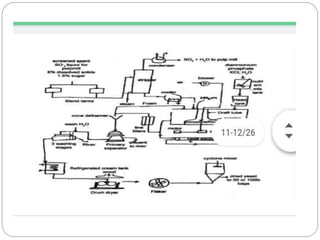

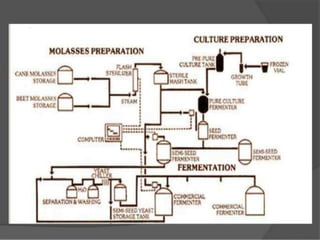

This document discusses the production of fodder yeast. Fodder yeast is a microbial protein produced by yeast that is used as animal feed. It has higher digestibility, amino acid content, and biological value than typical animal feeds. Fodder yeast is produced by fermenting waste or low-cost carbohydrate materials like molasses, wood sugars, or citrus juice using yeast strains like Candida utilis or Saccharomyces cerevisiae. The production process involves adding nutrients to the raw material, inoculating with yeast, aerating during fermentation, harvesting the yeast via centrifugation, and obtaining a dry yeast product with high protein content. Continuous fermentation systems and various raw materials can be used to produce