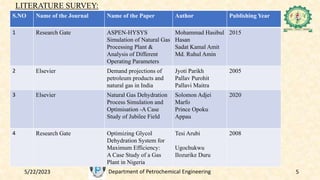

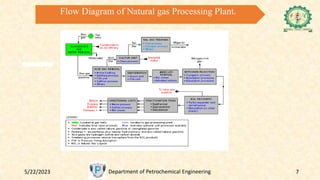

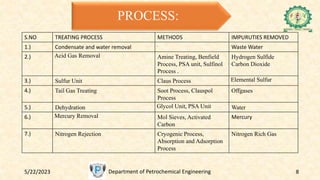

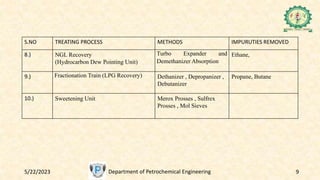

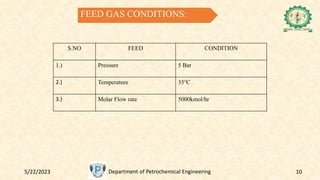

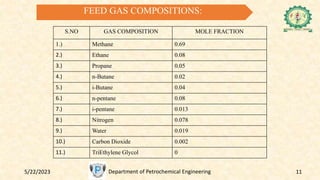

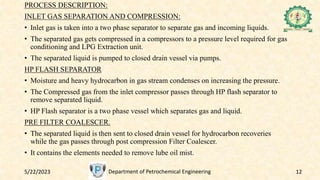

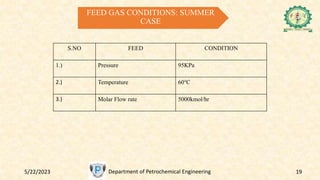

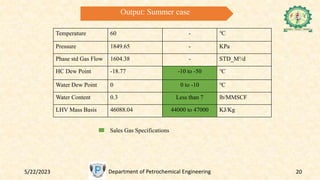

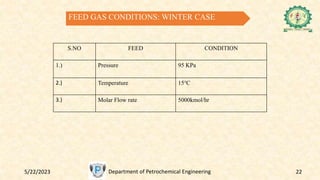

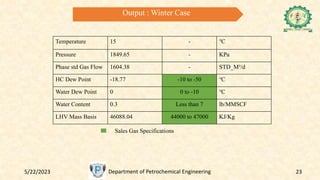

The document outlines a student project to simulate a 20MMSCFD natural gas treating plant using Aspen HYSYS. A team of 4 students is supervised by an internal and external guide. The objectives are to design and simulate the plant in summer and winter cases, and optimize the plant. The document describes the feed gas conditions and compositions, various treating processes to remove impurities like H2S and CO2, simulation of dehydration, cryogenic recovery of NGLs, and results showing no change in LPG production between cases.