Embed presentation

Downloaded 19 times

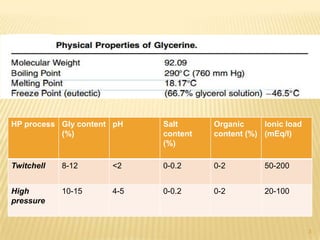

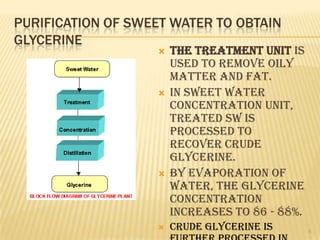

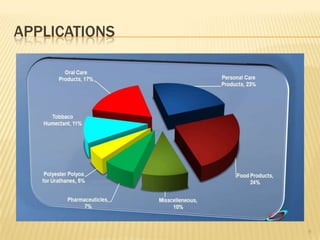

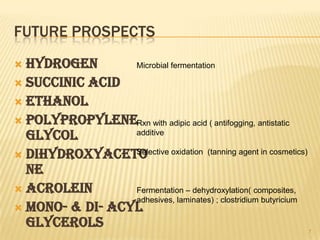

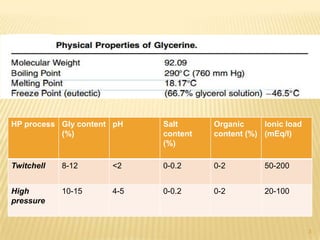

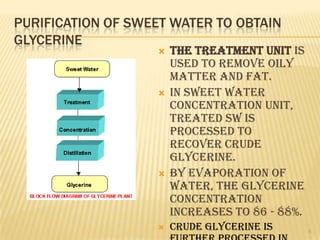

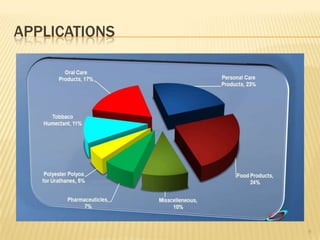

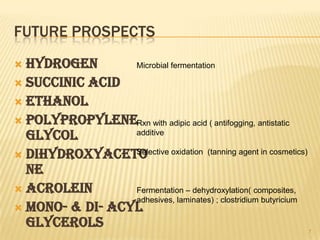

Sweet water is a byproduct mixture of water and glycerin obtained from fat splitting processes like enzymatic splitting and the Twitchell process. Sweet water contains 8-15% glycerin, has a pH below 5, and contains small amounts of salt, organic material, and ions. It can be purified by removing oily matter, concentrating the glycerin to 86-88% through evaporation, yielding crude glycerin. Crude glycerin has applications and potential can be used as a source for hydrogen, succinic acid, ethanol, and other compounds through fermentation or chemical reactions.