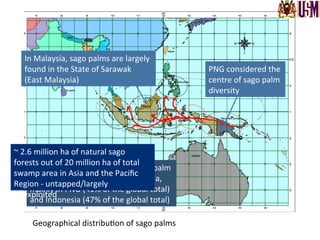

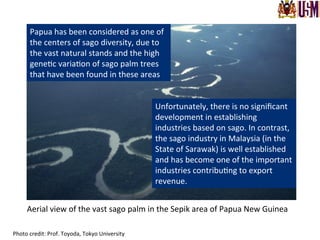

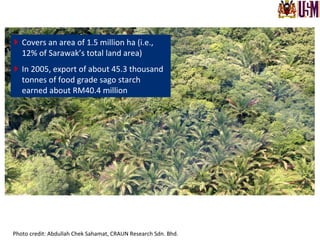

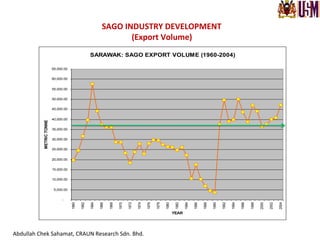

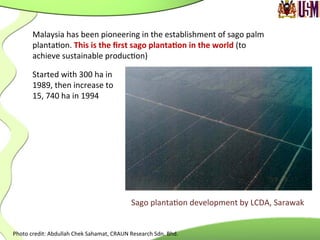

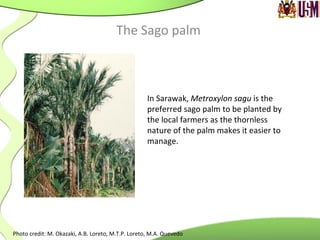

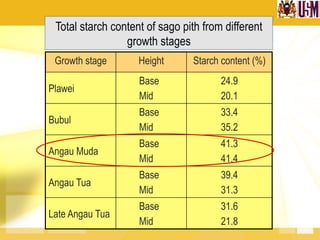

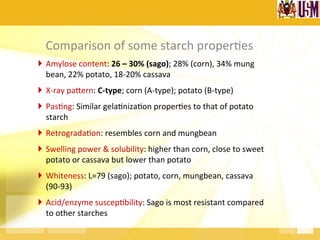

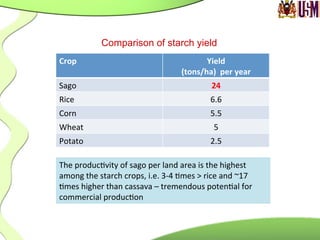

The document discusses the sago palm (Metroxylon sagu), highlighting its high starch yield potential compared to other crops and its challenges in production and processing. While sago is a staple food in some regions of Asia and the Pacific, it remains largely unexploited with low-quality starch due to outdated practices. The document emphasizes the sago industry's development in Malaysia, particularly in Sarawak, and its potential for economic growth in the global starch market.

![Sago

palm

in

the

wild

Photo

credit:

M.

Okazaki,

A.B.

Loreto,

M.T.P.

Loreto,

M.A.

Quevedo

(le]);

Dulce

Flores

(right)

} Sago

palm

is

found

growing

wild

in

the

marshlands

where

other

crops

cannot

thrive.

} Sago

palm

thrives

in

wetland,

swampy

area,

and

other

areas

where

water

is

abundant.](https://image.slidesharecdn.com/gettingtoknowsagopalmandstarch-vista-130813015021-phpapp01/85/Getting-to-know-sago-palm-and-starch-10-320.jpg)

![Sago

palm

–

the

robust

crop

Photo

credit:

M.

Okazaki,

A.B.

Loreto,

M.T.P.

Loreto,

M.A.

Quevedo

(le]);

Dulce

Flores

(right)

} Sago

palm

is

tolerant

of

low

pH,

high

levels

of

Al,

Fe,

and

Mn

in

the

soil,

soil

salinity,

as

well

as

heavy

impervious

clays

} Hence,

it

has

a

strong

advantage

for

cul.va.on

in

underu.lized

wet

and

peat

swamp

rain

forests

for

increasing

agricultural

produc.on](https://image.slidesharecdn.com/gettingtoknowsagopalmandstarch-vista-130813015021-phpapp01/85/Getting-to-know-sago-palm-and-starch-11-320.jpg)