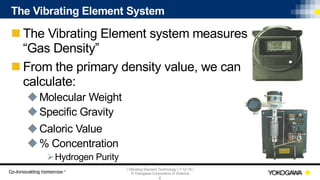

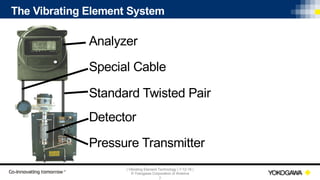

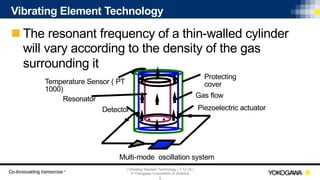

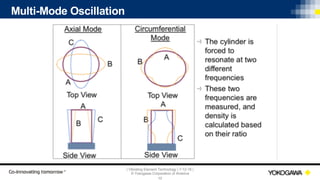

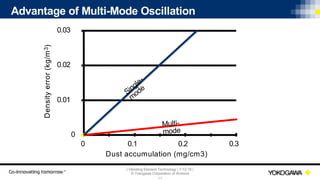

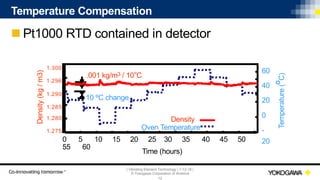

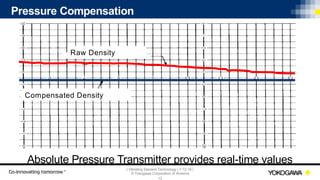

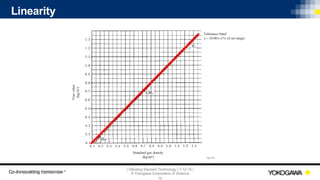

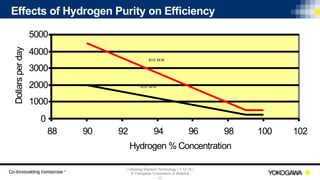

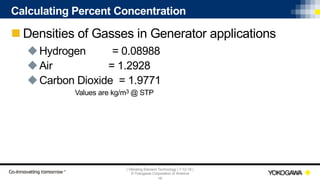

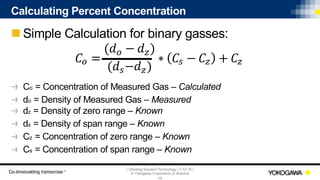

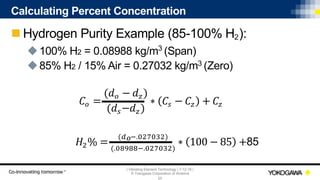

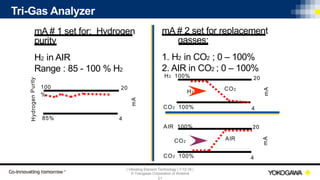

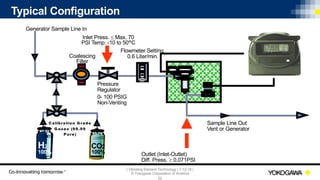

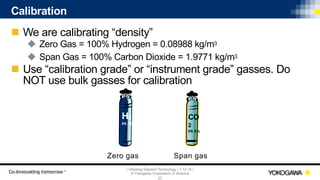

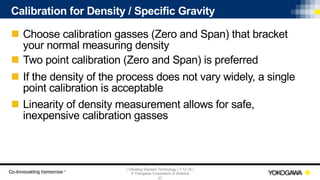

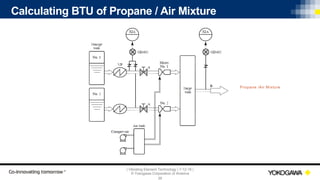

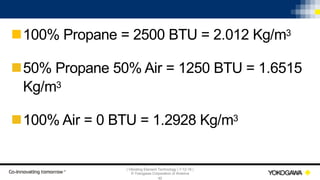

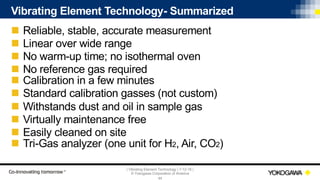

The document discusses vibrating element technology for measuring gas density, specific gravity, and hydrogen purity. It describes how vibrating element analyzers measure density and use that measurement to calculate other parameters like molecular weight, specific gravity, caloric value, and concentration. The document outlines applications in power plant hydrogen cooling, refineries, and how vibrating element technology provides reliable, accurate, and maintenance-free density measurement over a wide range.