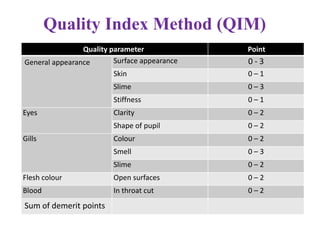

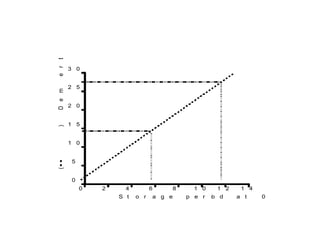

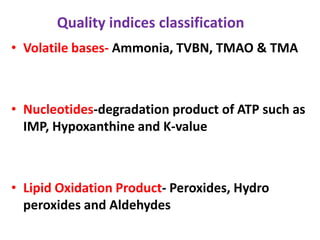

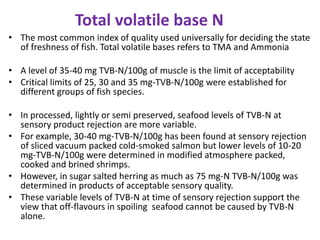

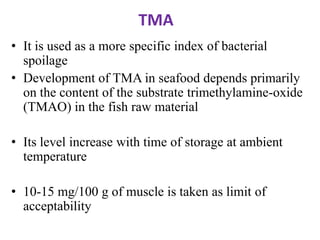

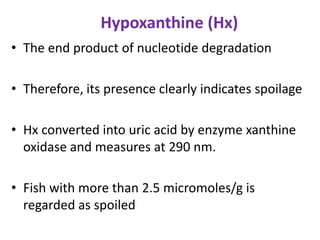

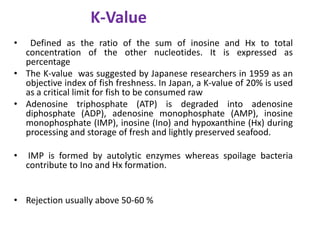

This document discusses various methods for assessing the freshness and quality of seafood, including sensory analysis using trained assessors, EU freshness grading schemes, and the Quality Index Method (QIM). It also describes several chemical quality indices used to quantify spoilage compounds, such as total volatile bases (TVB-N), TMA, indole, hypoxanthine, and K-value. Instrumental analysis methods like the Fishtester and RT-Freshtester provide rapid measurements of fish quality but require calibration and have high costs. Overall, the document outlines both sensory and chemical analysis techniques for evaluating seafood freshness and determining remaining shelf life.