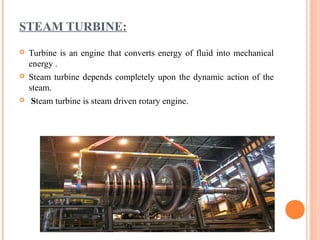

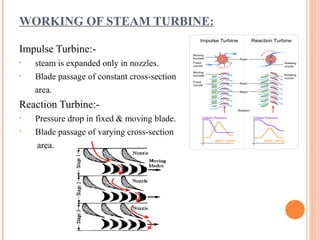

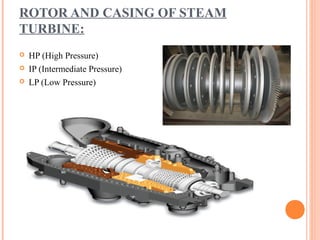

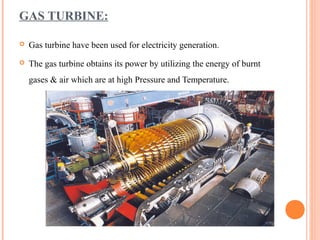

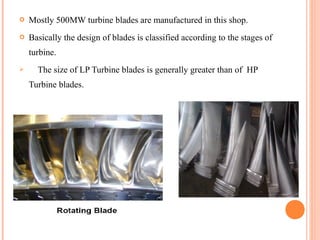

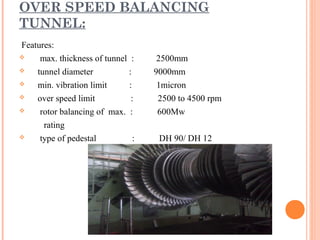

BHEL is India's largest power equipment manufacturer, established over 40 years ago. It has 14 manufacturing divisions and produces equipment for power plants, defense, and other industries. The document describes BHEL's turbine manufacturing shop, which produces steam and gas turbines through processes like machining, grinding, and balancing blades in an overspeed tunnel. Turbines have rotors, casings, and blades of different sizes for high, intermediate, and low pressure stages. BHEL manufactures turbines up to 600MW and aims to produce 500MW nuclear turbine sets in the future.