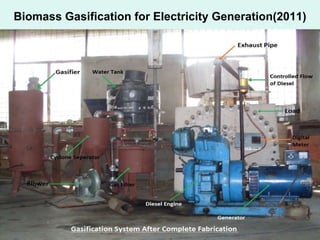

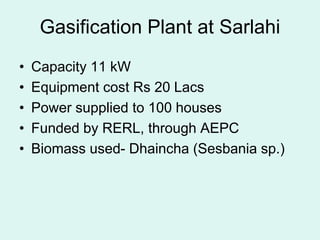

This document describes a biomass gasification system developed by Prof. Dr. Krishna Raj Shrestha and his team at the Research Centre for Applied Science and Technology (RECAST) in Nepal. The system was tested at loads of 3 kW and 6 kW, achieving overall efficiencies of 9.45% and 15.36% respectively when using producer gas and diesel in dual mode. In single gasification mode, the system achieved efficiencies of 79.13% and 84.03% at the two loads. The document provides details on the gasification process, equipment used, types of biomass available in Nepal as feedstock, and test results for temperature, pressure and emissions.

![Agro residues

Crop type Area

[Ha]

Crop Prod

[MT]

Residue

type

RPR* Total Residue

Prod [MT]

Paddy 1,531,493 5,072,248 Total

residue

1.68 8,521,376

Husk 0.267 1,354,290

Maize 871387 2179414 Total

residue

5,389,691

stalk 2 4,358,828

cob 0.273 594,980

husk 0.2 435,883

Millet 278030 315067 stalk 1.08 340,272

Wheat 765317 1846142 straw 1.75 3,230,748

Buckwheat 10339 10021 Straw 1 10,021

Barley 27966 34829.8 straw 1.75 60,952](https://image.slidesharecdn.com/negagasifierpresentation9-170209053500/85/Gasifier-presentation-Prof-K-R-Shrestha-10-320.jpg)

![Agro residues (cont)

Crop type Area

[Ha]

Crop Prod

[MT]

Residue type RPR Total Residue

Prod [MT]

Oil Seed 214835 179145 Stalk 4.01 71,837

Sugarcane 64472 2930047 Bagasse 0.29 849,714

tops/leaves 0.3 879,014

Total 1,728,728

Jute 10540 14424 Stick 2 28,848

Soybean 29281.8 28269.8 Total 98,944.3

Straw 2.5 70,674.5

Pods 1 28,269.8

Black Gram 27496.2 22482.4 Straw/stick 1.66 37,320

Cotton 135 133 Sticks 2.75 365.75

Coconut Husk 0.419 NA

Shell 0.12 NA

Coffee 1780 425000 Husk 2.1 892,500

Ground nut 2736 3869 Husk 0.477 1,845

Straw 2.30 8,899](https://image.slidesharecdn.com/negagasifierpresentation9-170209053500/85/Gasifier-presentation-Prof-K-R-Shrestha-11-320.jpg)