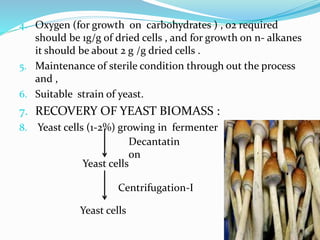

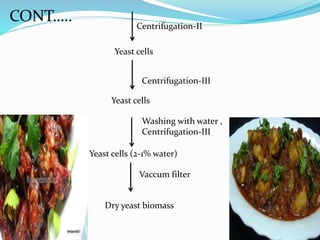

This document discusses microbial biomass production through baker's yeast, single cell protein, and mushrooms. It provides details on the production processes and advantages of each. Baker's yeast is produced through fermentation of molasses and yields 0.4 million metric tonnes annually. Single cell protein production uses alternative waste sources like cellulosic material. Mushrooms are a protein-rich food produced through fermentation of lignocellulose materials and yield environmental benefits.