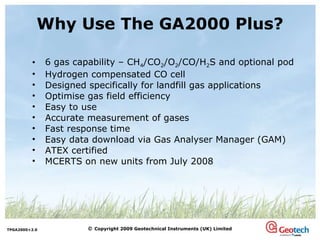

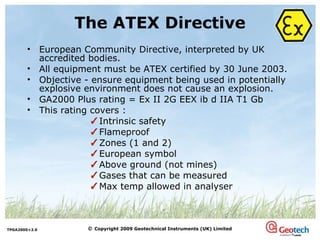

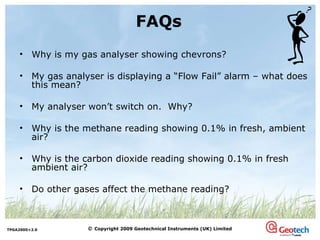

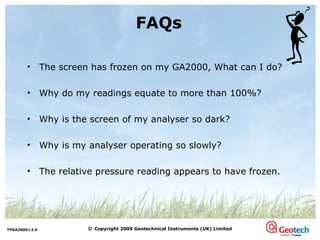

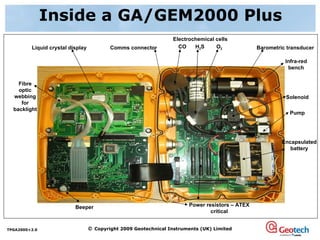

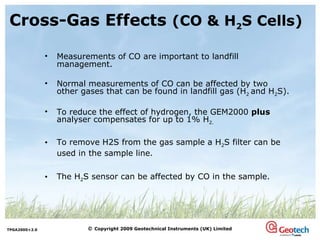

The document provides an overview of a training session on Geotech's GA2000 Plus landfill gas analyser. It discusses the history and development of Geotech's gas analyser products, how the GA2000 Plus works, its certifications, support services available, and addresses common questions. Hands-on demonstrations are included to showcase operation and calibration.

![Service Support Experienced and skilled engineers. Fast 7 day turnaround. Analyser collection service available. Service contracts & schemes (service plus). Comprehensive hire fleet. E-mail reminders and acknowledgements. DSEAR compliant auto-cal facilities. Andy, Sue and Dean…… Tel: +44 (0)1926 338111 Email: [email_address]](https://image.slidesharecdn.com/ga2000salestraningtaster-12988890350622-phpapp02/85/GA2000-Traning-Taster-29-320.jpg)

![Technical Support Provide detailed support & troubleshooting on all Geotech products via phone or e-mail. Team with over 40 years of experience. Always looking for feedback. James, James, Craig, Tim and Dean…… Tel: +44 (0)1926 338111 email: [email_address]](https://image.slidesharecdn.com/ga2000salestraningtaster-12988890350622-phpapp02/85/GA2000-Traning-Taster-30-320.jpg)

![Customer Support Dedicated team to make your Geotech experience as smooth and trouble-free as possible. Communicate effectively with customers on all order enquiries. Provide any necessary ‘after-sales’ support. Sharan and Maureen…… Tel: +44 (0)1926 338111 email: [email_address]](https://image.slidesharecdn.com/ga2000salestraningtaster-12988890350622-phpapp02/85/GA2000-Traning-Taster-31-320.jpg)