Deterioration factors of Fruits and Vegetables and their control

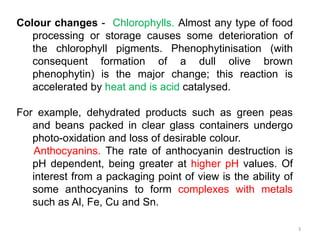

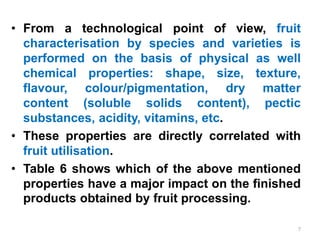

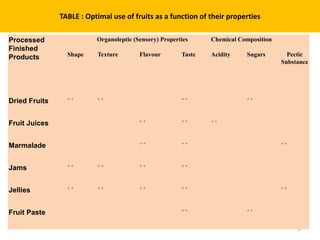

Enzymes in plant tissues can cause undesirable changes like browning or desirable changes like ripening. Enzyme activity is controlled by factors like temperature, pH, and chemicals. Chemical changes like lipid oxidation and non-enzymatic browning also lead to food deterioration. Proper harvesting, handling, storage, and packaging can help control deterioration factors and maintain quality. Quality is assessed through measurements of color, texture, soluble solids, acidity, and sugar to acid ratio.