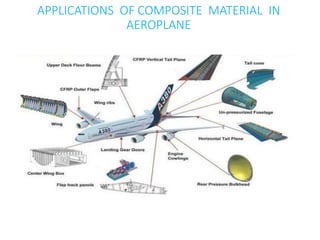

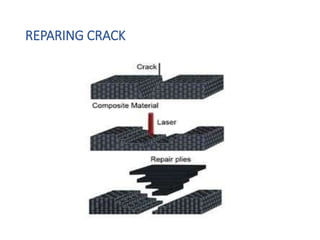

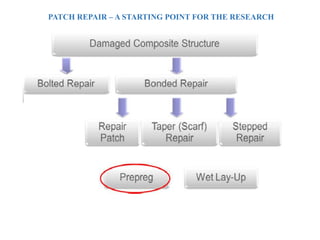

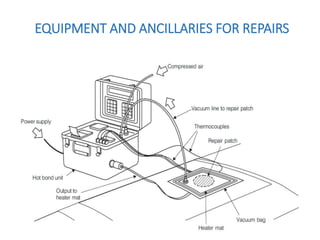

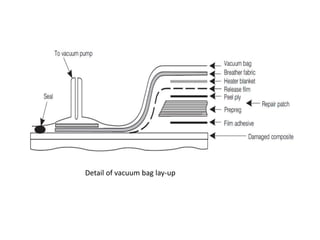

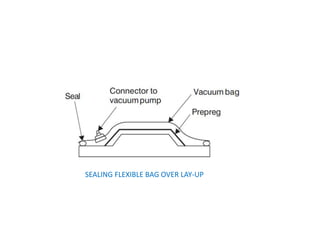

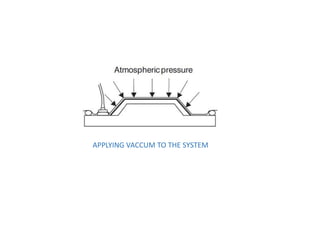

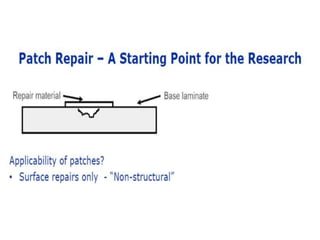

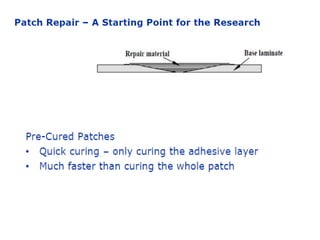

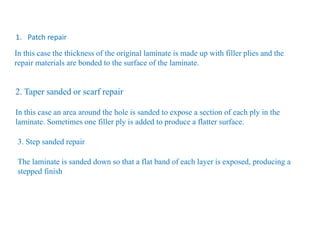

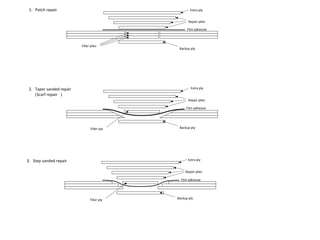

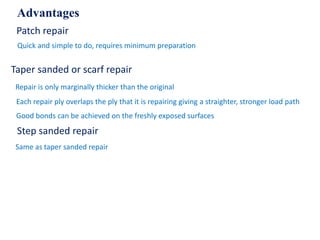

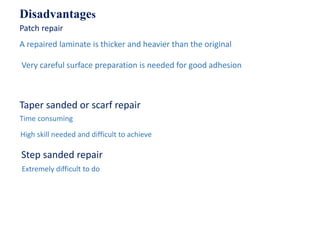

This document discusses composite material repair methodologies. It begins by defining a composite material as one made of two or more materials with different properties combined to produce a new material with unique characteristics. It then discusses some common applications of composite materials in airplanes. The main types of composite damage on airplanes are then outlined, such as impact damage, erosion, scratches, and damage through the full structure. Various repair techniques are presented, including non-patching methods like resin infusion as well as patching methods like bonded external patches and bonded scarf patches. Equipment used for repairs like vacuum bags are also depicted. Finally, the document concludes that reliable repair methods are necessary to restore structural integrity to composite materials increasingly used in aircraft.