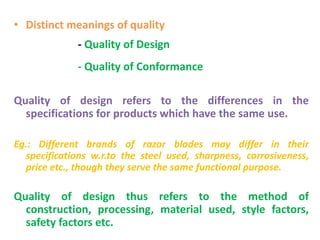

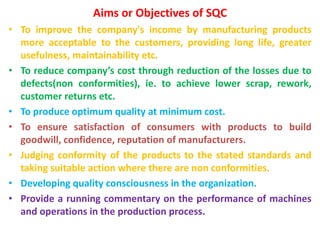

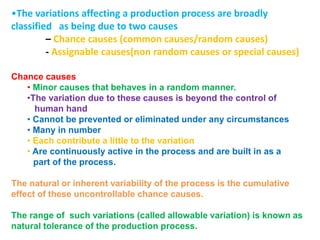

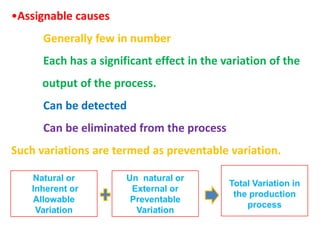

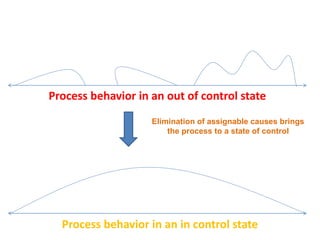

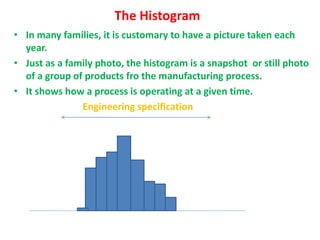

This document provides an overview of statistical quality control. It defines quality as satisfying customer needs and discusses how quality is planned, achieved, controlled, and continuously improved. It describes distinguishing quality of design from quality of conformance. Quality control techniques are used to manage all production steps to achieve desired quality. Control charts in particular help monitor processes for assignable causes of variation and ensure processes are in a state of statistical control. The document outlines principles of statistical process control like variability, measurement, normal distribution, and how assignable causes distort patterns. Histograms provide snapshots of process performance while control charts continuously monitor processes.