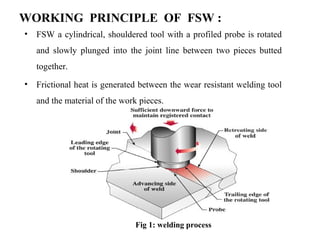

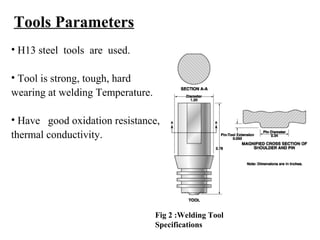

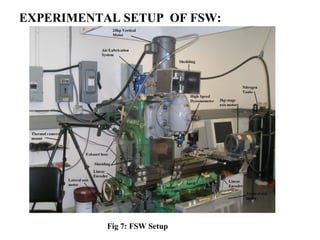

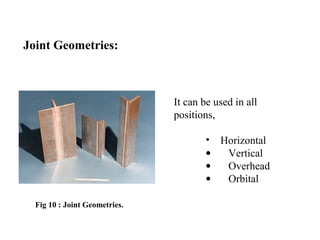

Friction stir welding is a solid state joining process that was invented in 1991. It involves a cylindrical shouldered tool that is rotated and plunged into butt joints of materials to be welded. Frictional heat generated between the tool and materials plasticizes them without melting. As the tool traverses along the weld line, the plasticized material is transferred from the front of the tool to the back, consolidating into a weld. It can weld a variety of materials like aluminum alloys, copper, magnesium, and steel. Advantages include high joint strength, low environmental impact, and ability to weld in all positions. Applications include aerospace, shipbuilding, automotive, and fabrication industries.