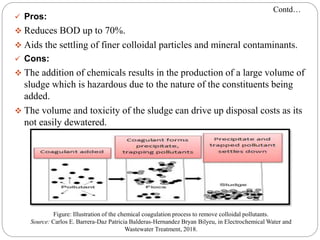

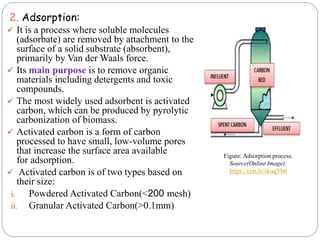

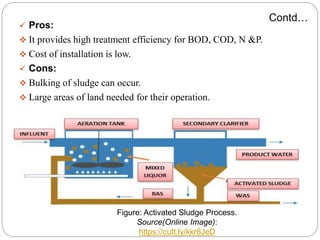

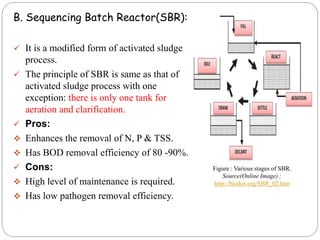

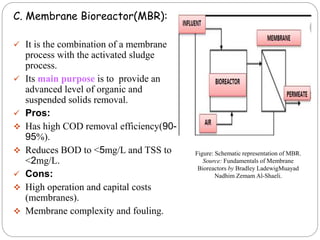

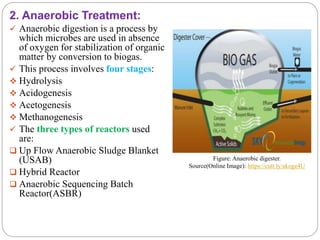

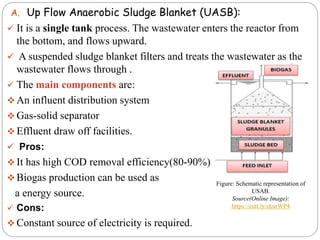

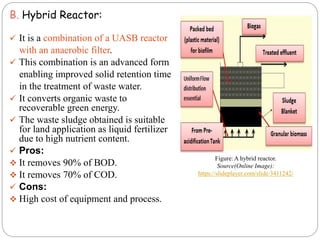

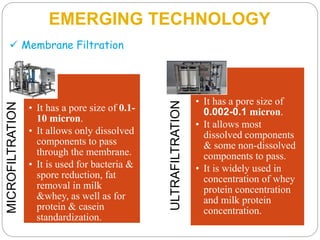

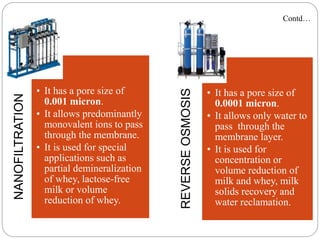

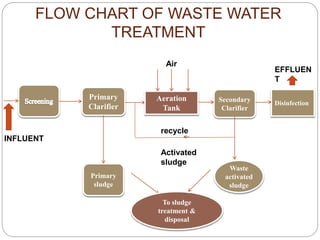

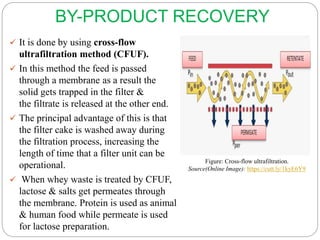

The document summarizes the treatment scheme for waste water generated from dairy industries. It describes the various sources and characteristics of the waste water including high levels of organic material, BOD and COD. It then outlines both conventional and emerging treatment methods for the waste water, including physical processes like screening and sedimentation, chemical processes like coagulation and adsorption, and biological processes like aerobic treatment and anaerobic digestion. The treatment methods aim to reduce pollutants and produce treated water and by-products that can be recovered and utilized.