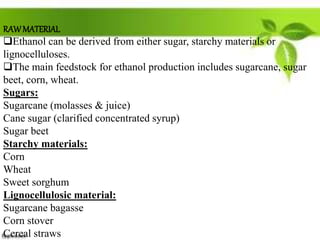

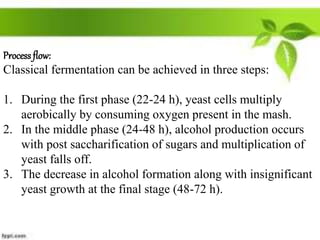

This document summarizes the process of ethanol production. It discusses that ethanol is produced through the fermentation of sugars or starches by yeast into ethanol and carbon dioxide. The key raw materials for ethanol production are discussed as sugarcane, corn, and wheat. The document outlines the steps in ethanol production as milling, liquefaction, saccharification, fermentation, distillation, and dehydration. Yeast and bacteria are used in the fermentation process to convert sugars into ethanol. Byproducts of ethanol production like dried distillers grains and carbon dioxide are also mentioned.