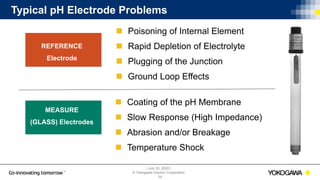

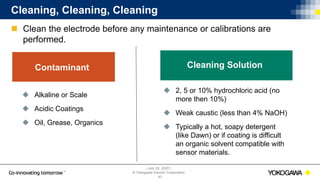

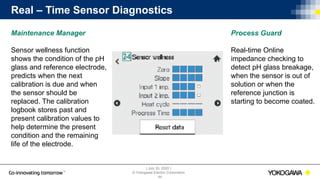

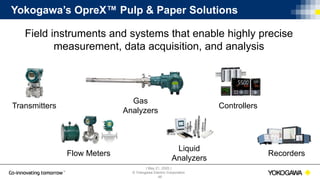

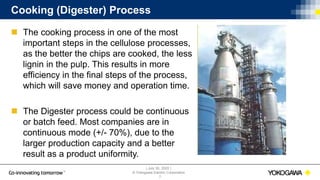

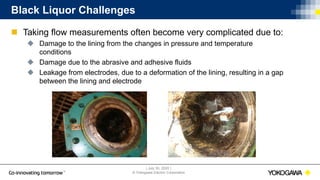

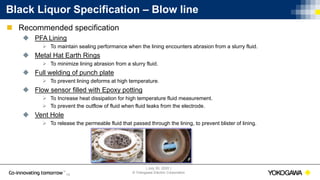

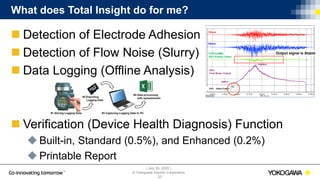

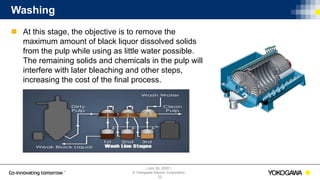

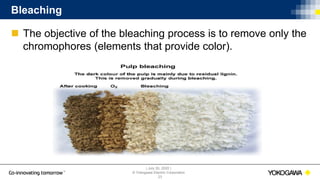

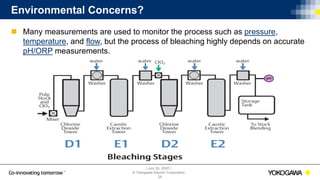

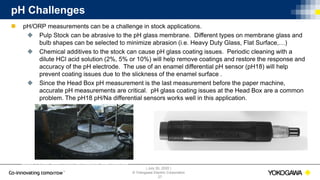

The document discusses applications of pH and other process measurements in pulp and paper mills. It notes that accurate pH measurements are critical for bleaching processes due to environmental regulations. It also explains that pH measurements can be challenging due to abrasive pulp stock and chemical additives, requiring frequent sensor cleaning and maintenance to ensure accuracy. New sensor designs aim to reduce maintenance needs to make pH measurement more manageable for mill operators.

![| July 30, 2020 |

© Yokogawa Electric Corporation

30

Copyright © Yokogawa Corporation of America

pH – Acid or Base?

NEUTRAL

ACID

BASE

1.0

0.1

0.01

0.001

0.0001

0.00001

0.000001

0.0000001

0.00000001

0.000000001

0.0000000001

0.00000000001

0.000000000001

0.0000000000001

0.00000000000001

[H+ ]

.00000000000001

.0000000000001

.000000000001

.00000000001

.0000000001

.000000001

.00000001

.0000001

.000001

.00001

.0001

.001

.01

0.1

1.0

[OH- ]

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

pH

pH = -log [H+](Hydrogen Ion Concentration)

Moles/Liter](https://image.slidesharecdn.com/pulpmillapplications-200930162035/85/Pulp-mill-applications-31-320.jpg)