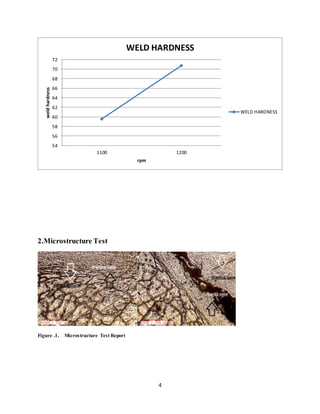

Friction stir welding was performed on aluminum alloy AA6061 reinforced with 6% Al2O3 particles. Testing found that welds produced at 1100 rpm tool rotation had the highest tensile strength, breaking stress, and percentage elongation compared to 1200 rpm. Hardness was also lowest at 1100 rpm. Microstructure analysis showed a homogeneous material flow pattern within the weld nugget. Overall joint efficiency was highest when welding at 1100 rpm tool rotation.