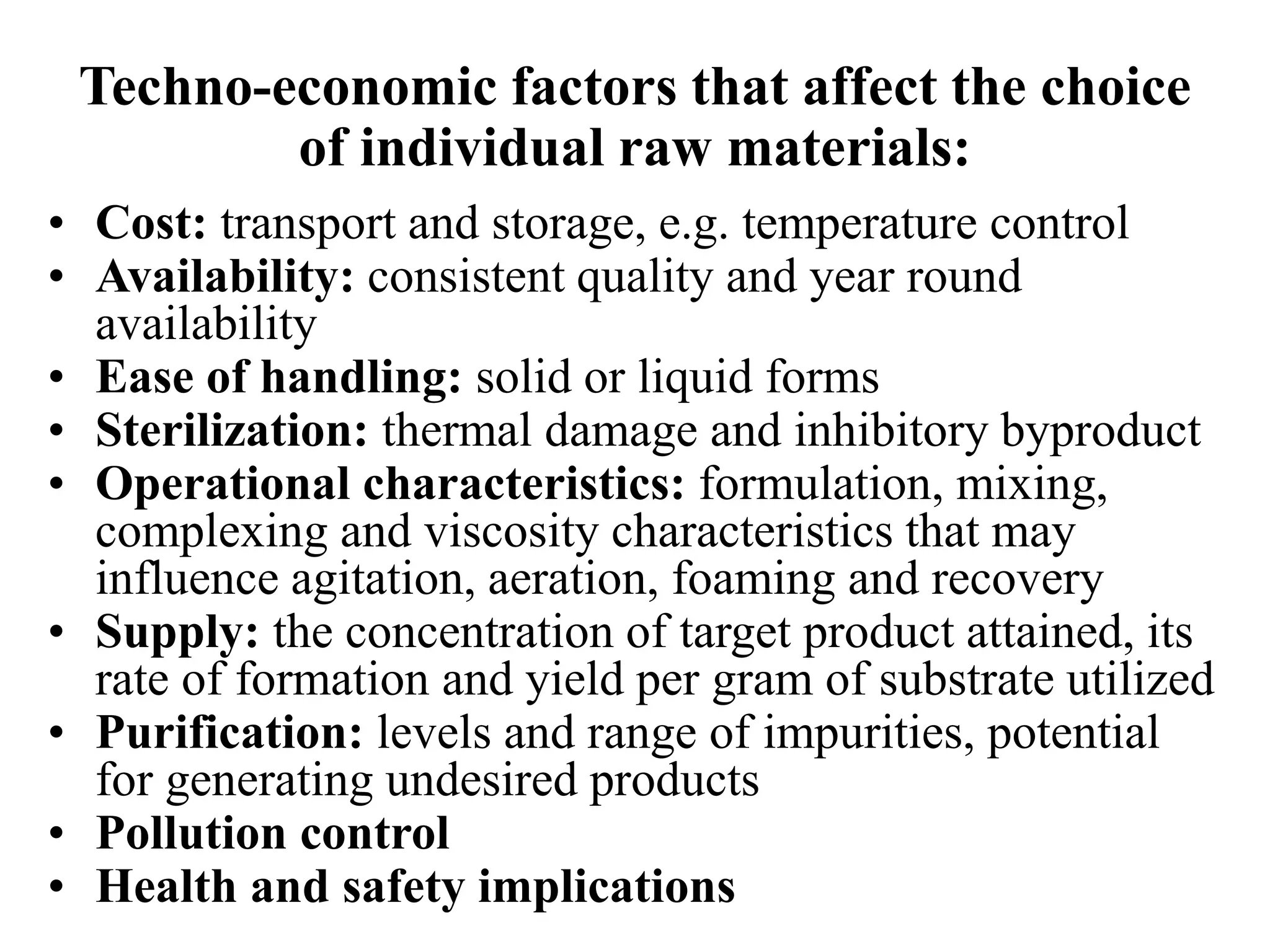

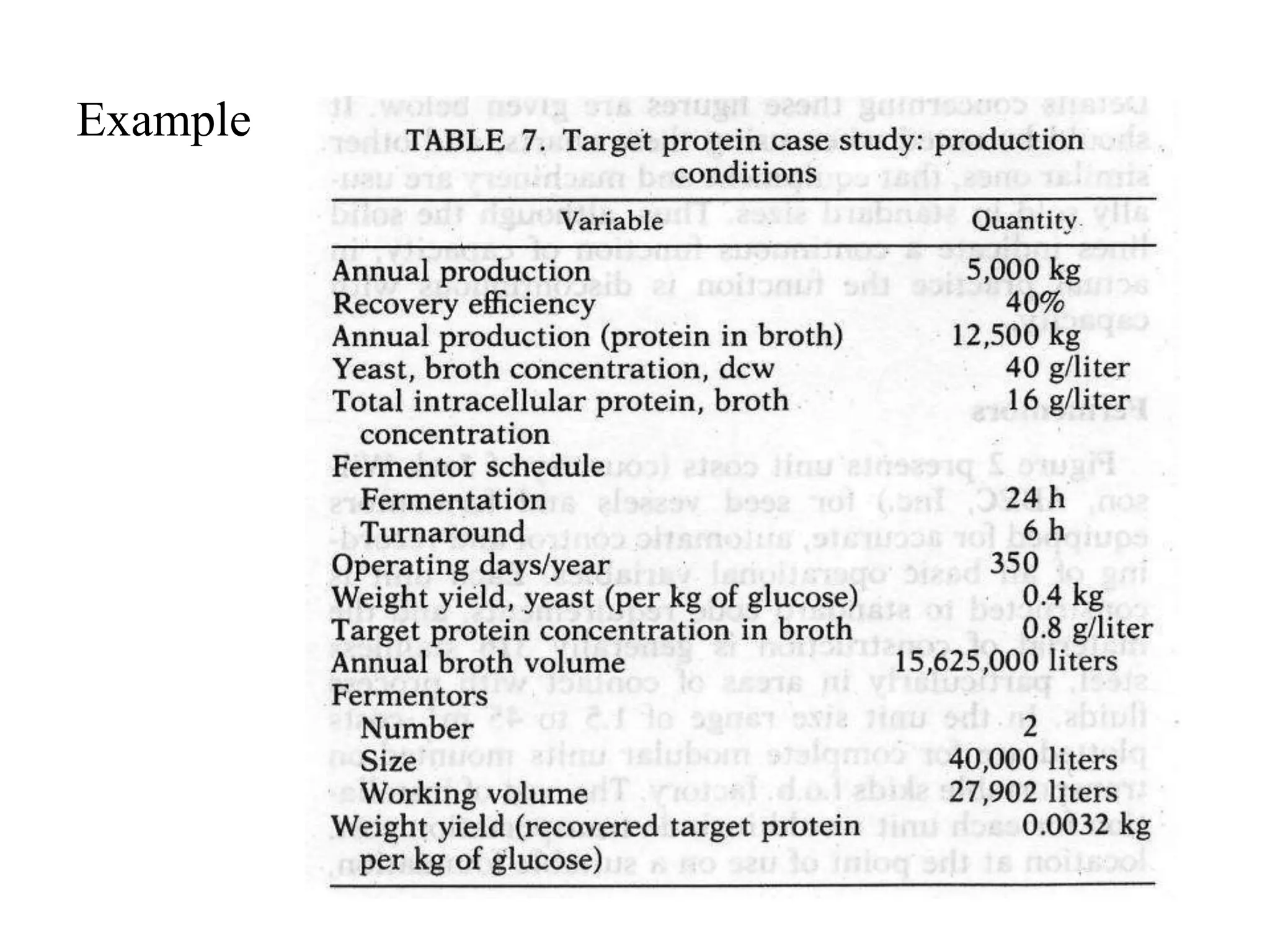

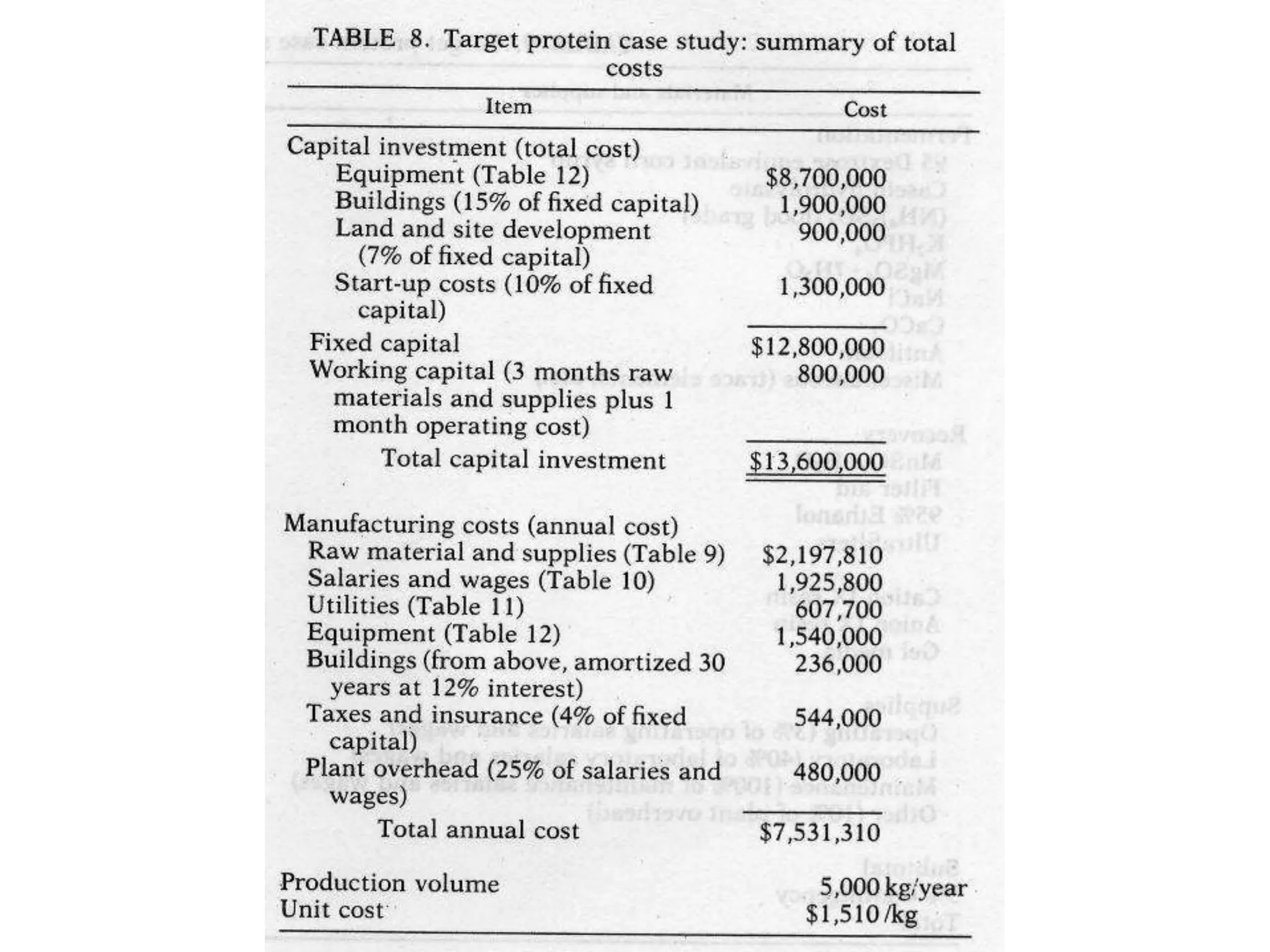

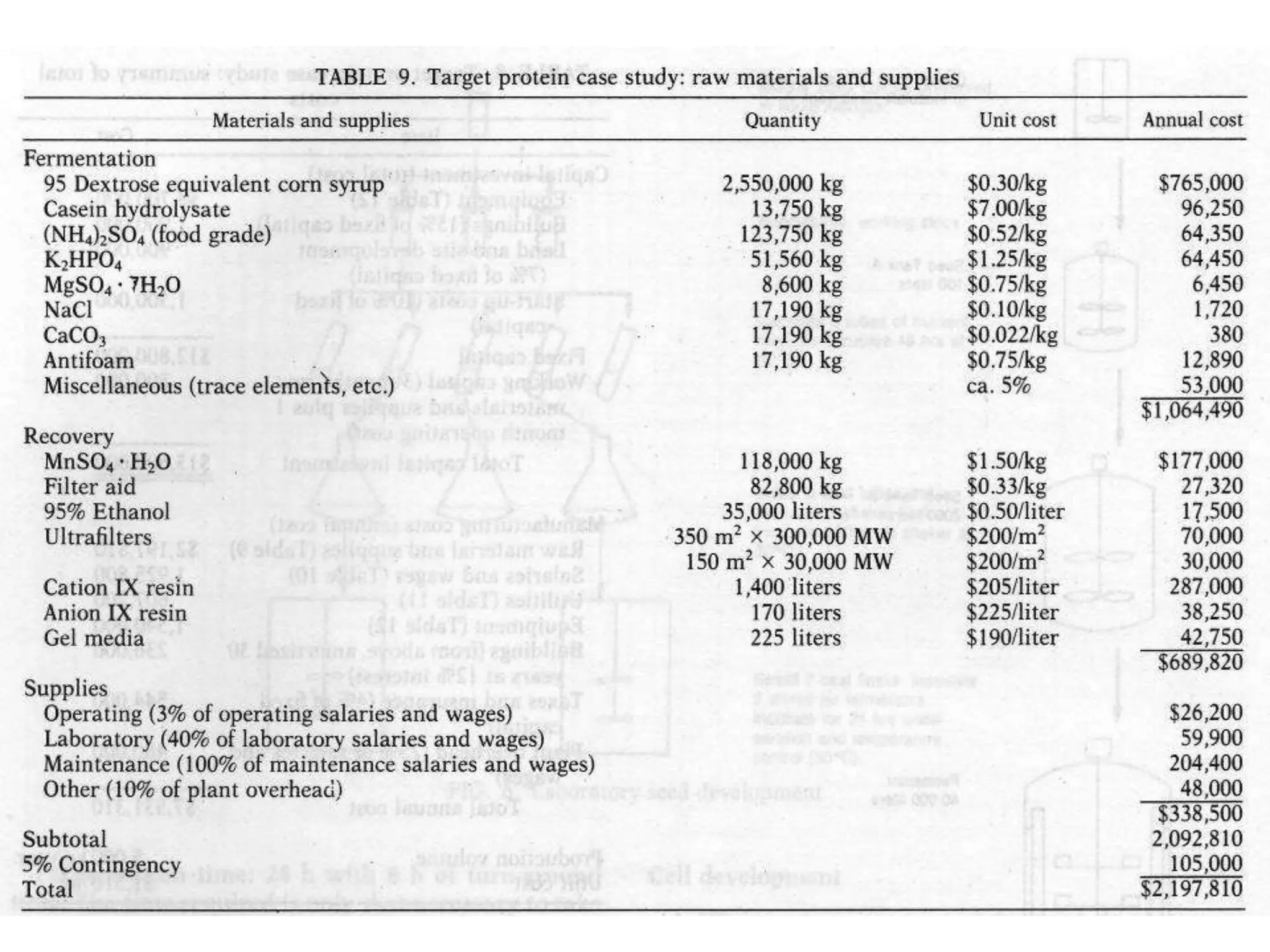

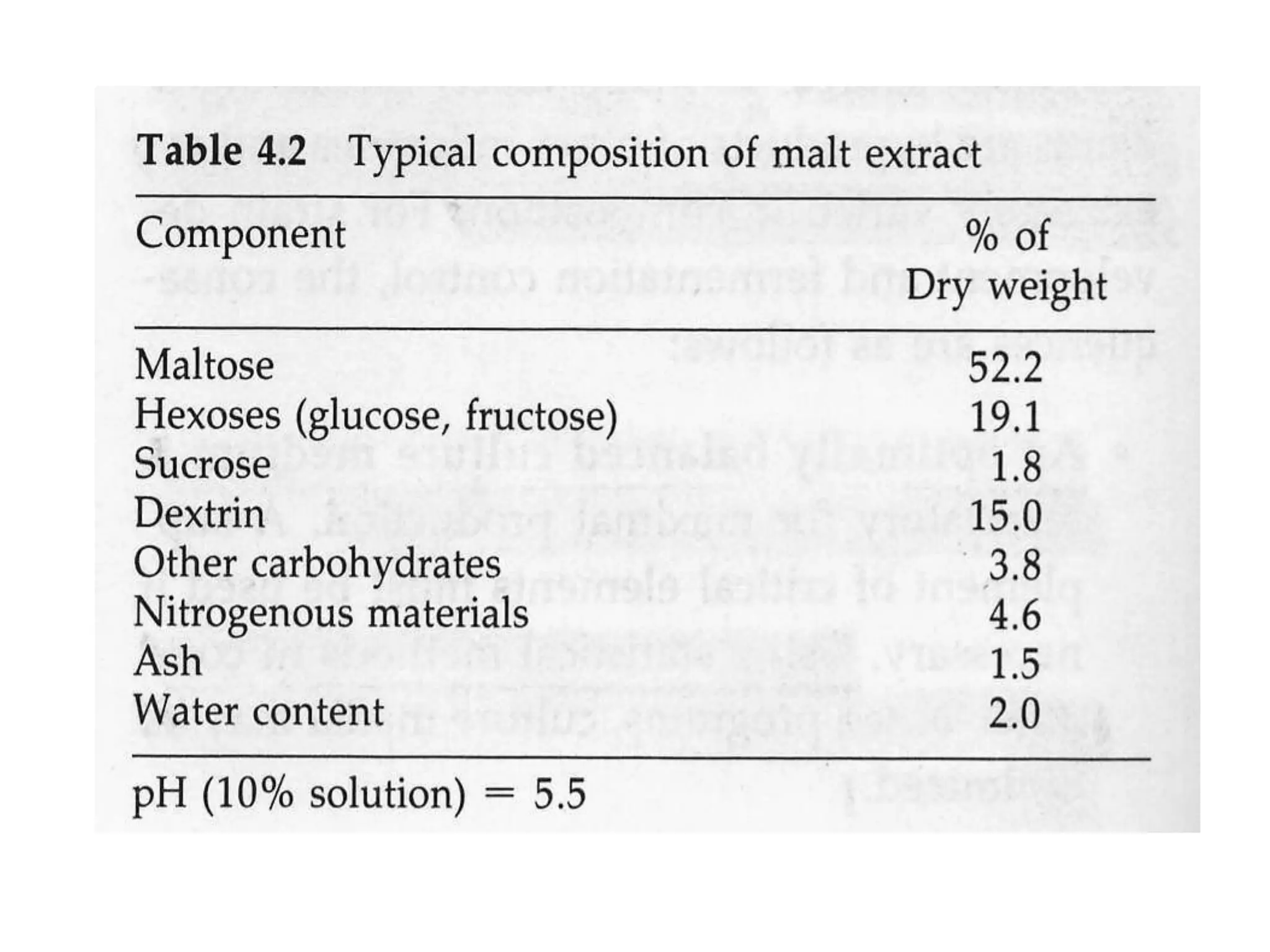

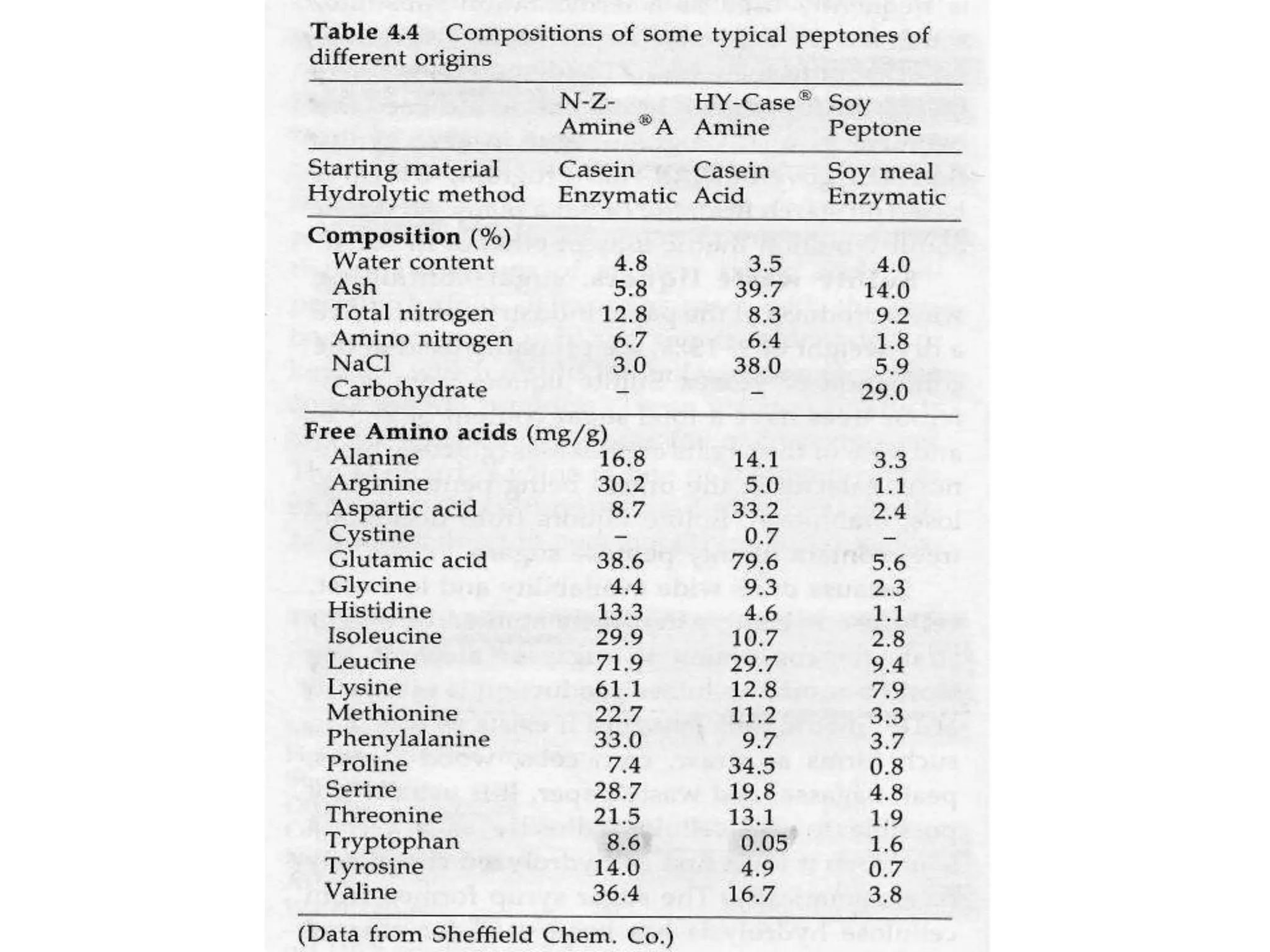

This document discusses various types of media used for fermentation processes. It describes defined media which uses minimal salts and has a known composition but is expensive. Crude media uses unrefined agricultural products and is cheaper but more variable. Common carbon sources discussed include molasses, malt extract, starch, cellulose and alcohols. Nitrogen sources mentioned are corn steep liquor, yeast extract, peptones and soybean meal. Other topics covered are antifoaming agents, water requirements, and considerations for seed cultures, production fermentations, and downstream processing.