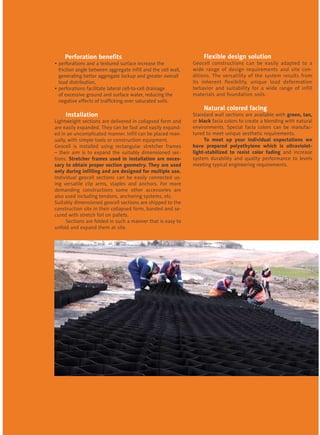

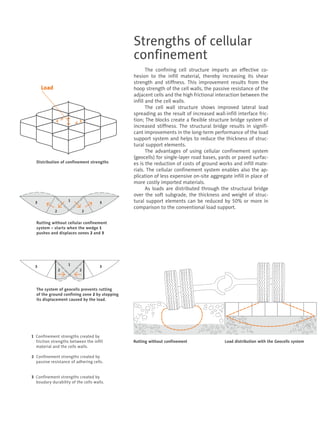

The document discusses the cellular confinement system known as geocells, which enhances the performance of materials like gravel and sand by confining them, leading to better soil stabilization and cost reduction. Developed in the late 1970s, this technology has applications in road construction, erosion control, and stormwater management, featuring various infill materials. The document highlights its environmental safety, ease of installation, and versatility in design, supported by the manufacturer's commitment to quality and innovation.