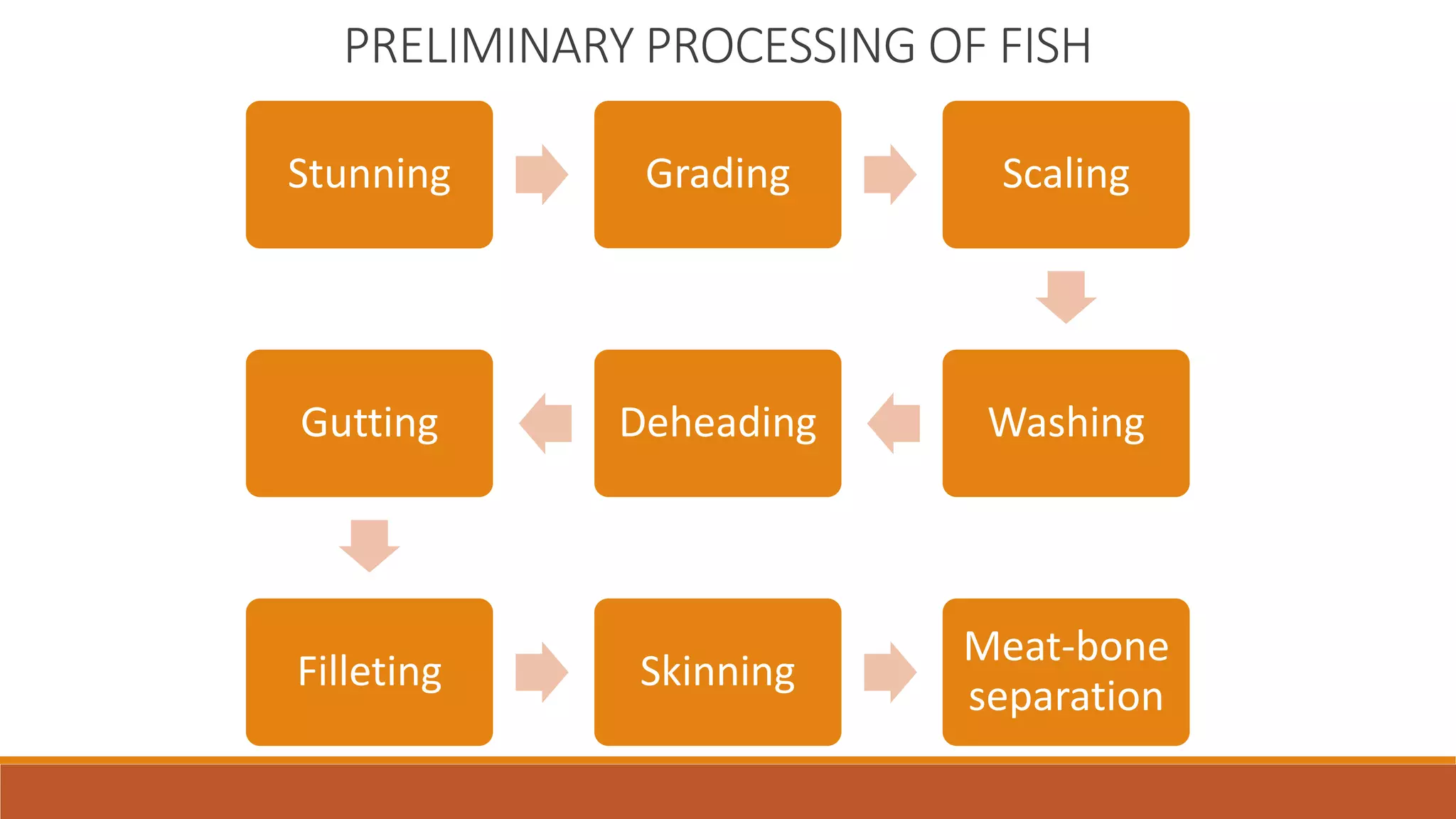

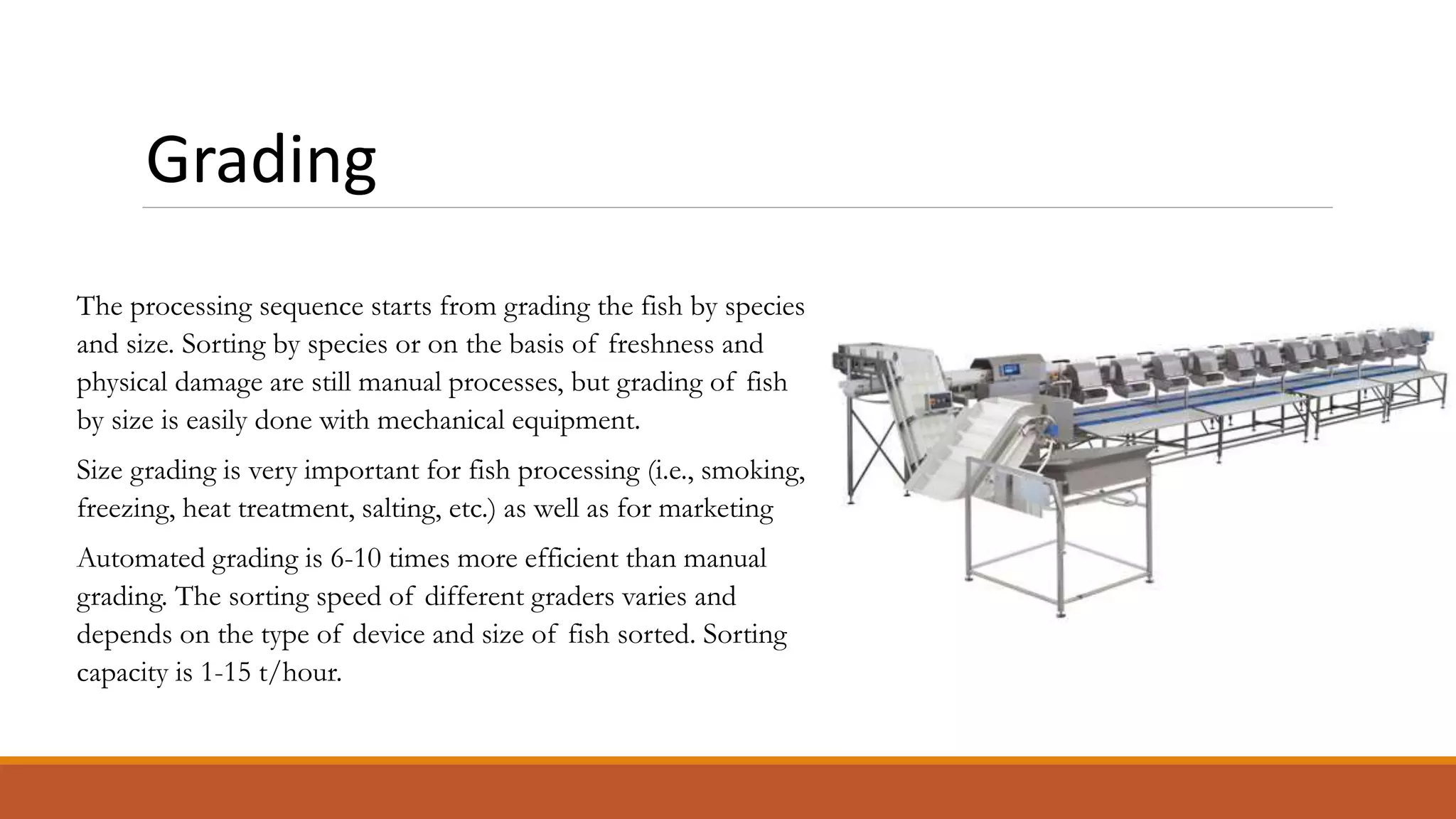

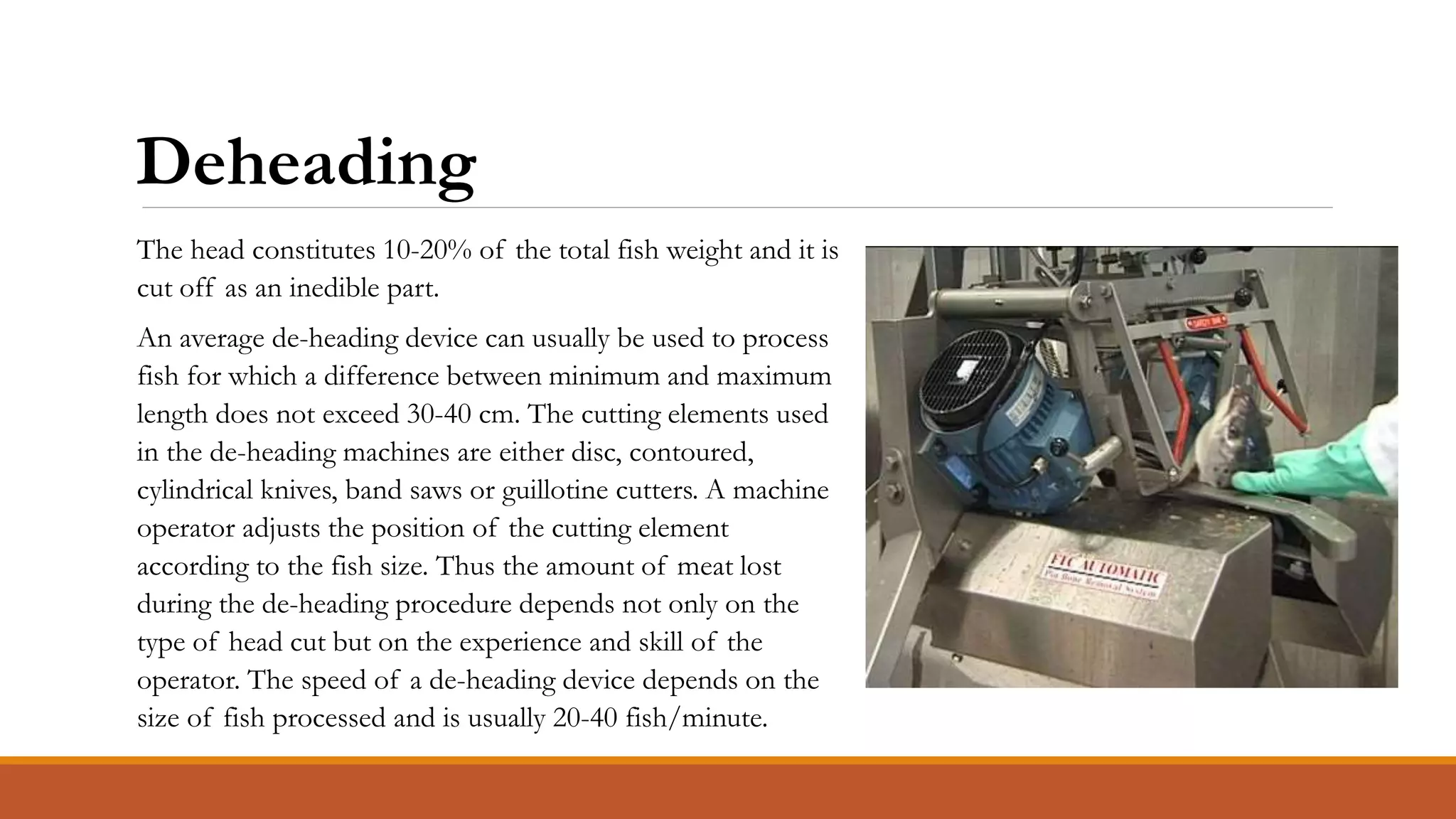

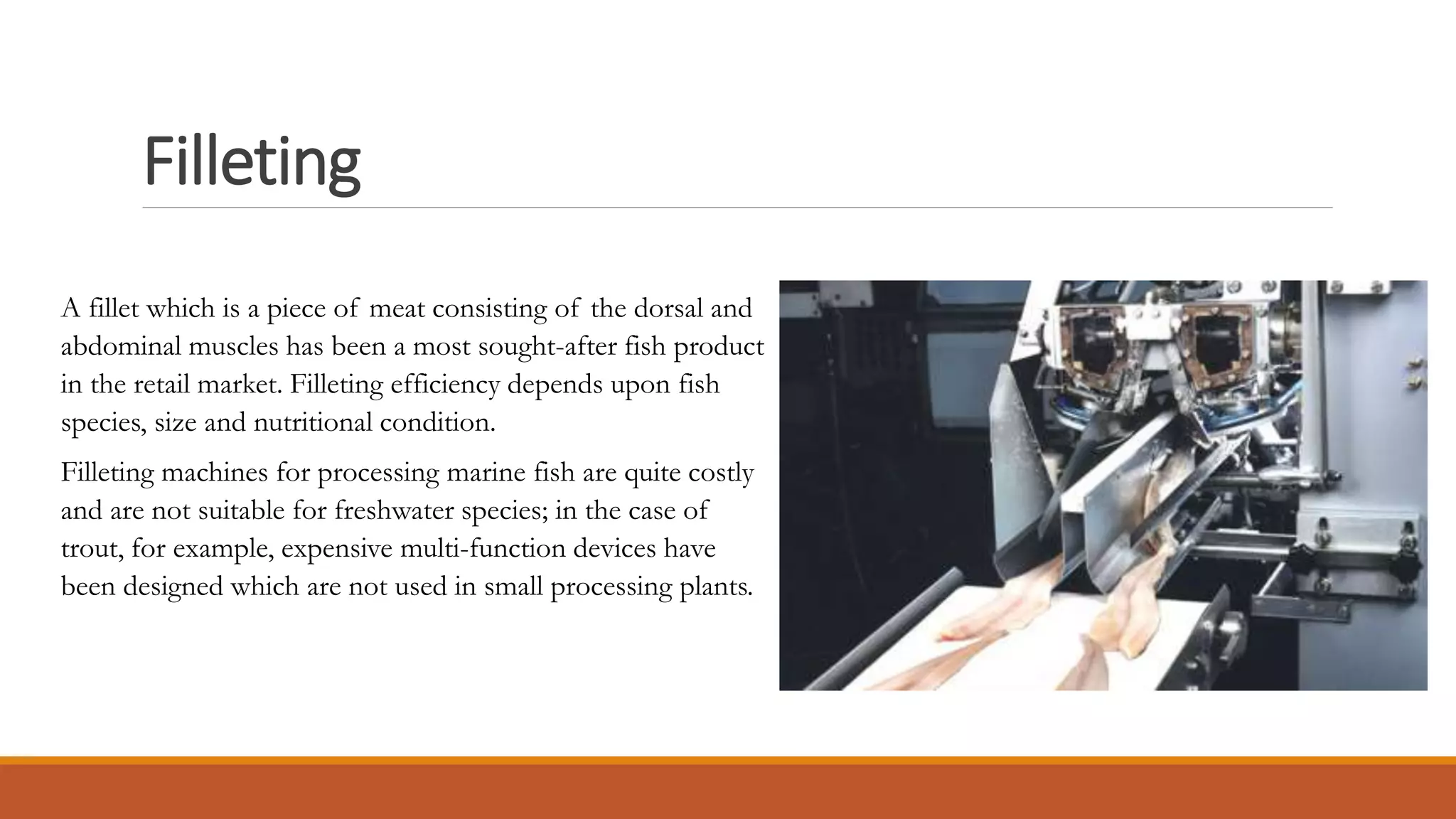

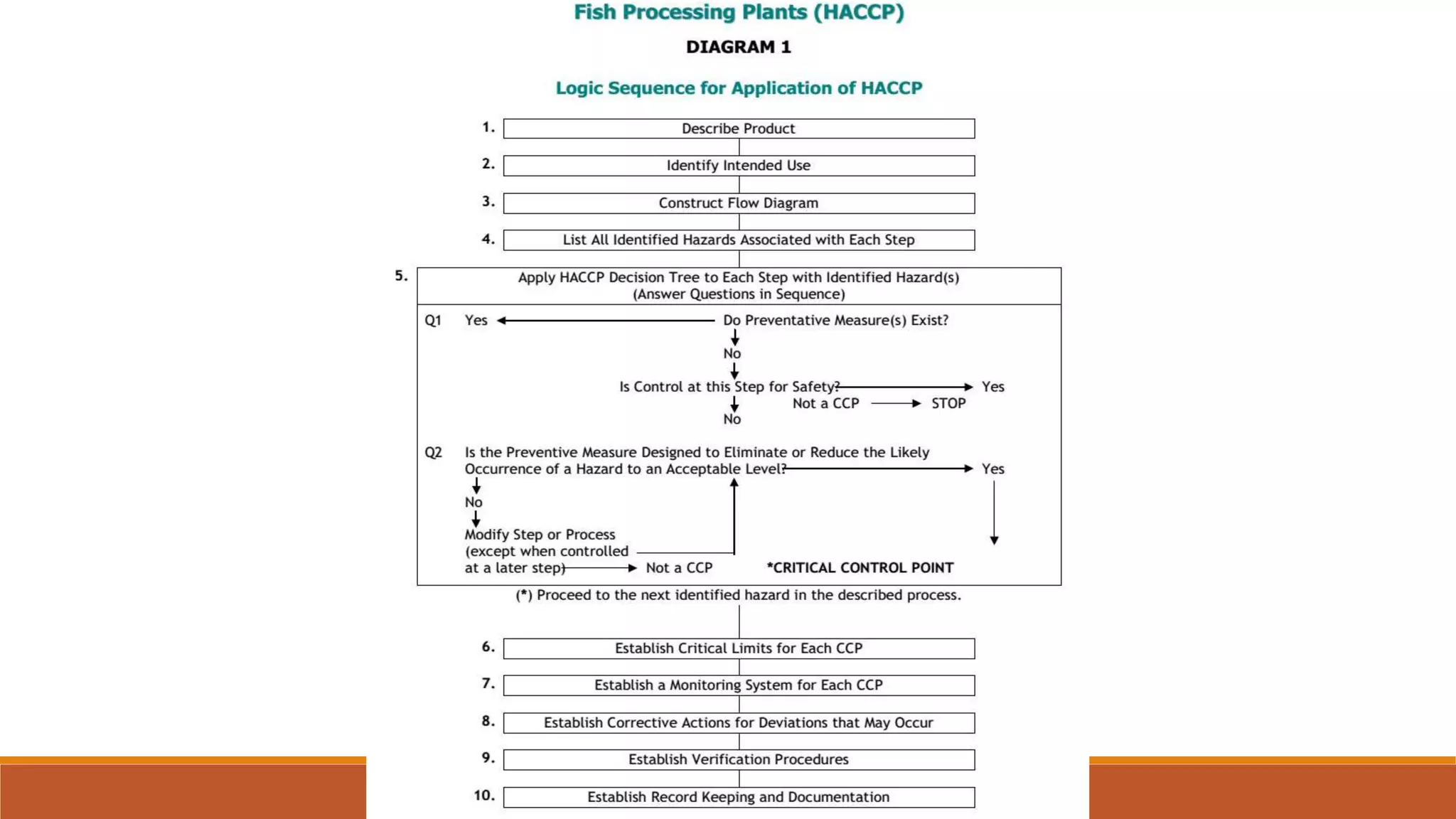

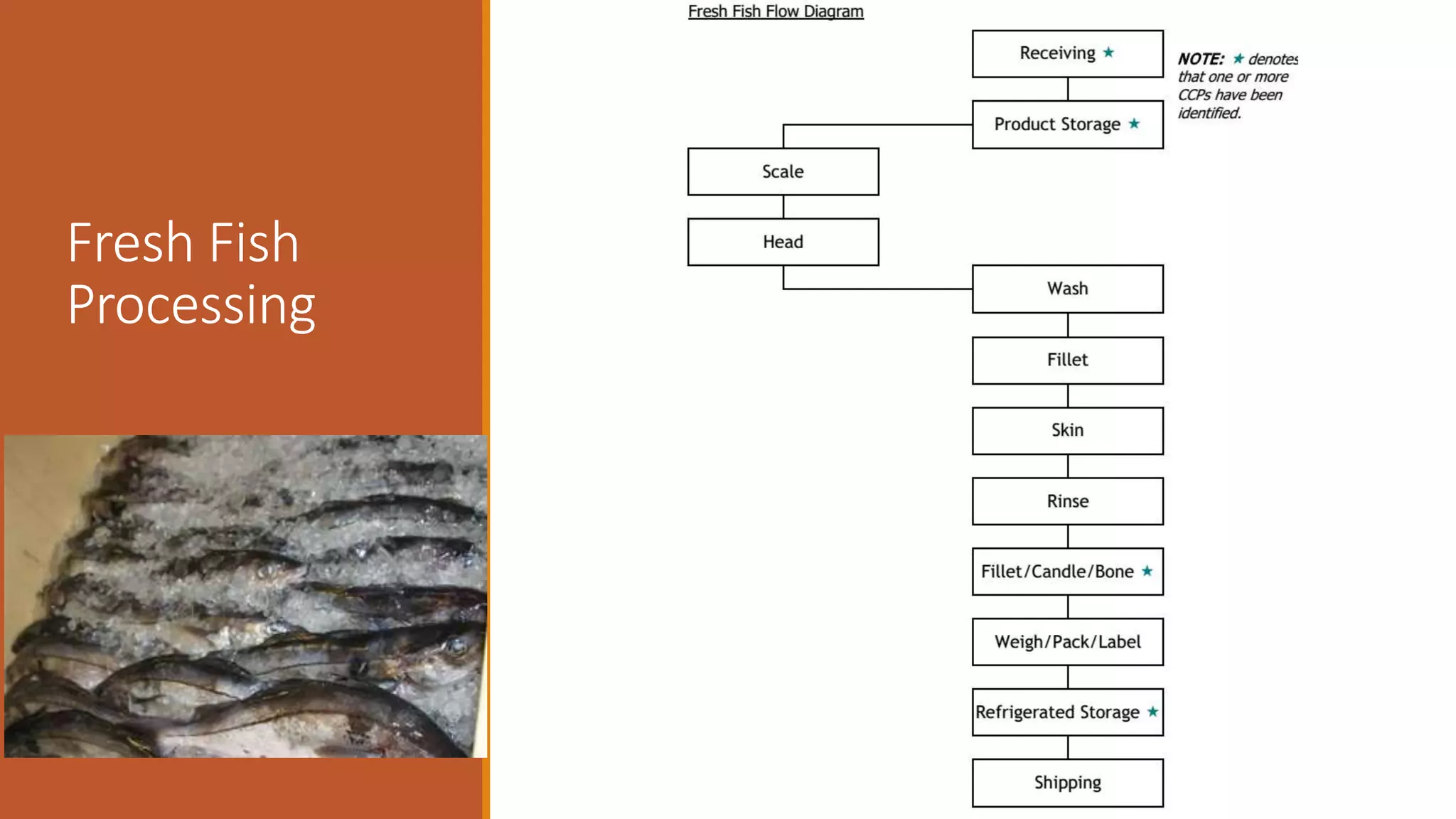

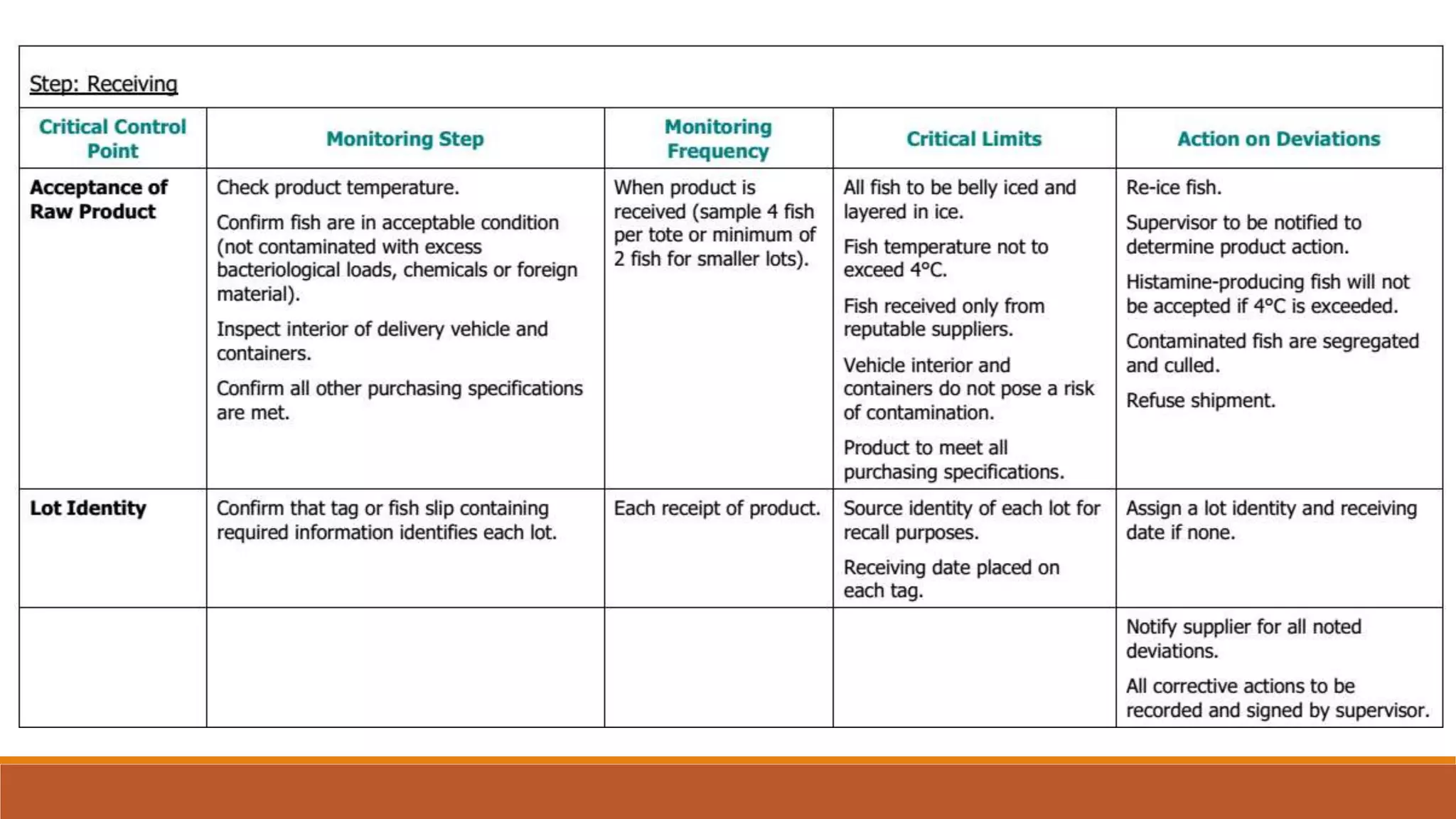

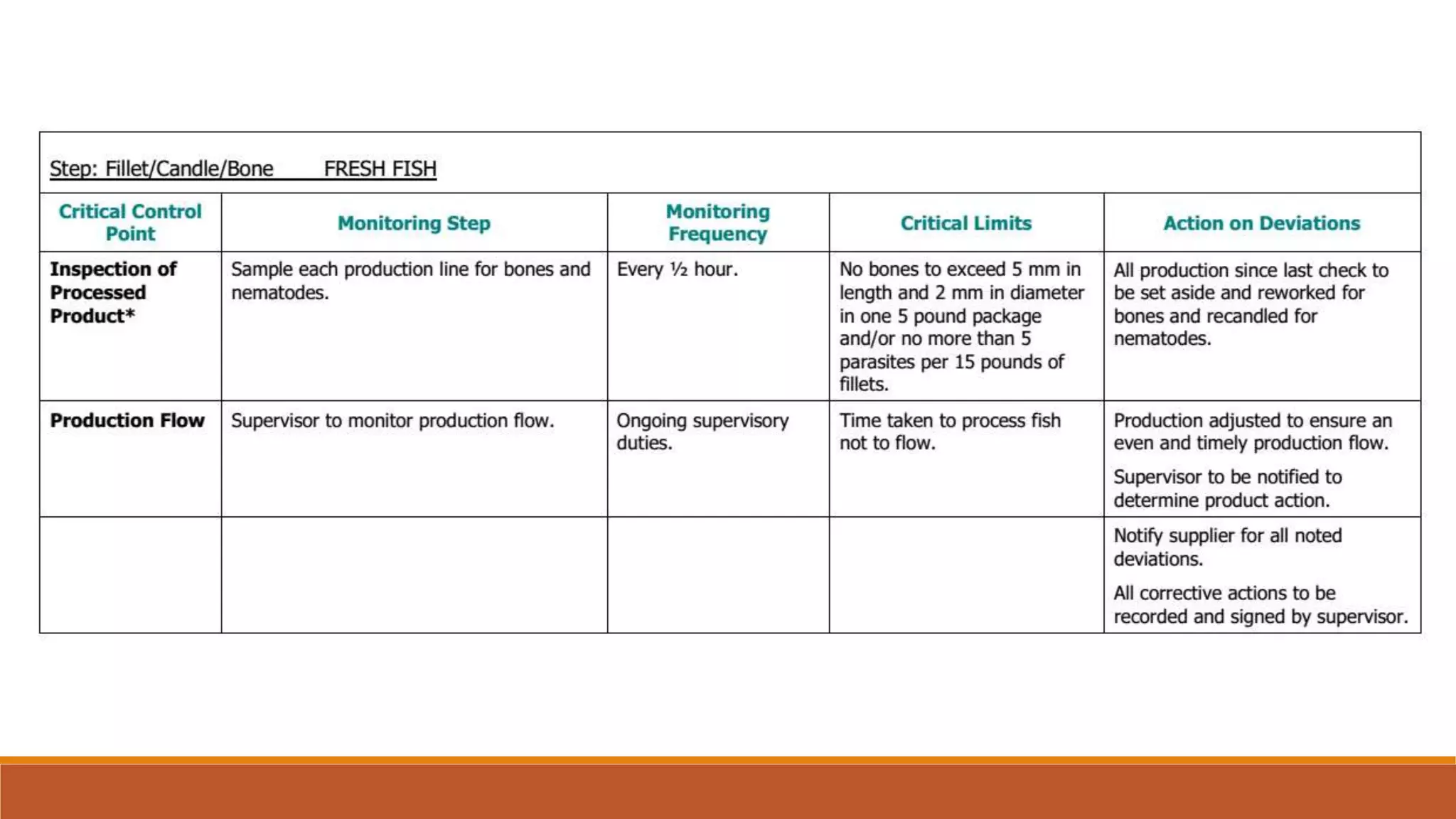

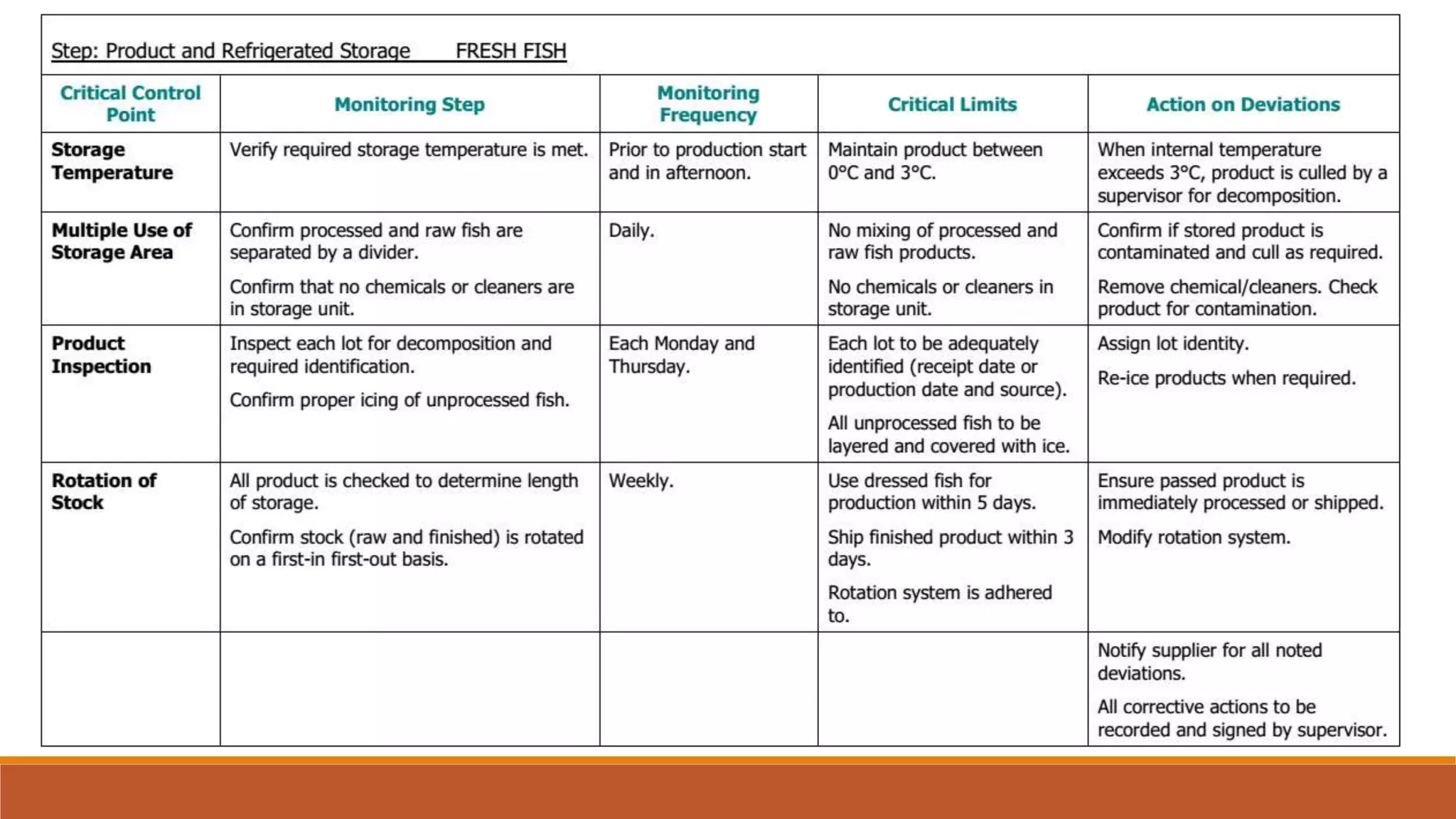

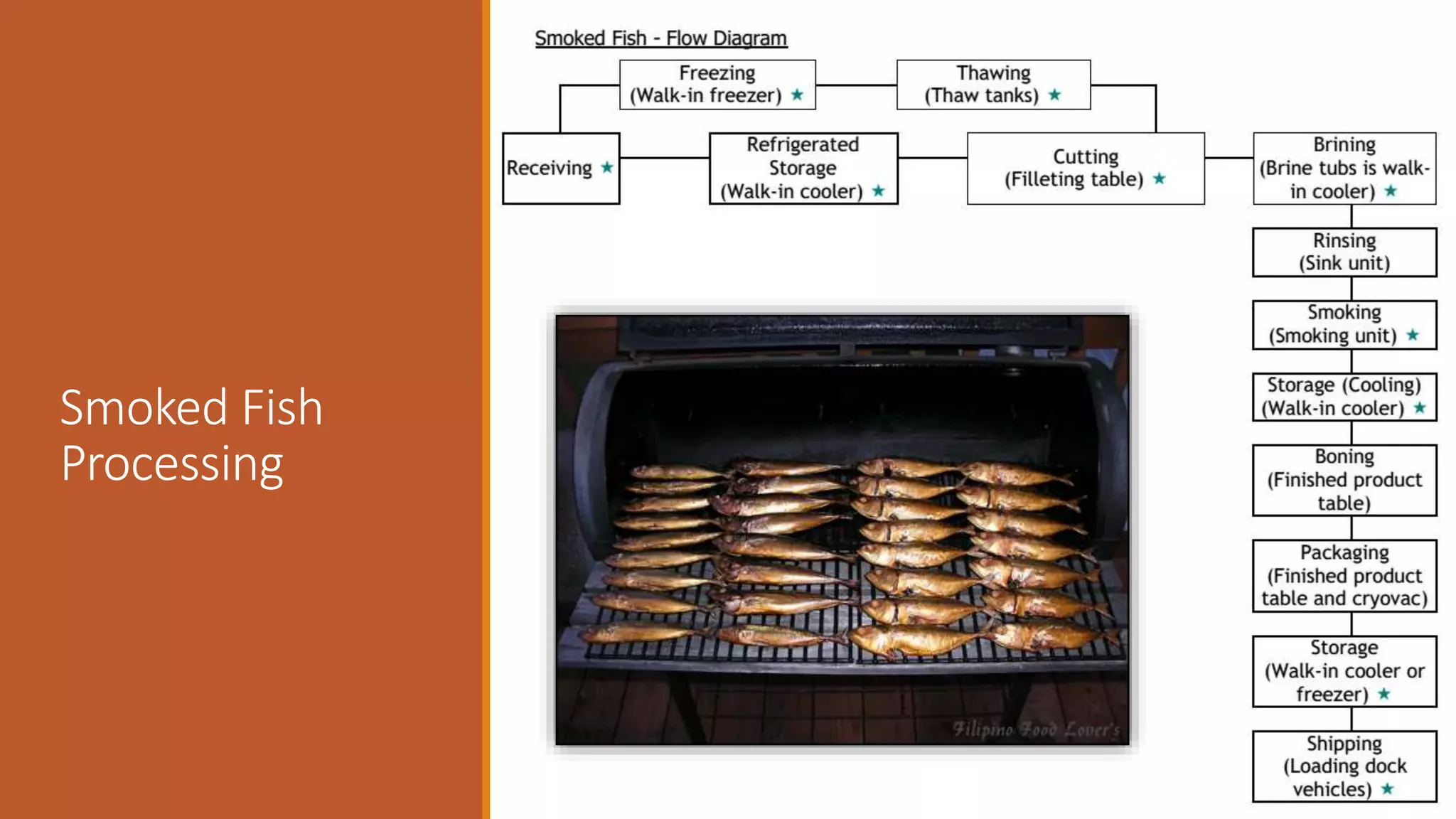

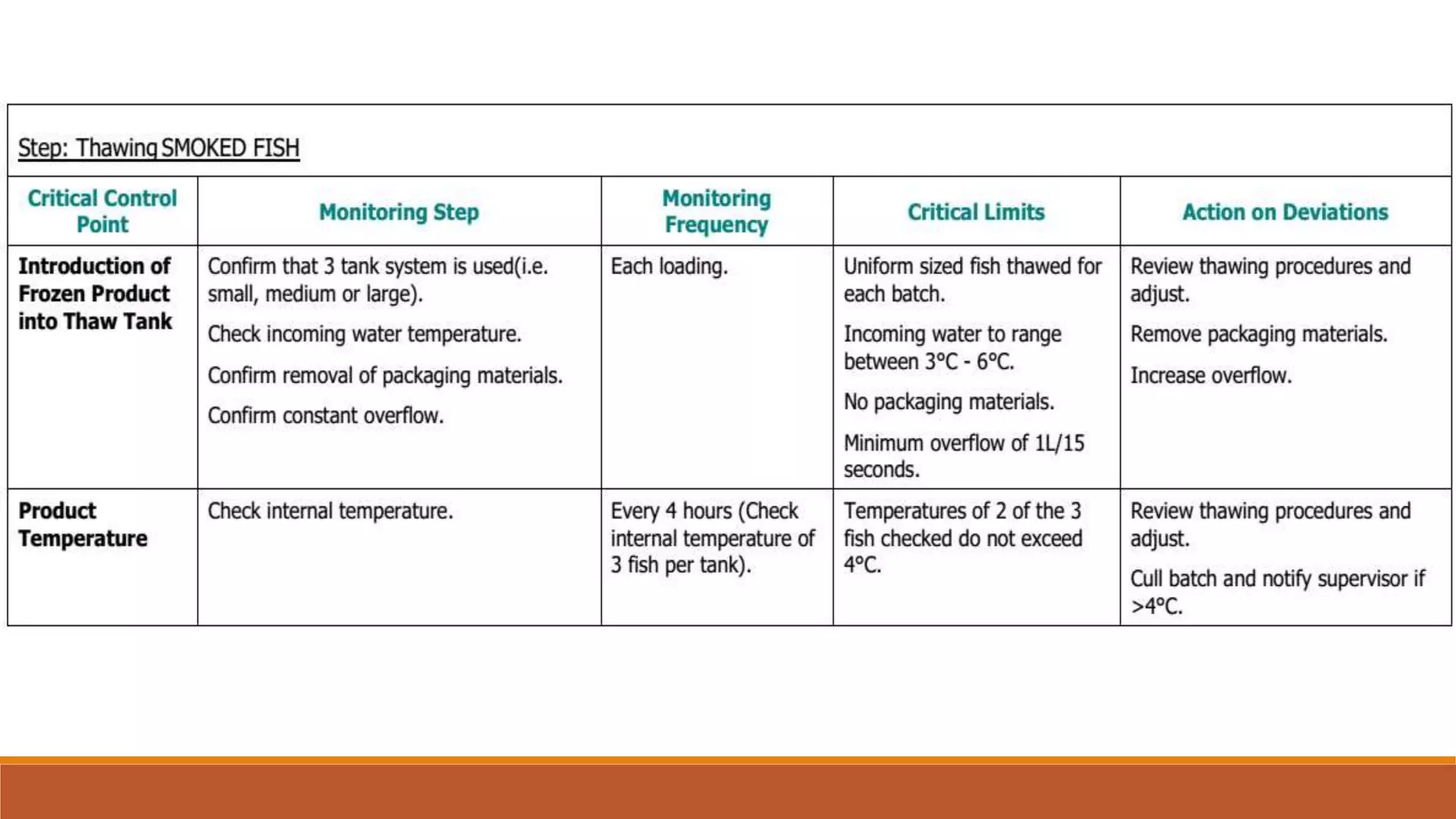

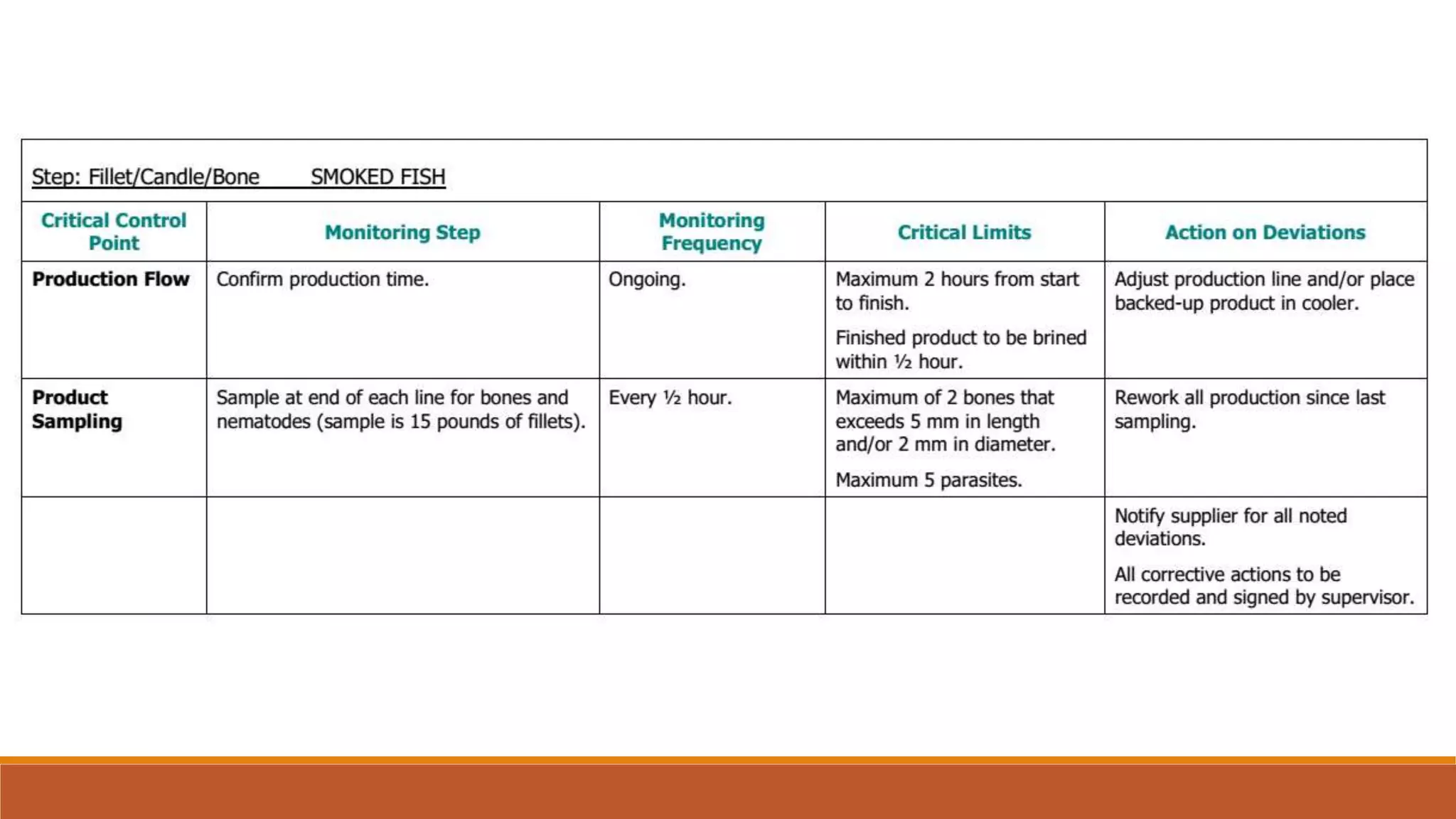

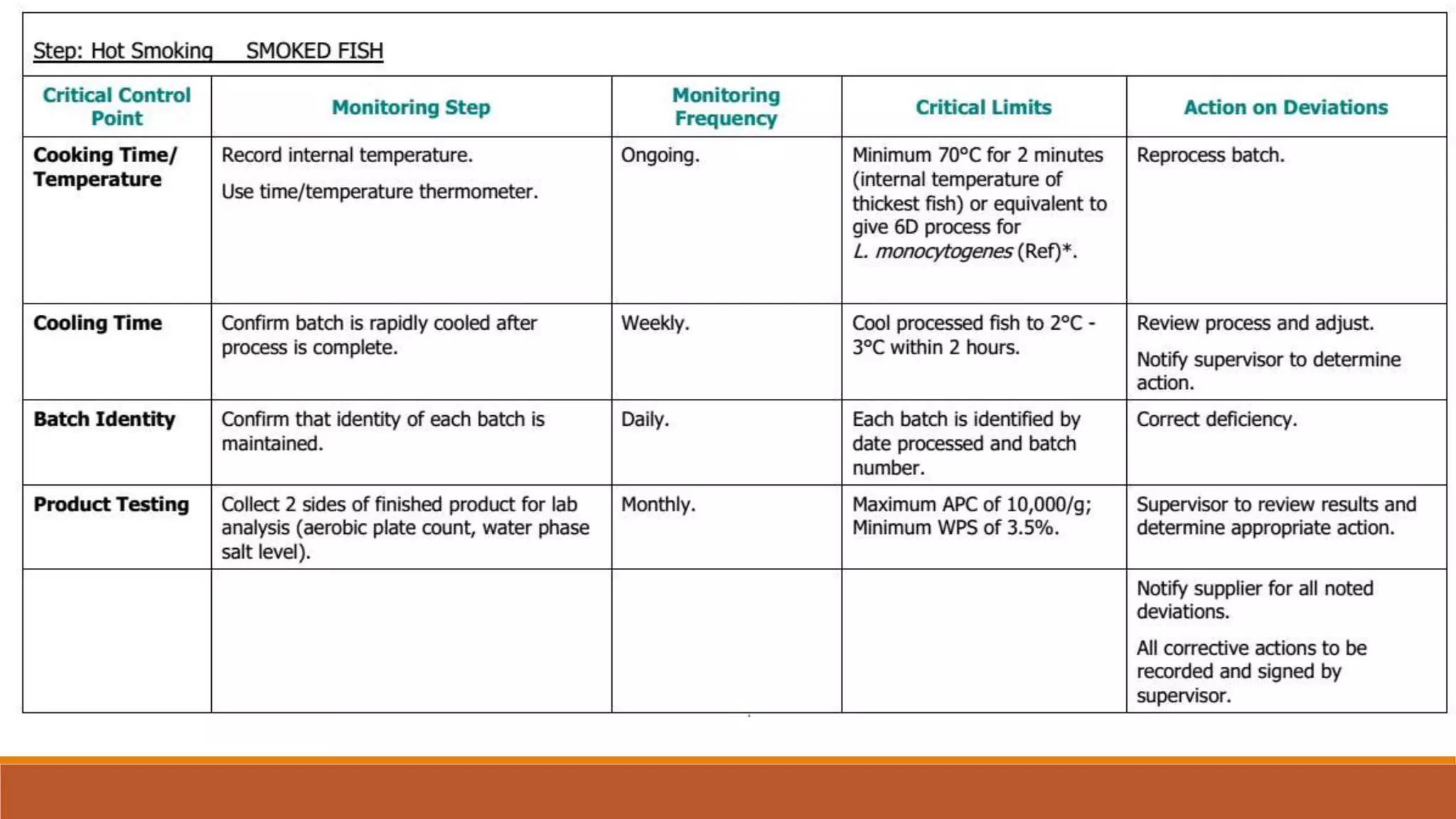

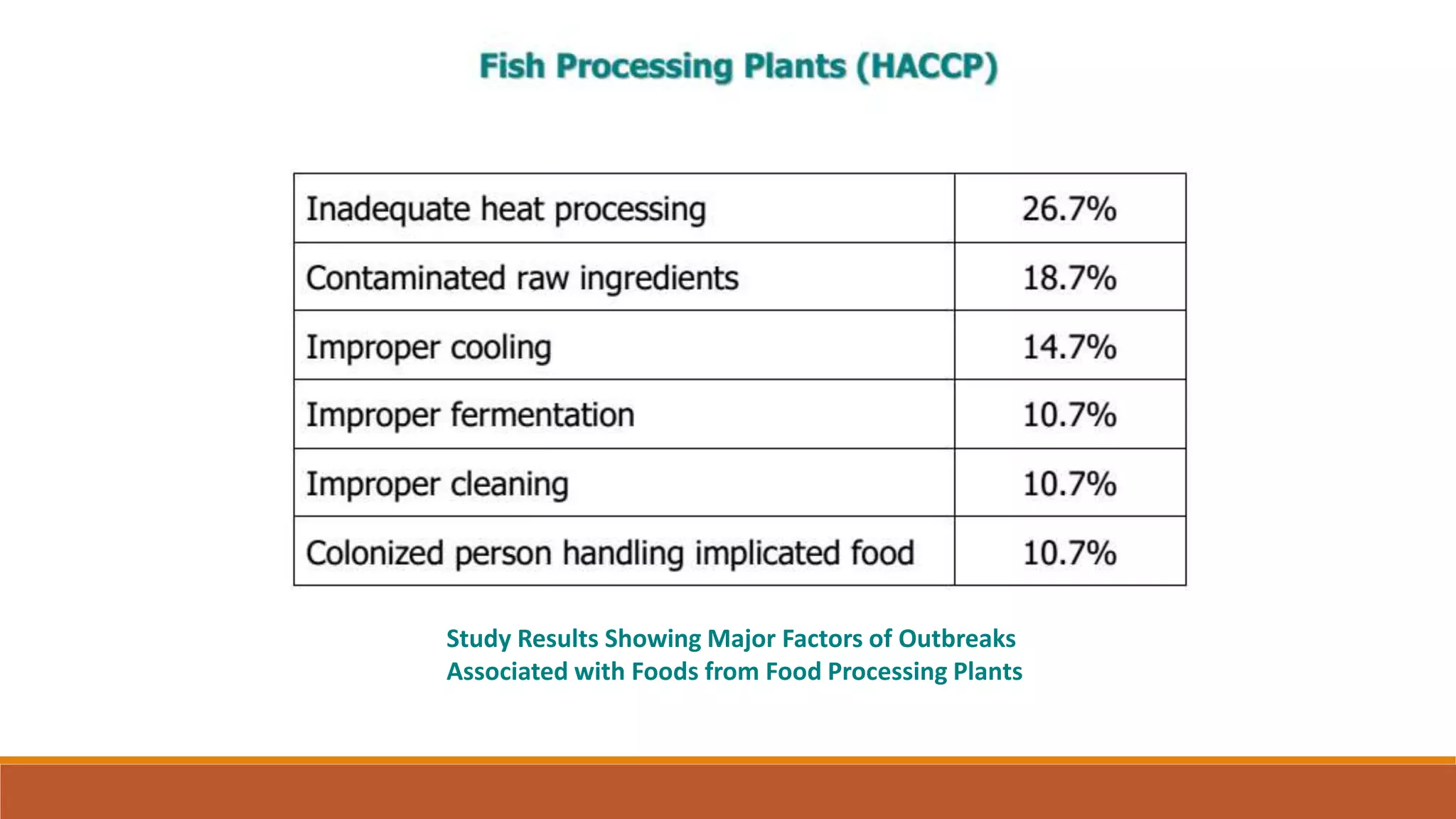

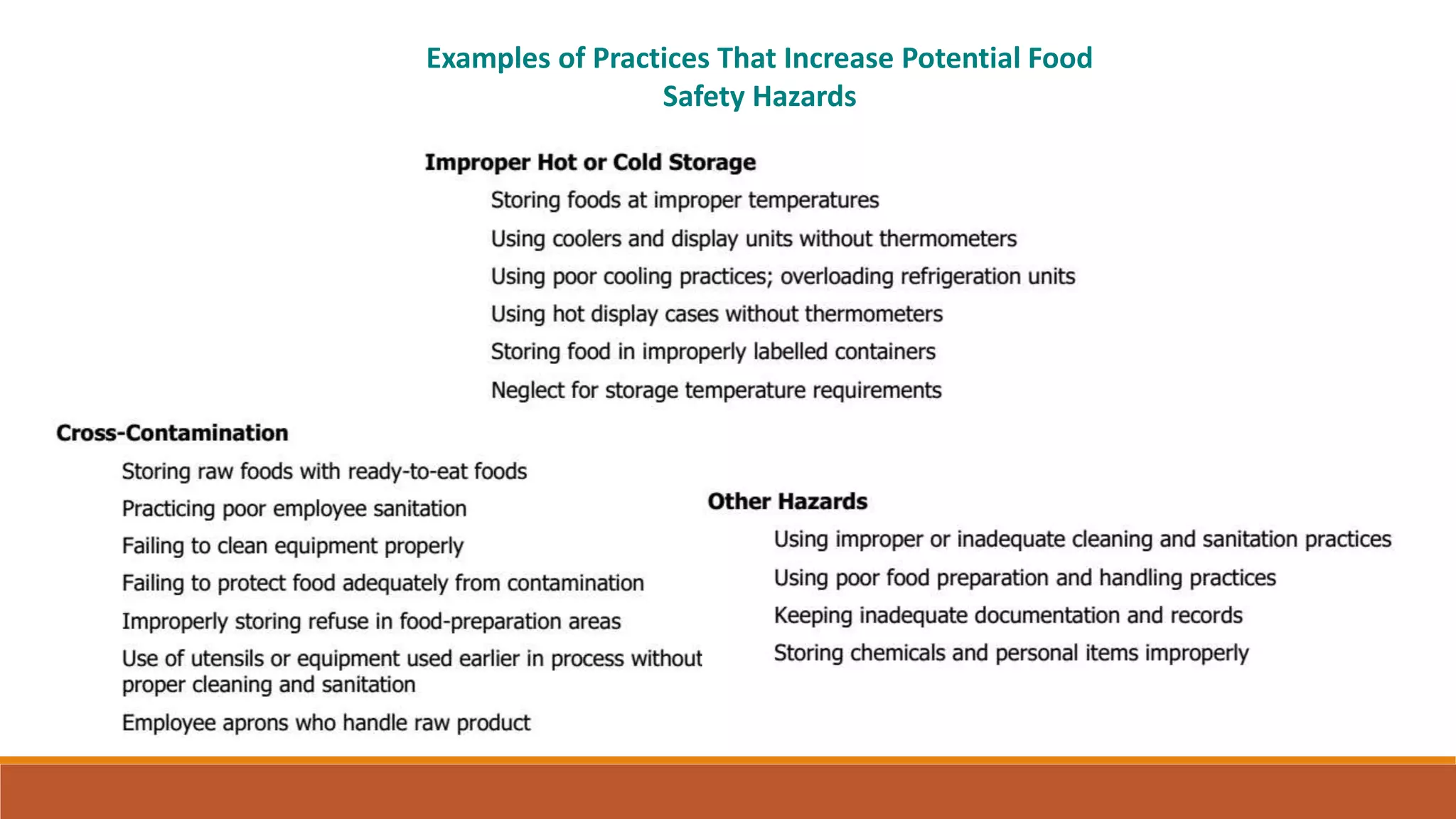

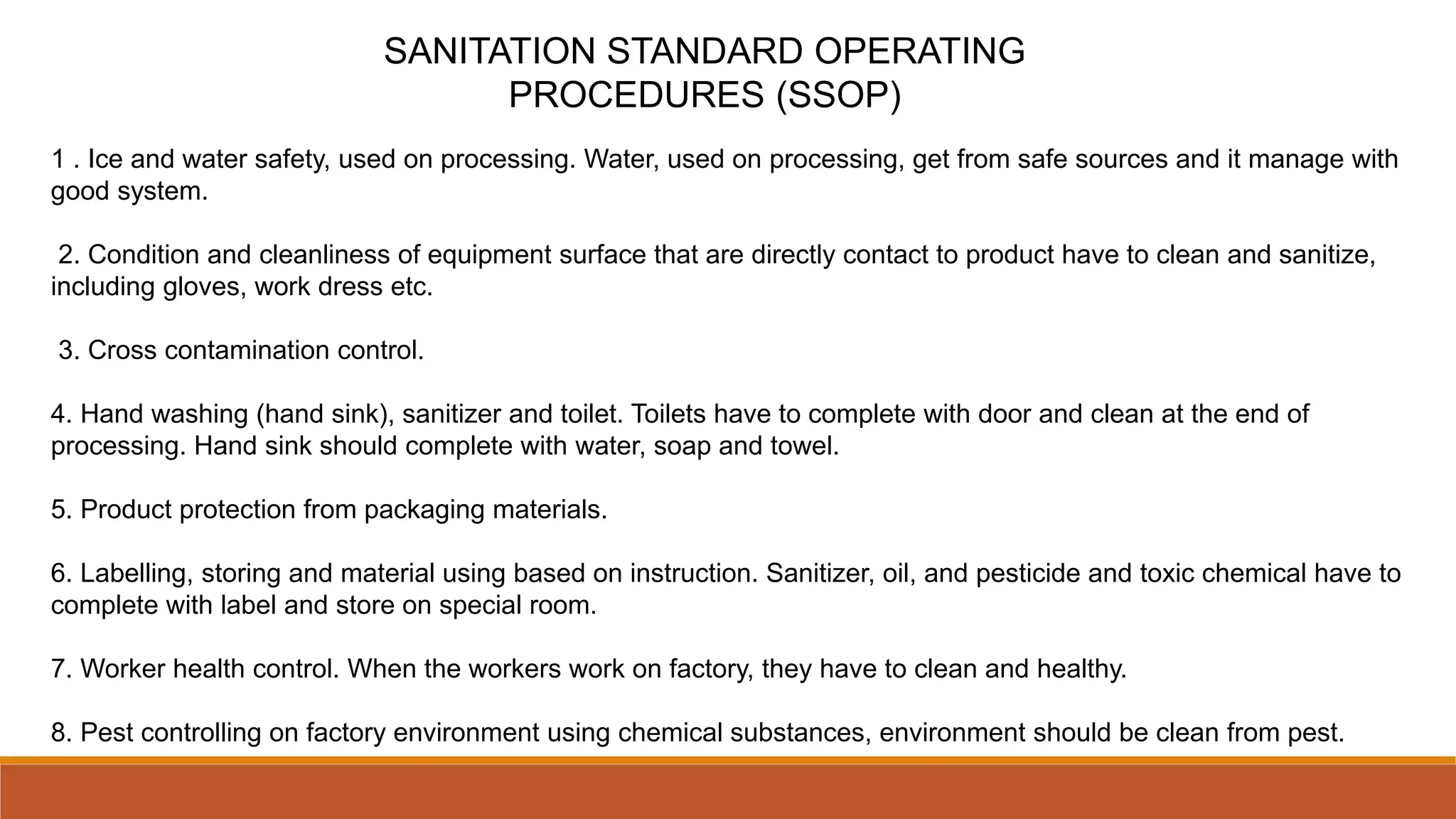

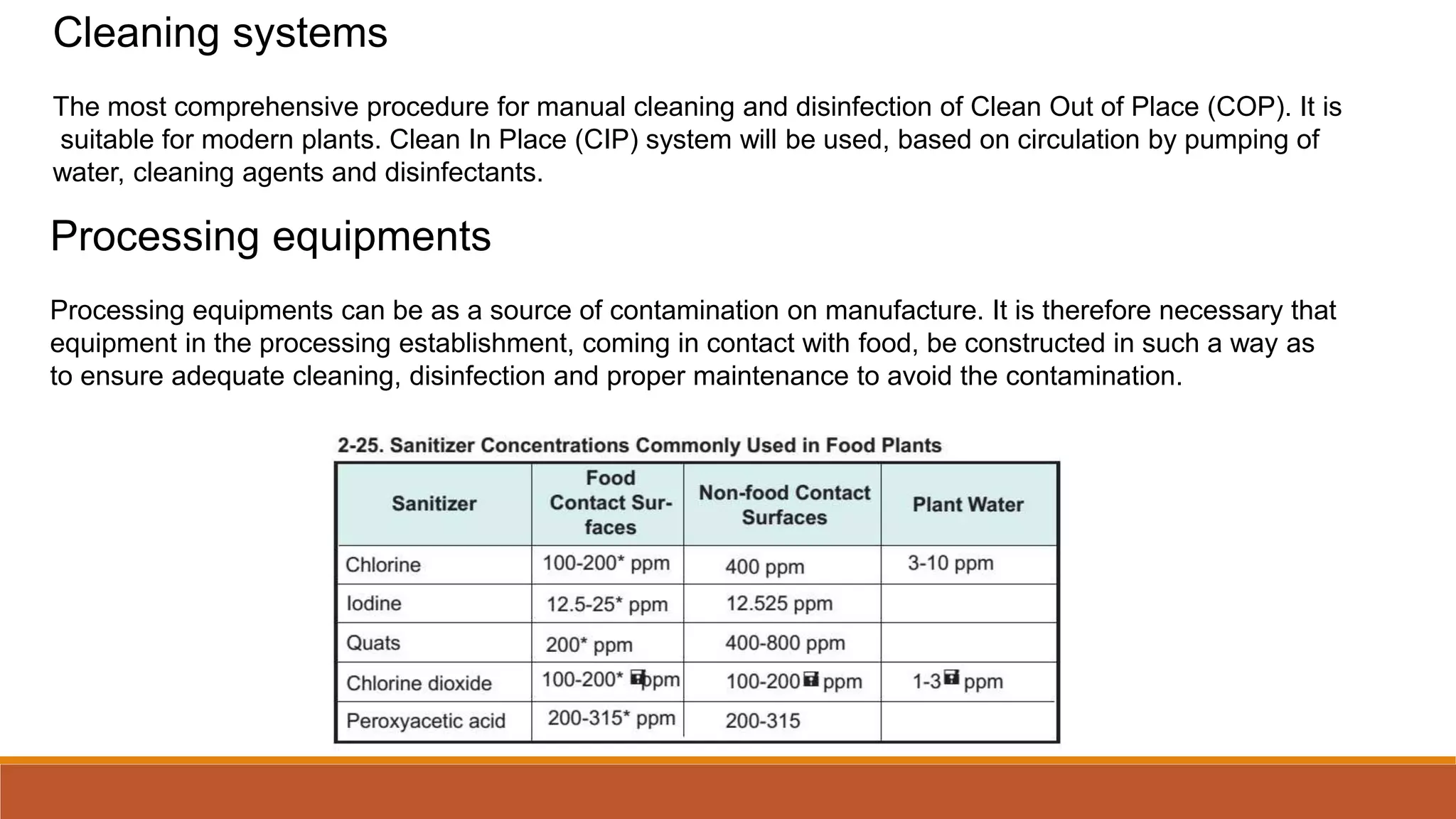

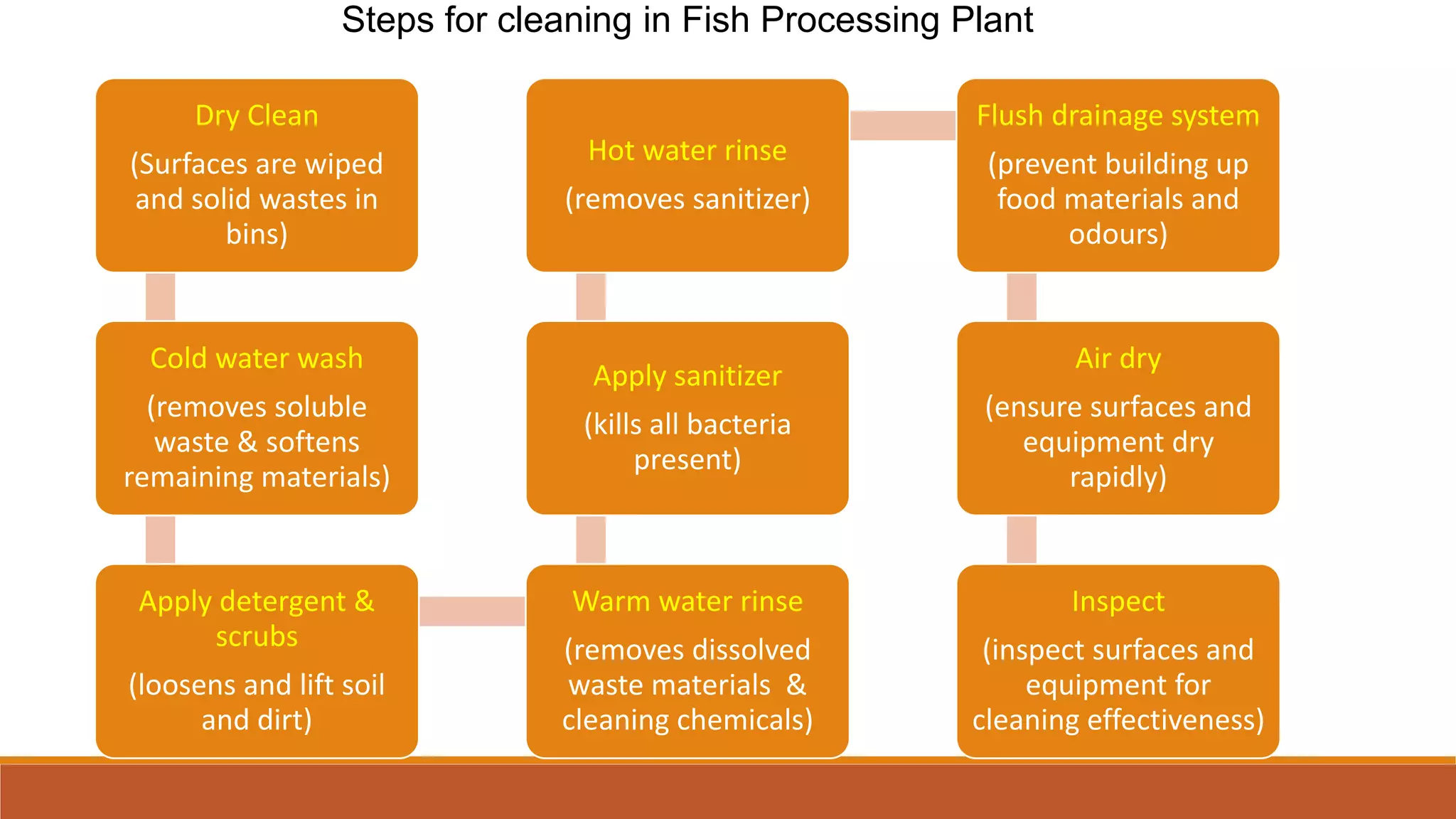

This document provides an overview of Hazard Analysis and Critical Control Point (HACCP) implementation in the fish processing industry. It discusses the preliminary processing steps of fish such as stunning, grading, scaling, washing, deheading, gutting, filleting, and skinning. It also describes HACCP principles, fresh and smoked fish processing, sanitation standard operating procedures, cleaning steps for a fish processing plant, and an example of a salmon processing industrial setup. The document is intended to educate about food safety practices and quality control in commercial fish processing.